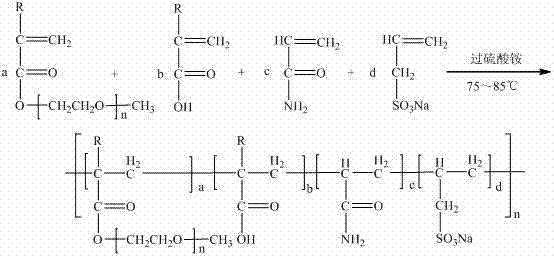

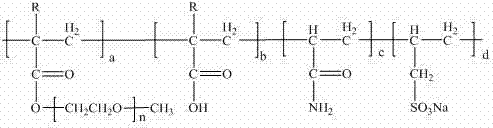

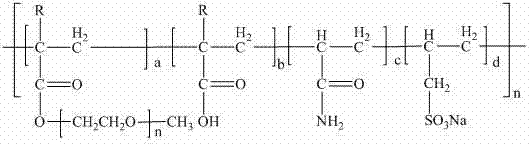

Ultra-high efficiency polycarboxylate water reducer and preparation method thereof

A high-efficiency polycarboxylate and polycarboxylate technology, which is applied in the field of super-efficient polycarboxylate water reducers, can solve problems such as rapid loss of concrete slump, complex mineralization components, and impact on project quality. Improve various performances, high water reduction effect, and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add 20g of MPEG (2000), 8.58g of cyclohexane, 0.96g of catalyst p-toluenesulfonic acid, and 0.0086g of polymerization inhibitor hydroquinone into a four-necked flask with a water separator. After heating to 80°C, add 1.44 g acrylic acid, heat up to 130°C for 8 hours, after the reaction, pour the product into a small beaker filled with n-hexane, precipitate in an ice-water bath, and then place it in a vacuum oven at 30°C for 24 hours to obtain esterified Monomer MPEGAA.

Embodiment 2

[0023] Add 20g MPEG (2000), 8.72g cyclohexane, 0.98g catalyst p-toluenesulfonic acid, 0.0108g polymerization inhibitor hydroquinone into a four-necked flask with water separator, after heating to 80°C, add 1.80 g of acrylic acid, heated up to 130°C for 8 hours, after the reaction, pour the product into a small beaker filled with n-hexane, precipitate it in an ice-water bath, and then place it in a vacuum oven at 30°C for 24 hours to obtain esterified Monomer MPEGAA.

Embodiment 3

[0025] Add 20g of MPEG (2000), 9.01g of cyclohexane, 1.013g of catalyst p-toluenesulfonic acid, and 0.0151g of polymerization inhibitor hydroquinone into a four-necked flask with a water separator. After heating to 80°C, add 2.52 g of acrylic acid, heated up to 130°C for 8 hours, after the reaction, pour the product into a small beaker filled with n-hexane, precipitate it in an ice-water bath, and then place it in a vacuum oven at 30°C for 24 hours to obtain esterified Monomer MPEGAA.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com