Back contact heterojunction solar battery

A solar cell and heterojunction technology, applied in the field of solar cells, can solve the problems of increasing the density of carrier recombination defects, affecting the collection and transmission of photo-generated current, and affecting the conversion efficiency of solar cells, so as to improve the photoelectric conversion efficiency and current. , the effect of improving the conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and examples, but the present invention is not limited thereto.

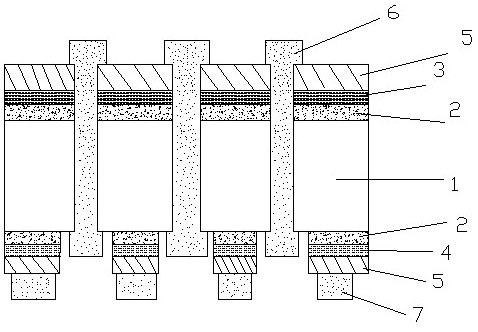

[0028] Such as figure 1 As shown, this embodiment one

[0029] The N-type crystalline silicon 1 is made of an N-type single crystal silicon wafer, and the surface of the N-type crystalline silicon 1 is pre-cleaned and textured by using a semiconductor cleaning process. The thickness of the N-type crystalline silicon 1 used is 200um, the resistivity is 0.5~3Ω.cm, the silicon dioxide layer on the surface of the N-type crystalline silicon 1 is removed with 1~5% hydrofluoric acid, and the concentration is less than 3% NaOH and IPA (isopropanol) mixed liquid at about 80°C to prepare pyramid-shaped suede. Increase the absorption of sunlight, increase the area of the PN junction, and increase the short-circuit current. The subsequent N-type crystalline silicon 1 is cleaned by an acid cleani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com