Preparation technology for silicon nano-aperture array photovoltaic material and photovoltaic cell

A technology of photovoltaic cells and photovoltaic materials, which is applied in the fields of circuits, electrical components, and final product manufacturing, and can solve the problems of unstable battery structure and low photoelectric conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

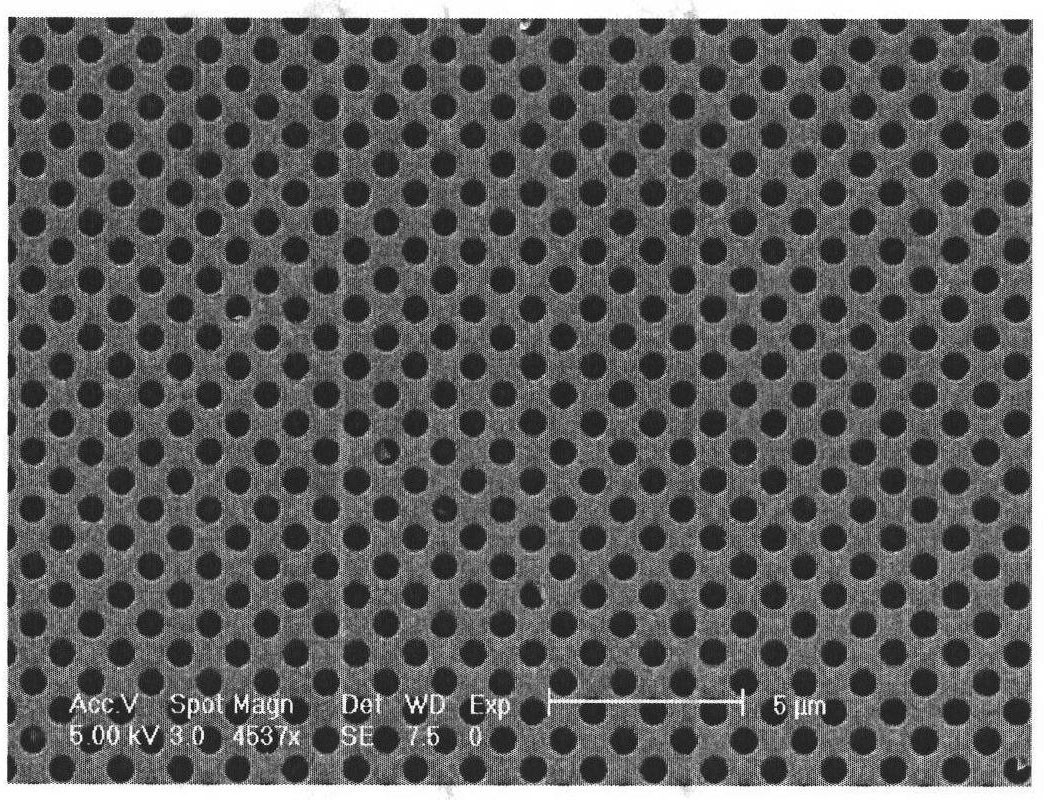

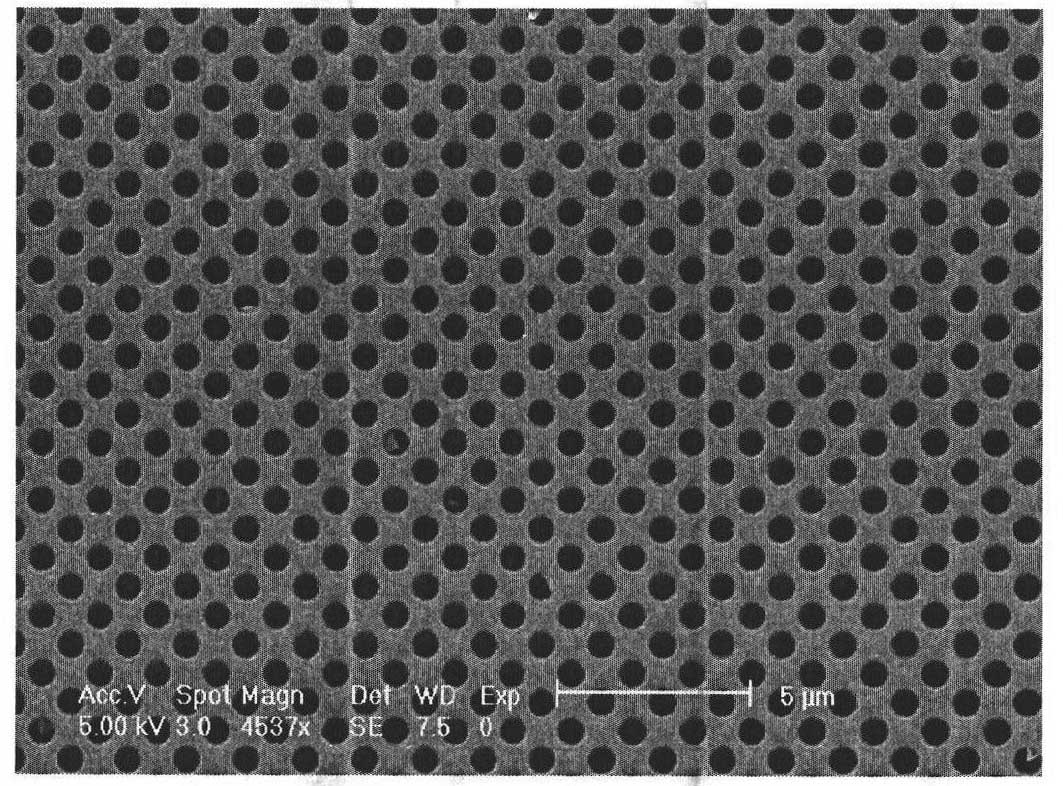

[0021] Using deep ultraviolet lithography technology and high vacuum metal deposition technology to obtain a large area of the same size and periodically distributed silver nanoparticle arrays on the surface of a clean silicon wafer; then immediately immerse the silicon wafer in a HF+H 2 o 2 +H 2 In an airtight container of O etching solution, treat at 25 degrees Celsius for 20 minutes to obtain a silicon nanohole array. The samples were then soaked in concentrated nitric acid solution for at least one hour to remove the silver film on the surface.

specific Embodiment approach 2

[0022] Using deep ultraviolet lithography technology and high-vacuum metal deposition technology to obtain a large area of the same size and periodically distributed gold nanoparticle arrays on the surface of a clean silicon wafer; then immediately immerse the silicon wafer in a HF+H 2 o 2 +H 2 In an airtight container of O etching solution, treat at 25 degrees Celsius for 20 minutes to obtain a silicon nanohole array. The samples were then soaked in aqua regia solution for at least one hour to remove the gold film on the surface.

specific Embodiment approach 3

[0023] Deposit a uniformly distributed silver film on the surface of a clean silicon wafer using high-vacuum metal deposition technology, and then thermally anneal at 200 degrees Celsius under a nitrogen protective atmosphere to form a large-area array of silver nanoparticles with the same size and periodic distribution on the silicon surface; then immediately Immerse the silicon wafer in HF+H 2 o 2 +H 2 In an airtight container of O etching solution, treat at 25 degrees Celsius for 30 minutes to obtain a silicon nanohole array. The samples were then soaked in concentrated nitric acid solution for at least one hour to remove the silver film on the surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com