Method for synthesizing blocky magnesium-based nano composite material by self-organized reaction

A technology of nanocomposite materials and eutectic structure, applied in the direction of nanotechnology, can solve the problems of uneven distribution of reinforcement phase, increase of process complexity and cost, difficulty in microstructure control, etc., achieve high interface connection strength and save energy , the effect of uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0036] 1) Preparation conditions and equipment

[0037] The matrix material selected is magnesium powder with a purity of 99.8%, and the metal oxide powder with a purity of 99.0% to 99.9% is selected as the reinforcing phase material. Sintering adopts controllable atmosphere PID intelligent control tube furnace, phase identification adopts X-ray diffractometer (XRD), microstructure observation and analysis adopts environmental electron microscope (SEM; LEO 1450VP) and transmission electron microscope (TEM; Philips CM 120 ), and the hardness was tested using a microhardness tester (Buehler 2103, IL).

[0038] 2) Selection of sintering process

[0039] The sintering temperature is 450-630°C. Select different sintering temperatures according to different material systems, and keep them warm for 30-90 minutes. Then, the samples are cooled or quenched in the furnace. See the examples for specific parameters.

example 1

[0041] Table 1 shows the selected material system and composition ratio:

[0042] Table 1 The ratio of Mg-CuO

[0043]

[0044] The powder is cold-pressed under a pressure of 500 MPa.

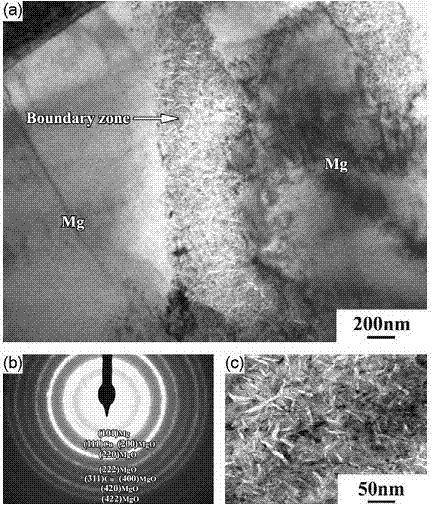

[0045] Under the protection of argon, the green body 1 was kept at 450°C for 90 minutes, and cooled with the furnace. According to the XRD phase identification, the sintered sample contained three phases of Mg, MgO and Cu, and MgO was evenly distributed among the Mg particles. At the interface, the observation and analysis results of the transmission electron microscope show that the MgO exists at the interface in the form of one-dimensional nanowires, ( figure 1 ).

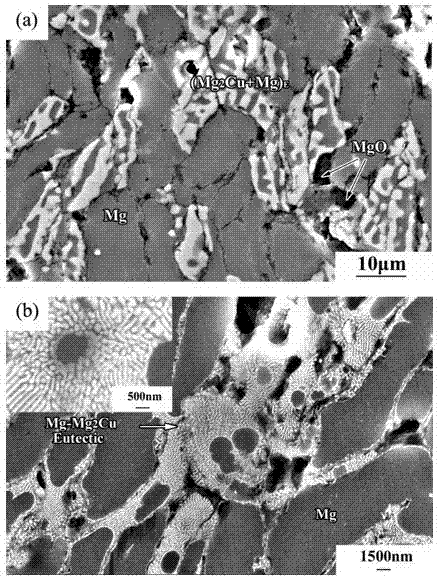

[0046] Green body 2 and green body 3 were kept at 550°C for 60 minutes and then cooled and quenched in the furnace respectively. According to XRD phase analysis, it was found that the two samples after sintering contained Mg, MgO and Mg 2 Three phases of Cu; through scanning electron microscopy, it was found that there were ...

example 2

[0049] Table 2 shows the selected material system and composition ratio:

[0050] Table 2 The ratio of Mg-NiO

[0051]

[0052] The powder was cold-pressed under the pressure of 400MPa and 500MPa respectively for comparison.

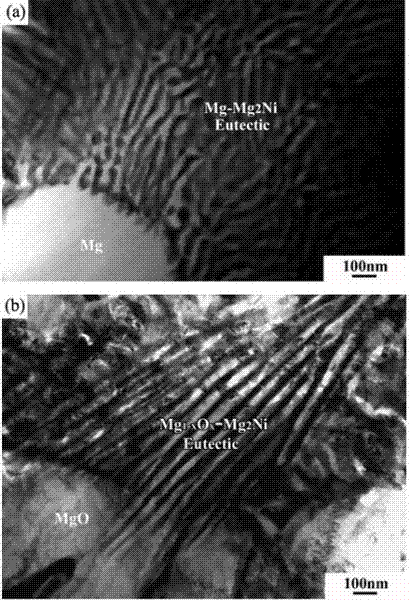

[0053] Under the protection of argon, the green body was kept at 550°C for 60 minutes and then rapidly cooled. XRD phase analysis found that the sintered sample contained Mg, MgO and Mg 2 There are three phases of Ni; through scanning electron microscope observation, it is found that two kinds of nano-eutectic structures with different structures are formed in this sample ( image 3 ), where a) is the nanoeutectic structure formed around Mg particles; b) is the nanoeutectic structure formed around MgO particles.

[0054] There is no difference in microstructure after sintering of green compacts with different molding pressures.

[0055] The various nano-eutectics formed by the reaction not only serve as the reinforcing phase of the matrix material,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com