Cefpiramide sodium micro-spheres and preparing method thereof

A technology of cefpiramide sodium and microspheres, which is applied in the field of medicine, can solve the problems of insufficient drug sensitivity, low drug concentration, and short action time, and achieve the effects of short biological half-life, reduced damage, and increased compliance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

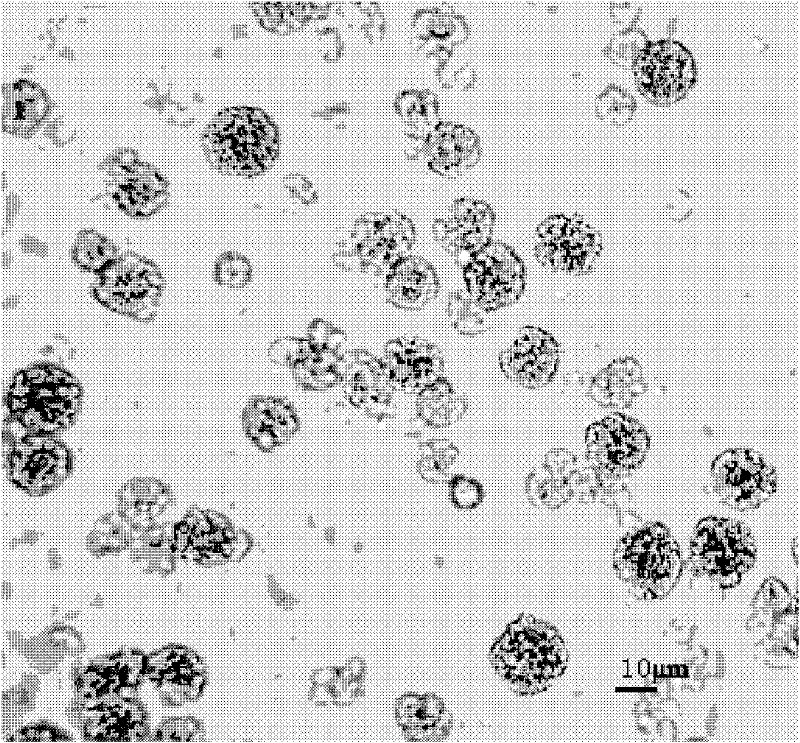

[0029] Embodiment 1: the preparation of cefpiramide sodium microspheres

[0030] Dissolve 10 mg of cefpiramide sodium in 3 ml of 30 mg / ml carboxymethyl chitosan aqueous solution, and ultrasonically dissolve it to form a water phase; take 40 ml of liquid paraffin, add 4.0 g of span-80 to it, and prepare 100 mg / ml span -80 liquid paraffin solution to form the organic phase. Under magnetic stirring, the drug-containing carboxymethyl chitosan solution was added dropwise to the liquid paraffin containing span-80, and after the dropwise addition was completed, the dispersion was continued for 30 minutes. Add 1ml of glutaraldehyde to cross-link and solidify at about 30 minutes, and observe the morphology of the microspheres under an optical microscope. The morphology of the microspheres was observed after stirring for 3 h with an electromagnetic stirrer at 1500 rpm. The microspheres are collected by suction filtration, washed with petroleum ether and then with isopropanol, filtered...

Embodiment 2

[0031] Embodiment 2: the preparation of cefpiramide sodium microspheres

[0032]Dissolve 10 mg of cefpiramide sodium in 3 ml of 30 mg / ml carboxymethyl chitosan aqueous solution, and ultrasonically dissolve it to form a water phase; take 25 ml of liquid paraffin, add 1.25 g of span-80 to it, and prepare a 50 mg / ml span -80 liquid paraffin solution to form the organic phase. Under magnetic stirring, the drug-containing carboxymethyl chitosan solution was added dropwise to the liquid paraffin containing span-80, and after the dropwise addition was completed, the dispersion was continued for 30 minutes. Add 1ml of glutaraldehyde to cross-link and solidify at about 30 minutes, and observe the morphology of the microspheres under an optical microscope. The morphology of the microspheres was observed after stirring for 3 h with an electromagnetic stirrer at 1500 rpm. The microspheres are collected by suction filtration, washed with petroleum ether and then with isopropanol, filtere...

Embodiment 3

[0033] Embodiment 3: the preparation of cefpiramide sodium microspheres

[0034] Dissolve 10 mg of cefpiramide sodium in 3 ml of 30 mg / ml carboxymethyl chitosan aqueous solution, and ultrasonically dissolve it to form an aqueous phase; take 40 ml of liquid paraffin, add 2.0 g of span-80 to it, and prepare a 50 mg / ml span -80 liquid paraffin solution to form the organic phase. Under magnetic stirring, the drug-containing carboxymethyl chitosan solution was added dropwise to the liquid paraffin containing span-80, and after the dropwise addition was completed, the dispersion was continued for 30 minutes. Add 1ml of glutaraldehyde to cross-link and solidify at about 30 minutes, and observe the morphology of the microspheres under an optical microscope. The morphology of the microspheres was observed after stirring for 2 h with an electromagnetic stirrer at 1000 rpm. The microspheres are collected by suction filtration, washed with petroleum ether and then with isopropanol, filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com