Honing machine spindle reciprocating follow-up control toothed belt driving device

A technology of toothed belt drive and honing machine, which is applied in the direction of grinding drive device, honing machine tool, workpiece feed movement control, etc. Commissioning, maintenance and other problems are cumbersome, to achieve the effect of reducing technical requirements and simplifying commissioning and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

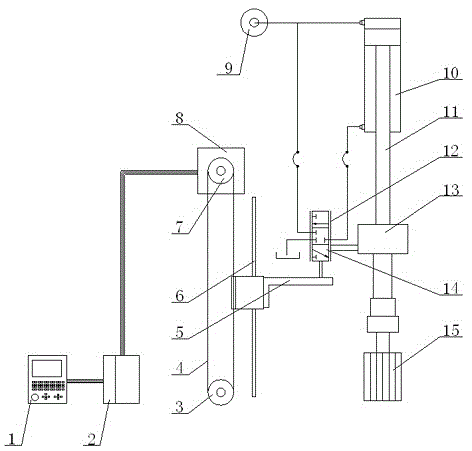

[0018] Such as figure 1 As shown, the spindle hydraulic cylinder 10 that drives the main shaft of the honing machine to reciprocate, the servo motor, and the linear guide rail 6 that ensures the stability of the connecting piece 5 moving up and down, the linear guide rail 6 is installed on the bed of the honing machine, and the connecting piece 5 is installed on the linear guide rail .

[0019] As shown in the figure, 1 is a digital controller, 2 is a servo driver, and 8 is a servo motor. The digital controller, the servo driver and the servo motor are connected through cables. According to the displacement requirements of the hydraulic cylinder 10, the digital controller is used for setting. The pressure of the hydraulic system is provided by the hydraulic pump 9 .

[0020] When working, according to the set program, the servo driver issues instructions to make the servo motor rotate clockwise, through the active toothed pulley 7 installed on the output shaft of the servo mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com