Diamine, polymer obtained from reaction with the presence of the diamine, liquid crystal aligning agent containing the polymer, liquid crystal alignment layer and liquid crystal display device

A technology of diamines and mixtures, which can be applied to compounds of elements of Group 4/14 of the periodic table, liquid crystal materials, steroids, etc., and can solve problems such as ion density reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0574] Hereinafter, the present invention is illustrated by examples. In addition, the compounds used in the examples are shown below.

[0575]

[0576] Anhydride (1): pyromellitic dianhydride

[0577] Anhydride (19): 1,2,3,4-cyclobutanetetracarboxylic dianhydride

[0578]

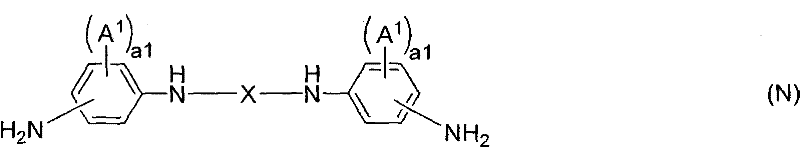

[0579] Diamine (N-1): bis-4-(N,N'-(4-aminophenyl)aminophenyl)methane

[0580] Diamine (N-3): 1,3-bis-4-(N,N'-(4-aminophenyl)aminophenyl)propane

[0581] Diamine (V-1): 4,4'-diaminodiphenylmethane

[0582] Diamine (V-7): 4,4'-diamino-1,2-diphenylethane

[0583] Diamine (XII-2-1): 1,1-bis[4-(4-aminophenyl)methylphenyl]-4-n-heptylcyclohexane

[0584] Diamine (XII-4-1): 1,1-bis[4-(4-aminophenoxy)phenyl-4-(trans-4-n-pentylcyclohexyl)cyclohexane

[0585]

[0586] NMP: N-methyl-2-pyrrolidone

[0587] BC: Butyl cellosolve (ethylene glycol monobutyl ether)

[0588]

[0589] Compound: bis[4-(allylbicyclo[2.2.1]hept-5-ene-2,3-dicarboxyimide)phenyl]methane: BANI-M

[0590] Compound: 4,4'-methylene bis...

Synthetic example 1

[0604] 3.885 g of compound (N-1) and 40.0 g of dehydrated NMP were placed in a 100 mL four-neck flask equipped with a thermometer, a stirrer, a raw material inlet, and a nitrogen gas inlet, and stirred and dissolved under a dry nitrogen stream. Next, 1.114 g of the compound (1), 1.001 g of the compound (19), and 40.0 g of dehydrated NMP were put in, and reacted at room temperature for 15 hours. BC 14.0g was added to the obtained solution, and the polyamic-acid solution whose solid content concentration was 6 wt% was obtained. This polyamic acid is described as PA1. The weight average molecular weight of PA1 is 80200.

[0605]The weight-average molecular weight of the polyamic acid is obtained by diluting the obtained polyamic acid with a phosphoric acid-DMF mixed solution (phosphoric acid / DMF=0.6 / 100: weight ratio) so that the polyamic acid concentration is about 2 wt%. , using a 2695 separation module·2414 differential refractometer (manufactured by Waters), using the above...

example 1

[0611]

[0612] The polyamic acid solution (PA1) that is 6wt% by the solid content concentration that is synthesized in the synthetic example 1, is diluted to the solid content concentration by adding the mixed solvent of NMP / BC=4 / 1 (weight ratio) and is 4wt%, is made Liquid crystal alignment agent. Using the obtained liquid crystal alignment agent, a liquid crystal display element was produced as follows.

[0613]

[0614] On two glass substrates with ITO electrodes, a liquid crystal alignment agent was applied using a spinner to form a film with a film thickness of 70 nm. After coating, heat drying was performed at 80° C. for about 1 minute, and then heat treatment was performed at 210° C. for 15 minutes to form a liquid crystal alignment film. Next, an alignment treatment is performed by rubbing the surface of the substrate on which the liquid crystal alignment film is formed with a rubbing device. Thereafter, the liquid crystal alignment film was ultrasonically clean...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com