Process for treating wastewater generated in neopentyl glycol production

A neopentyl glycol and wastewater treatment technology, applied in natural water treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of low microbial treatment efficiency, affecting microbial treatment, and microbial inability to survive and other problems, to achieve the effect of low comprehensive treatment cost, reduced infrastructure costs, and less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

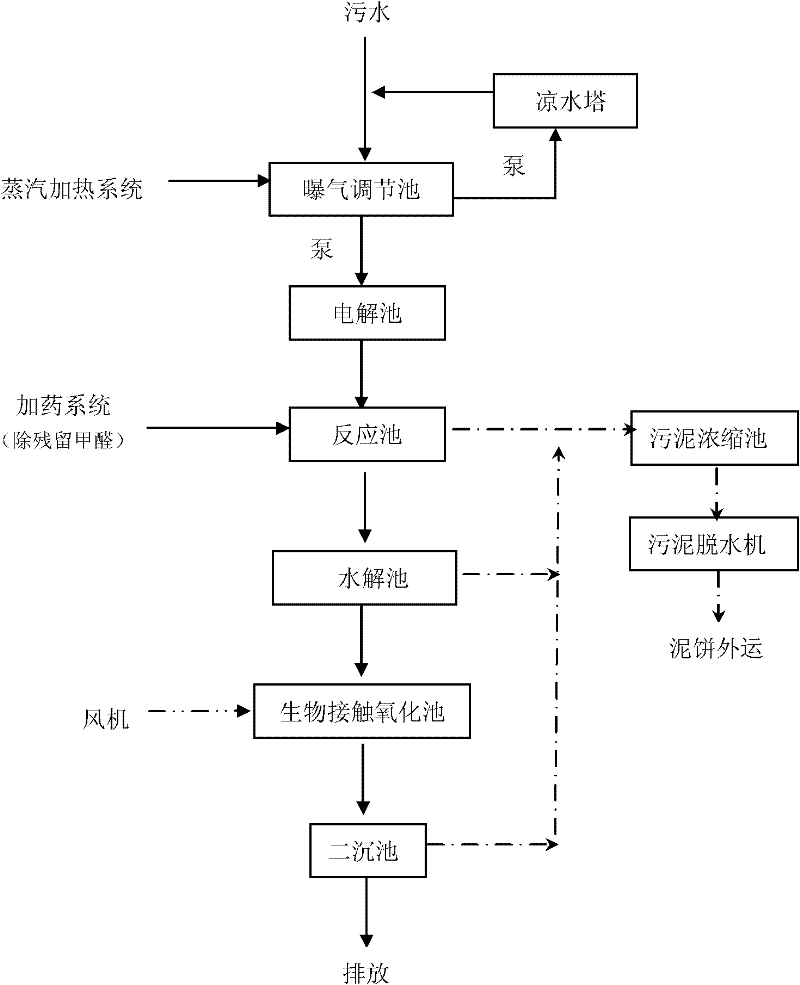

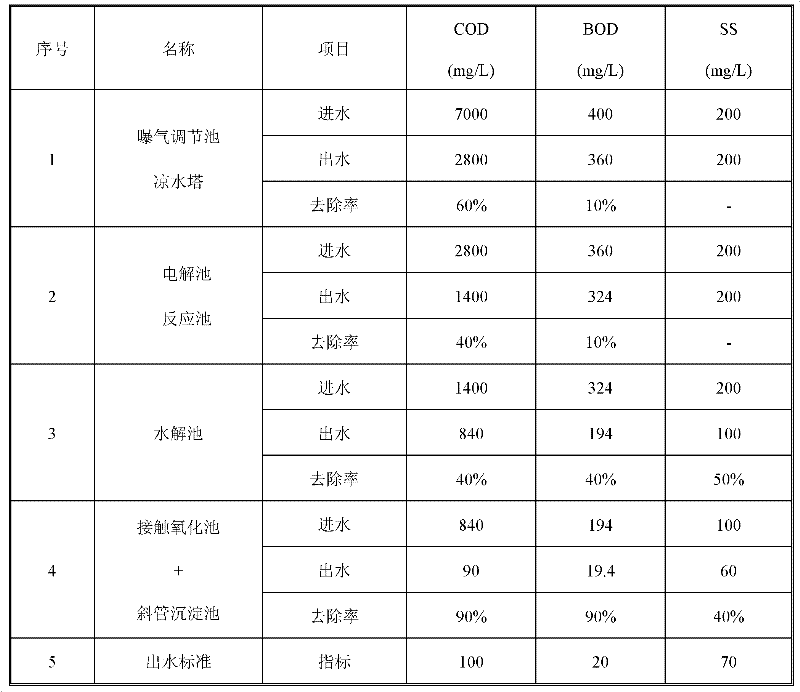

[0025] Project implementation, sewage system operation, wastewater treatment process for neopentyl glycol production:

[0026] The neopentyl glycol wastewater first enters the aeration regulating tank, and the wastewater is homogeneously adjusted by the air stirring system installed in the tank, and then lifted to the cooling tower by the pump to remove most of the formaldehyde in the wastewater. The specific requirements for steam blowing : Inlet water temperature 40~50℃, counter-flow FRP cooling tower, power: 4.0KW.

[0027] The water from the cooling tower is then electrolyzed and chemical agents are used to remove the residual formaldehyde in the wastewater, so that the concentration of formaldehyde in the wastewater is reduced to below 3mg / L. The specific requirements of the electrolytic cell: electrolytic DC voltage: 36V, residence time: 1h, distance between electrode plates: 300mm ; The chemical agent is a mixture of hydrogen peroxide and ferrous sulfate, dosage: hydrog...

Embodiment 2

[0031] Wastewater treatment process for neopentyl glycol production:

[0032] The neopentyl glycol wastewater first enters the aeration regulating tank, and the wastewater is homogeneously adjusted by the air stirring system installed in the tank, and then lifted to the cooling tower by the pump to remove most of the formaldehyde in the wastewater. The specific requirements for steam blowing : Inlet water temperature 40~50℃, counter-flow FRP cooling tower, power: 4.0KW.

[0033] The water from the cooling tower is then electrolyzed and chemical agents are used to remove the residual formaldehyde in the wastewater, so that the concentration of formaldehyde in the wastewater is reduced to below 3mg / L. The specific requirements of the electrolytic cell: electrolytic DC voltage: 36V, residence time: 1h, distance between electrode plates: 300mm ; The chemical agent is a mixture of hydrogen peroxide and ferrous sulfate, dosage: hydrogen peroxide: 150mg / L, ferrous sulfate: 60mg / L, re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com