Method for in-situ growing carbon nanotubes on fiber surfaces

A technology for in-situ growth of carbon nanotubes, which is applied in the fields of carbon fiber, fiber treatment, textiles and papermaking, and can solve the problems of unfavorable large-scale preparation of micro-nano composite fibers and uneven growth of carbon nanotubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

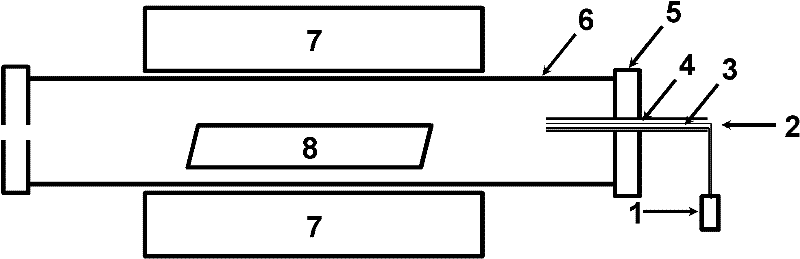

[0019] (1) Cut the carbon fiber fabric to 2cm×2cm and place it in the middle of the reaction furnace. Preparation of reaction solution: 1.75g of ferrocene was dissolved in 15g of toluene solution, and 0.875g of thiophene was added dropwise. Then the mixed solution was ultrasonically dispersed for 5 min.

[0020] (2) Raise the temperature of the horizontal reactor to 700°C at a rate of 10°C / min, inject the reaction solution into a gas flow of 50ml / min argon as a carrier gas at a rate of 10ml / h, and react at a high temperature of 700°C In a furnace, carbon nanotubes grow directly on the surface of carbon fiber fabrics.

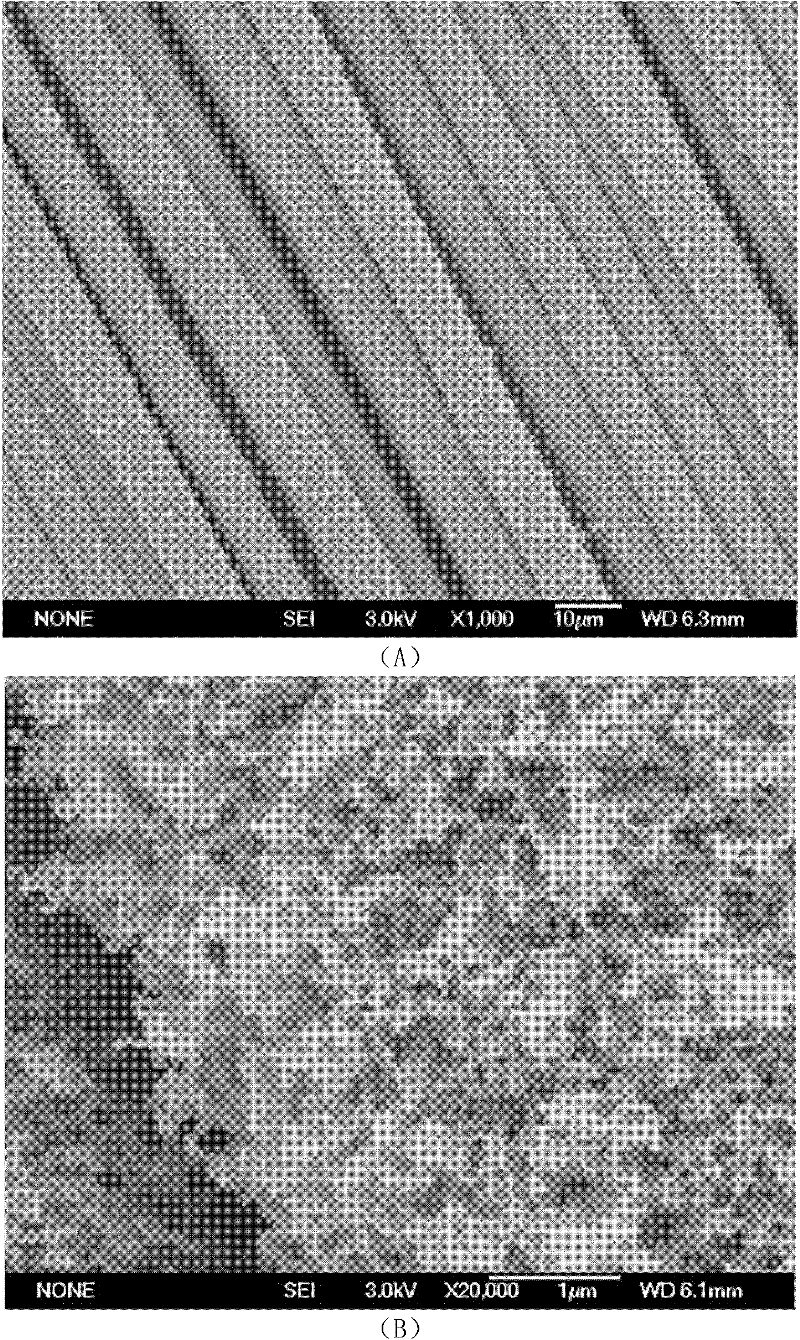

[0021] (3) figure 2 It is a scanning electron microscope picture of the micro-nano composite carbon fiber obtained in Example 1 of the present invention. (A) Carbon fiber fabric coated with carbon nanotubes, and the carbon nanotubes are uniformly dispersed; (B) Carbon nanotubes grown on the surface of carbon fibers.

Embodiment 2

[0023] (1) Cut the glass fiber fabric to 2cm×2cm and place it in the middle of the reaction furnace. Prepare the reaction solution: weigh 0.65g of ferrocene, dissolve it in 11.7g of xylene solution, and add 0.65g of thiophene dropwise. Then the mixed solution was ultrasonically dispersed for 5 min.

[0024] (2) Raise the temperature of the horizontal reaction furnace to 800°C at a rate of 10°C / min, inject the reaction liquid into the airflow of 50ml / min hydrogen as the carrier gas at a rate of 10ml / h, In , carbon nanotubes grow directly on the surface of glass fiber fabrics.

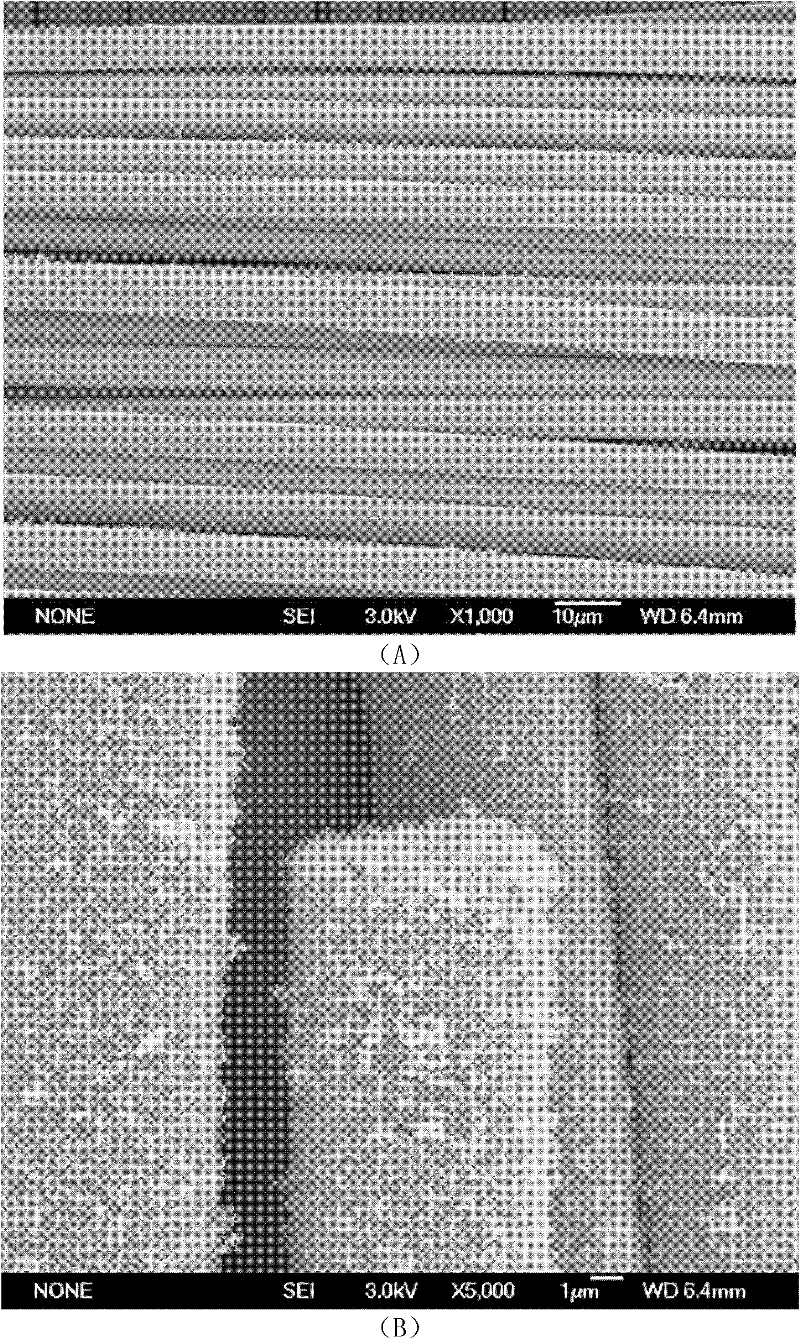

[0025] (3) image 3 It is a scanning electron microscope picture of the micro-nano composite glass fiber obtained in Example 2 of the present invention. (A) Glass fiber fabric coated with carbon nanotubes; (B) CNT layer grown on the glass fiber surface.

Embodiment 3

[0027] (1) Cut the silicon carbide fiber fabric to 2cm×2cm and place it in the middle of the reaction furnace. Prepare the reaction solution: weigh 0.14g of ferrocene, dissolve it in 13.3g of acetone solution, and add 0.56g of thiophene dropwise. Then the mixed solution was ultrasonically dispersed for 5 min.

[0028] (2) Raise the temperature of the horizontal reaction furnace to 900°C at a rate of 10°C / min, inject the reaction solution into the airflow of 100ml / min hydrogen as the carrier gas at a rate of 5ml / h, and heat the reactor at a high temperature of 900°C In , carbon nanotubes grow directly on the surface of silicon carbide fiber fabrics.

[0029] (3) Figure 4 Scanning electron micrograph of the micro-nano composite silicon carbide fiber obtained in Example 3 of the present invention, (A) a silicon carbide fiber fabric covered by carbon nanotubes; (B) a carbon nanotube layer grown on the surface of the silicon carbide fiber

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com