Method and device for treating nitrochlorobenzene waste gas

A technology of nitrochlorobenzene and exhaust gas, which is applied in the direction of separation methods, chemical instruments and methods, steam condensation, etc., can solve the problems of secondary pollution, easy solidification of nitrochlorobenzene, pollution, etc., and achieve the effect of high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solution of the utility model is further specifically described below through the embodiments and in conjunction with the accompanying drawings.

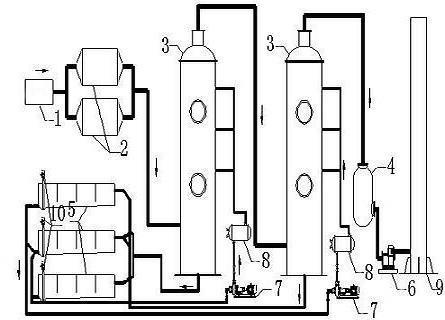

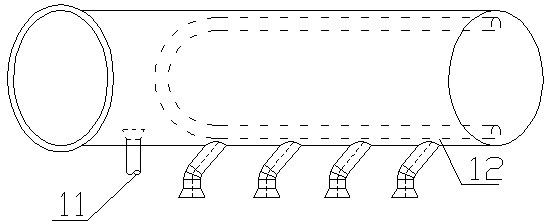

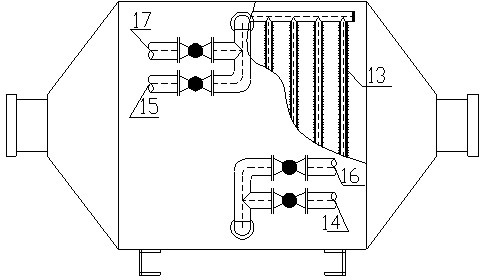

[0035] Such as figure 1 The shown nitrochlorobenzene waste gas treatment device includes a gas collection system 1 , a cooling system 2 , a spray purification system 3 , a solid-liquid separation system, and an air induction system 6 . The gas collection system 1 is composed of multiple sets of suction hoods, and the exhaust gas of different types of materials is sent here separately through the exhaust pipe to prevent the exhaust gas from crossing, and to pre-cool the exhaust gas while collecting. Duct such as figure 2 As shown, it is equipped with a steam nozzle 11, and a steam pipe 12 is arranged in the air pipe, which is used for dredging the chemical material after the material solidifies and blocks the pipeline; the cooling system 2 is composed of two sets of finned condensers, one for standby and one fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com