Colloid electrolyte for lead-acid battery and preparation method thereof

A technology of colloidal electrolyte and lead-acid battery, applied in the direction of lead-acid battery, lead-acid battery construction, final product manufacturing, etc., can solve the problem of increasing the corrosion resistance of lead and its alloys, reducing battery capacity, and poor low-temperature performance of the battery ( reduce problems such as increasing charge acceptance, inhibit hydrogen evolution and oxygen evolution reaction, and make the compounding method simple and easy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

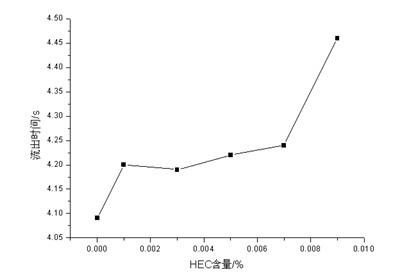

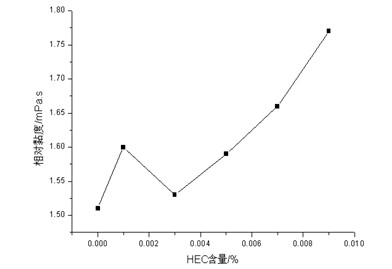

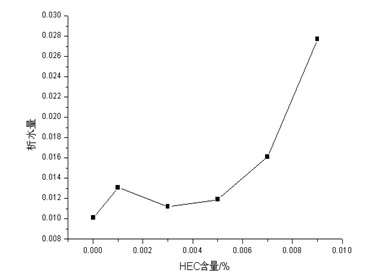

[0043] ①Preparation of 0.05% hydroxyethyl cellulose aqueous solution

[0044] Add a certain amount of hydroxyethyl cellulose powder to a dispersing bucket filled with a certain volume of deionized water, and stir at a low speed while adding. Pour into a volumetric flask.

[0045] ② Prepare a colloidal electrolyte containing 0.001% HEC aqueous solution;

[0046] A silica sol colloidal electrolyte containing HEC was prepared. The preparation method is as follows, take 260 mL of sulfuric acid solution with a mass fraction of 41.5%, add 50 g of silica sol with a mass fraction of 40% silica (produced by Shenzhen Huadao Industrial Co., Ltd.) under stirring at 300 r / min, and then add 8.2 mL of HEC After the material is added, the above system is dispersed at 1500 r / min (dispersion time is 30 minutes). In the obtained colloidal electrolyte, the content of hydroxyethyl cellulose is 0.001% (w / w), the net content of silica is 5% (w / w), and the content of sulfuric acid is 1.28 g / mL.

...

Embodiment 2

[0049] ①Preparation of 0.05% hydroxyethyl cellulose aqueous solution

[0050] Add a certain amount of hydroxyethyl cellulose powder to a dispersing bucket filled with a certain volume of deionized water, and stir at a low speed while adding. Pour into a volumetric flask.

[0051] ② Prepare a colloidal electrolyte containing 0.003% HEC aqueous solution;

[0052] The preparation method is as follows: take 244 mL of sulfuric acid solution with a mass fraction of 43.6%, add 50 g of silica sol with a mass fraction of 40% silica under stirring at 300 r / min, and then add 24.67 mL of HEC aqueous solution. min to disperse the above system (dispersion time 30 minutes). In the obtained colloidal electrolyte, the content of hydroxyethyl cellulose is 0.003% (w / w), the net content of silica is 5% (w / w), and the content of sulfuric acid is 1.28 g / mL.

[0053] ③The fluidity and viscosity test were carried out immediately after the preparation of the colloidal electrolyte; the electrochemic...

Embodiment 3

[0055] ①Preparation of 0.05% hydroxyethyl cellulose aqueous solution

[0056] Add a certain amount of hydroxyethyl cellulose powder to a dispersing bucket filled with a certain volume of deionized water, and stir at a low speed while adding. Pour into a volumetric flask.

[0057] ② Prepare a colloidal electrolyte containing 0.005% HEC aqueous solution;

[0058] A silica sol colloidal electrolyte containing HEC was prepared. The preparation method is as follows: take 229 mL of sulfuric acid solution with a mass fraction of 45.8%, add 50 g of silica sol with a mass fraction of silica of 40% under stirring at 300 r / min, and then add 41 mL of HEC aqueous solution. After the material is added, 1500 r / min The above system was dispersed (dispersion time 30 minutes). In the obtained colloidal electrolyte, the content of hydroxyethyl cellulose is 0.005% (w / w), the net content of silica is 5% (w / w), and the content of sulfuric acid is 1.28 g / mL.

[0059] ③The fluidity and viscosity ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com