Reaction equipment of biomass engine gas for vehicle

A vehicle engine and reaction equipment technology, which is applied in the field of biomass high-temperature catalytic cracking and dry distillation gas reaction devices, can solve the problems of not being able to completely become a substitute for petroleum products, slow development of alternative energy, economic and environmental damage, etc., and achieve vehicle climbing power. Excellent performance, no abnormal phenomenon, high calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

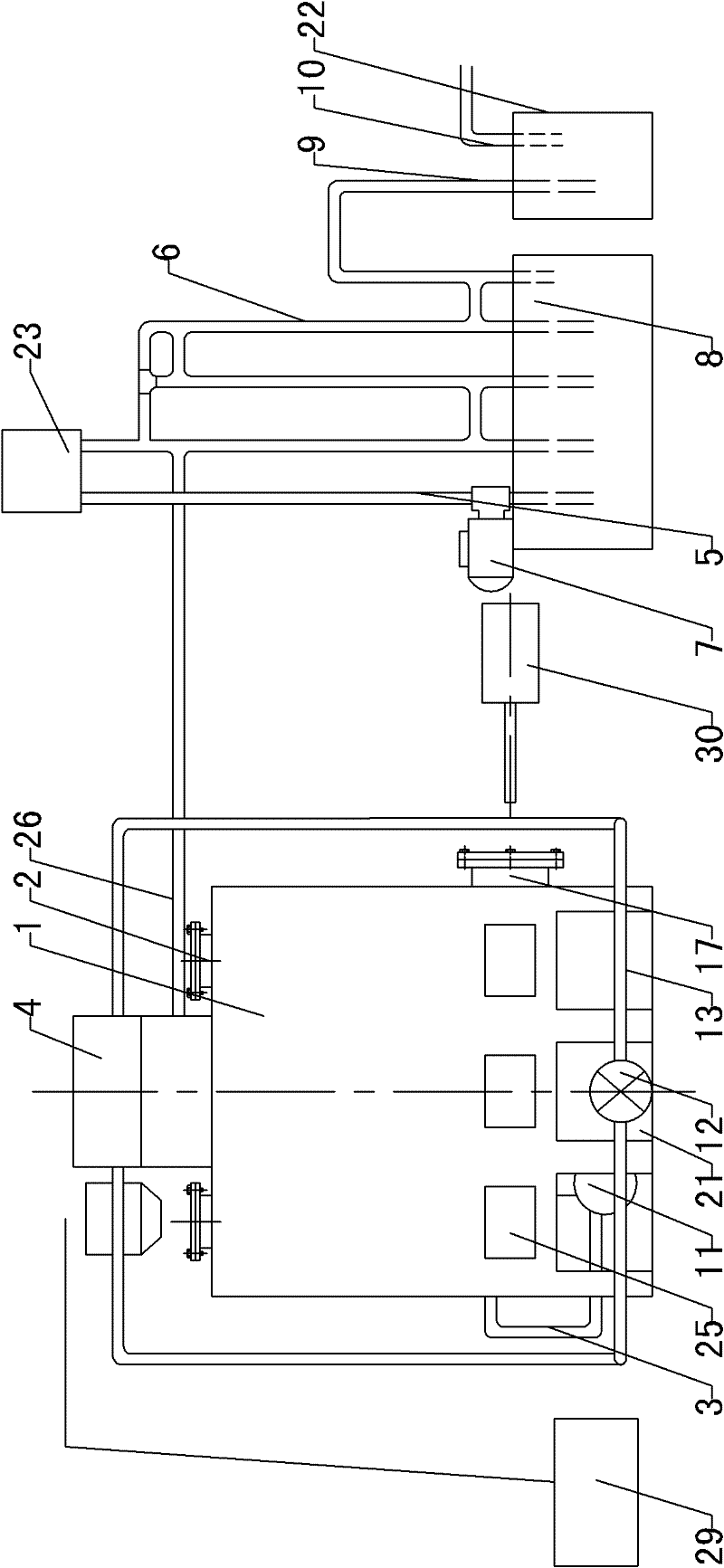

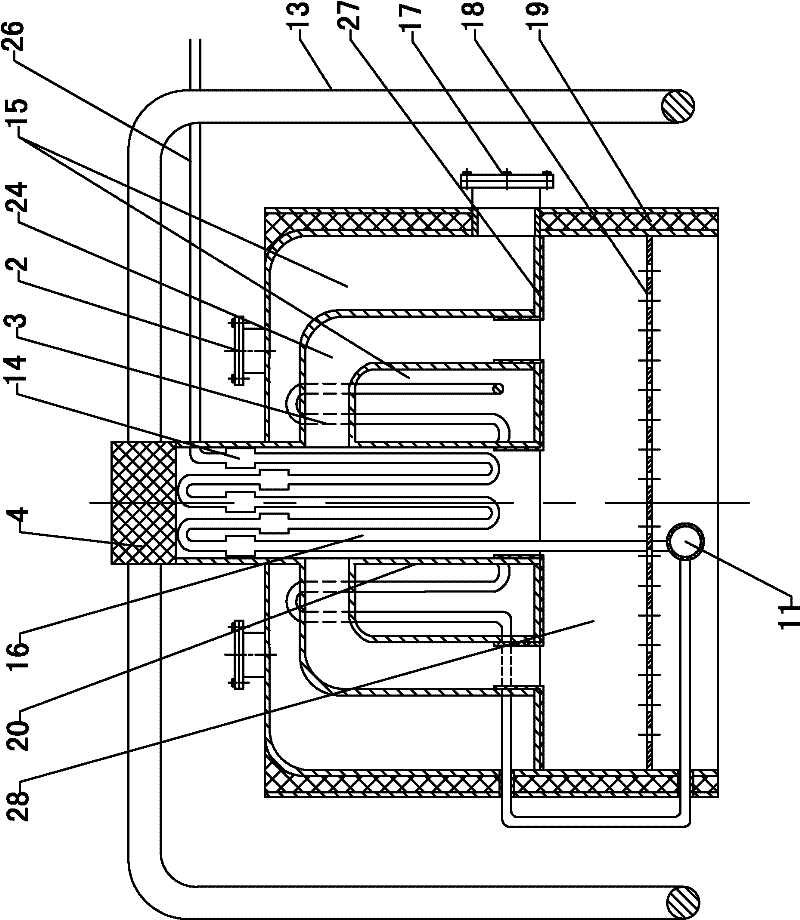

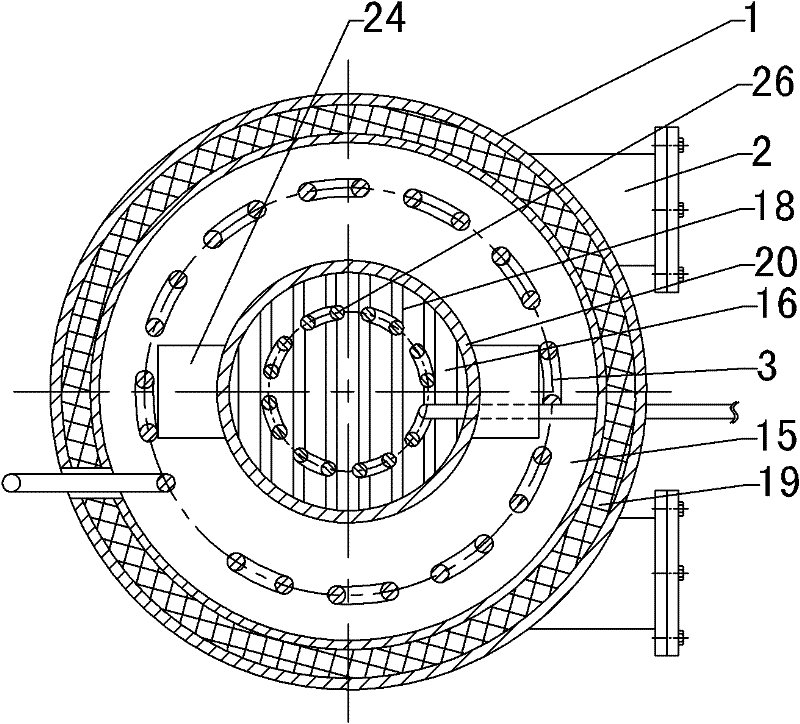

[0024] Refer to attached Figure 1~3 :

[0025] This biomass vehicle engine gas reaction equipment includes a furnace body 1, a water washing cooling device and a dehydration filter device. The outside of the furnace body 1 is provided with an insulating layer 19, and the furnace body 1 is divided into a pyrolysis and carbonization chamber 15 and a main radiation chamber by a furnace inner wall 20. Chamber 16, pyrolysis and retort chamber 15 and main radiation chamber 16 lower part and fire grate 18 form combustion chamber 28, and pyrolysis and retort chamber 15 is provided with sub-radiation chamber 24 connecting main radiation chamber 16 and combustion chamber 28, and main radiation chamber 16 The top is provided with an air preheating device, the top of the pyrolysis and carbonization chamber 15 is provided with a feed port 2, and the lower side is provided with a discharge port 17. Both the feed port 2 and the discharge port 17 are equipped with sealing covers. Feeding de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com