Thermosetting acrylic resin for electrogilding oil and preparation method thereof

An acrylic resin, electroplating gold oil technology, applied in the direction of coating, can solve the problems of high resin compatibility requirements, poor miscibility and comprehensive performance, narrow application surface of electroplating gold oil, etc. The effect of poor comprehensive performance, excellent low temperature bridging and excellent salt spray resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In this implementation, the preparation method of thermosetting acrylic resin for electroplating gold oil comprises the steps:

[0024] 1. Preparation of unsaturated polyester intermediate:

[0025] 1) See Table 1 for the ratio of raw materials for preparing unsaturated polyester intermediates:

[0026] Table 1 prepares unsaturated polyester intermediate raw material ratio

[0027] raw material name

Mass percentage / %

20

10

1

6

Isophthalic anhydride

27

[0028] p-methoxyphenol

0.03

30

5.97

[0029] 2) The steps for preparing the unsaturated polyester intermediate are as follows:

[0030] First put the monomer and antioxidant in the formula amount into the reaction kettle, pass N 2 After heating up to 150°C, take 3 hours to raise the temperature to 180°C, then ...

Embodiment 2

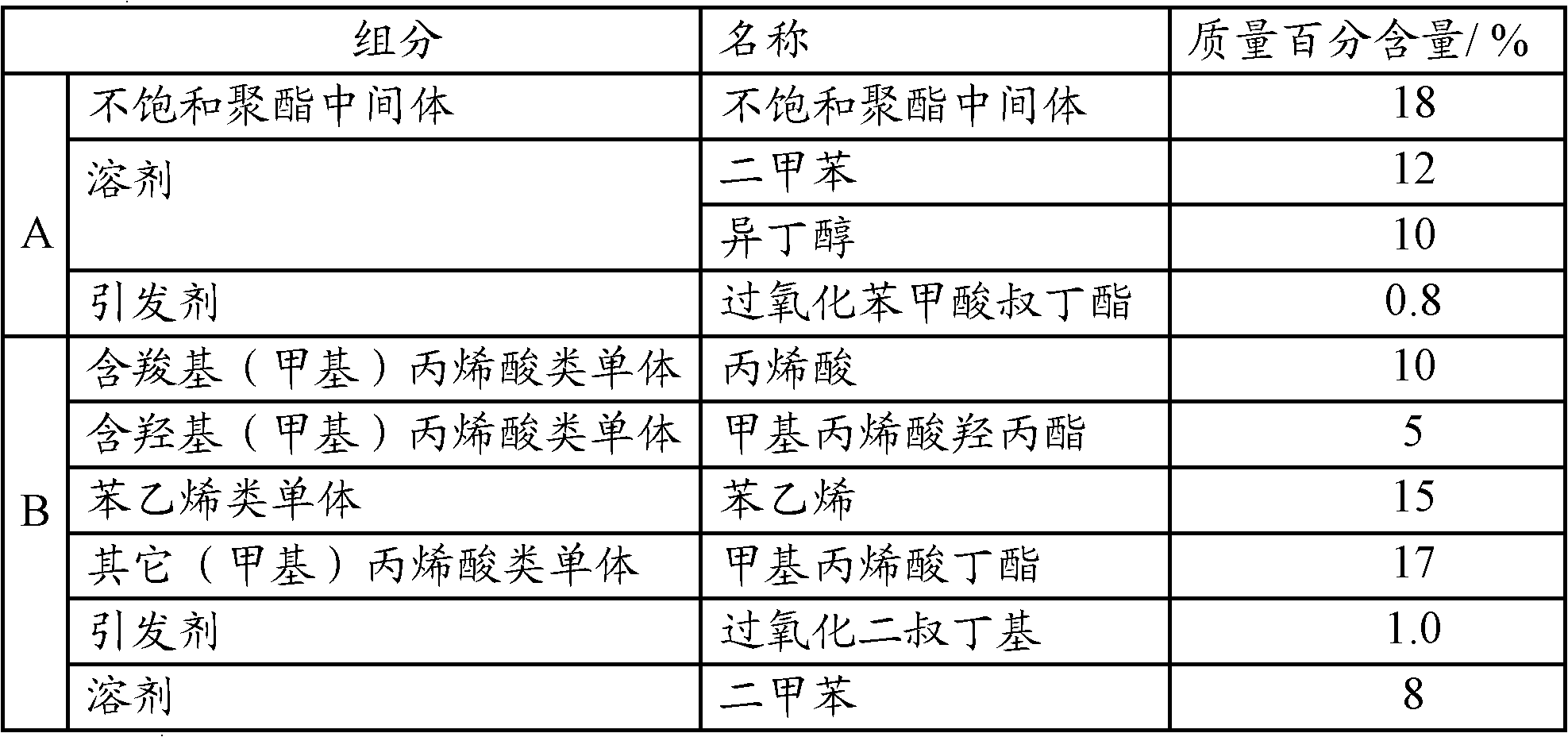

[0040] In this implementation, the preparation method of thermosetting acrylic resin for electroplating gold oil comprises the steps:

[0041] 1. Preparation of unsaturated polyester intermediate

[0042] 1) See Table 3 for the ratio of raw materials for preparing unsaturated polyester intermediates:

[0043] Table 3 prepares unsaturated polyester intermediate raw material ratio

[0044] raw material name

Mass percentage / %

18

12

1

6

Isophthalic anhydride

27

p-methoxyphenol

0.04

29.06

6

[0045] 2) The specific preparation steps are as follows:

[0046] First put the monomer and antioxidant in the formula amount into the reaction kettle, pass N 2 After heating up to 150°C, heat up to 180°C in 3 hours, then heat up to 220°C in 2 hours, keep warm until the acid value is 15mgKOH / ...

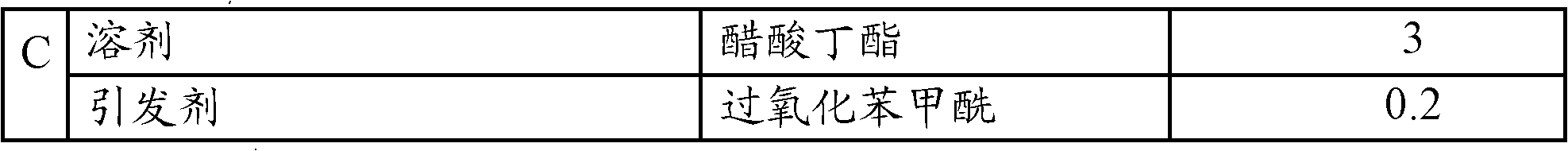

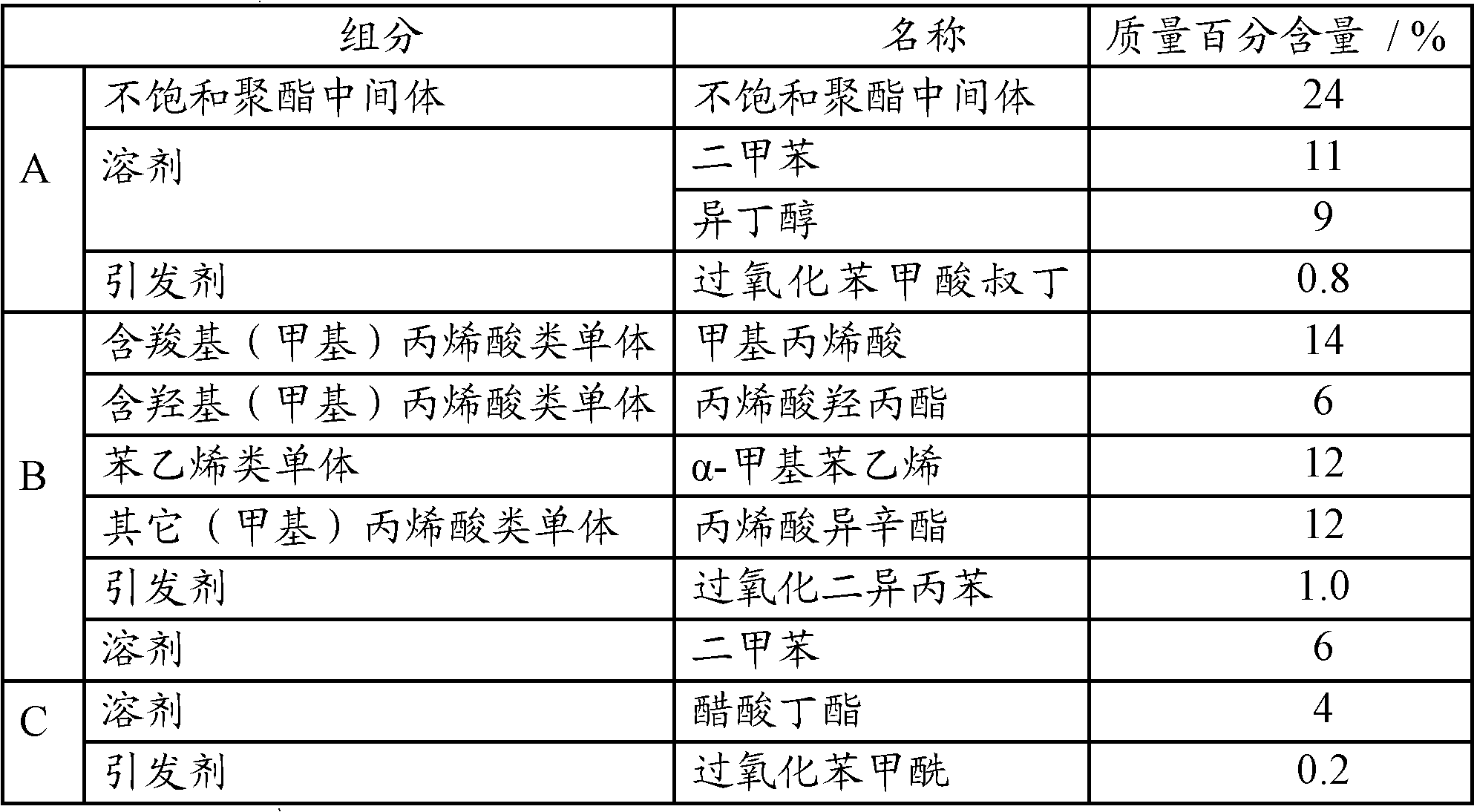

Embodiment 3

[0054] In this implementation, the preparation method of thermosetting acrylic resin for electroplating gold oil comprises the steps:

[0055] 1. Preparation of unsaturated polyester intermediate

[0056] 1) See Table 5 for the ratio of raw materials for preparing unsaturated polyester intermediates in this step:

[0057] Table 5 prepares unsaturated polyester intermediate raw material ratio

[0058] raw material name

Mass percentage / %

19

14

3

4

Isophthalic anhydride

28

p-methoxyphenol

0.03

26

5.97

[0059] 2) The preparation process is as follows:

[0060] First put the monomer and antioxidant in the formula amount into the reaction kettle, pass N 2After heating up to 150°C, take 3 hours to raise the temperature to 180°C, then take 2 hours to raise the temperature to 220°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com