Method for preparing high-strength carbon nano tube supported platinum catalyst

A carbon nanotube and platinum catalyst technology is applied in the field of preparation of carbon nanotube-supported platinum hydrogenation catalyst, which can solve the problems of loose carbon tube structure, industrial application limitation, high pressure crushing strength of Pt/CNT catalyst, etc., and achieve high hydrogenation The effect of conversion rate, good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2

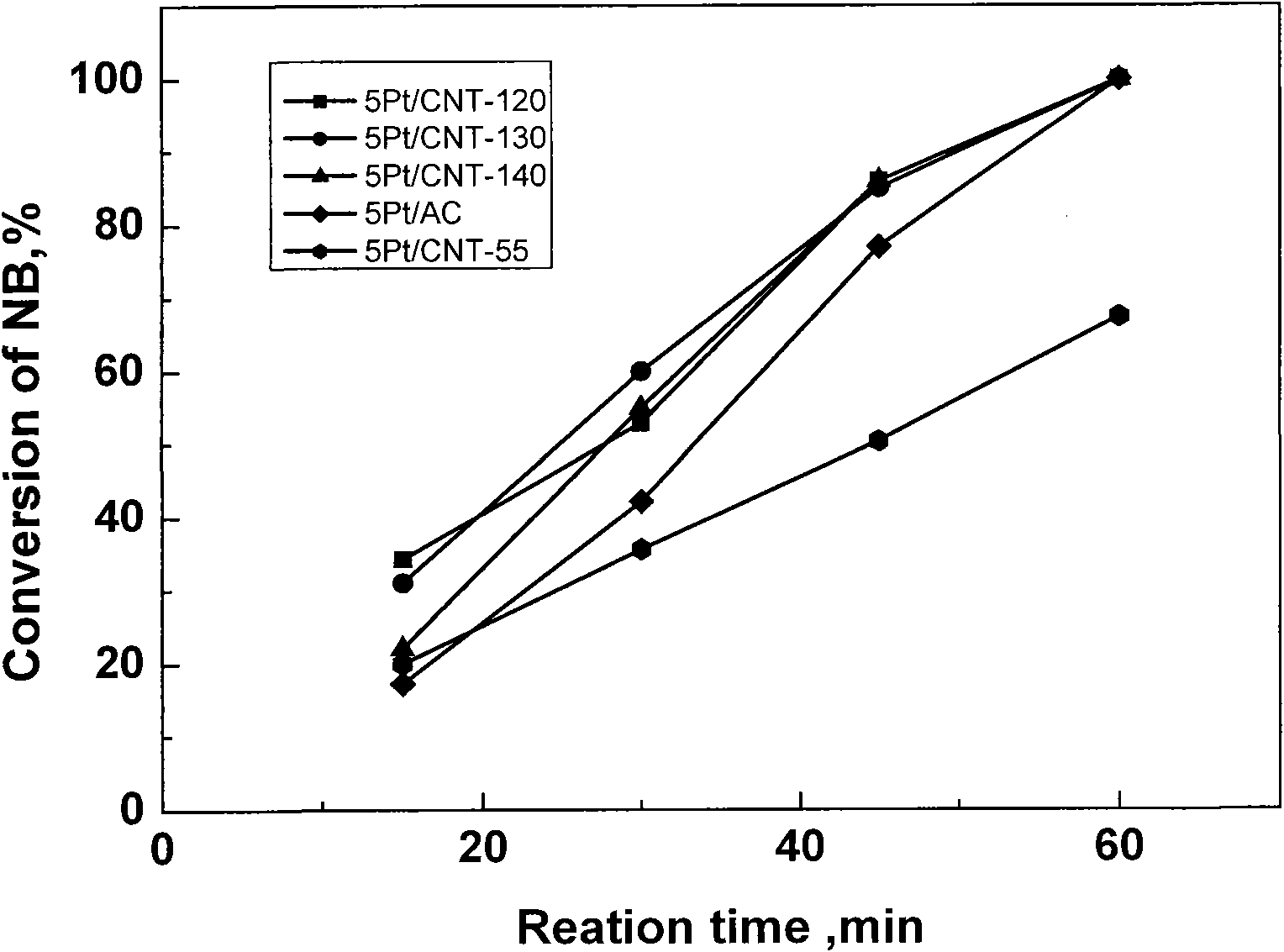

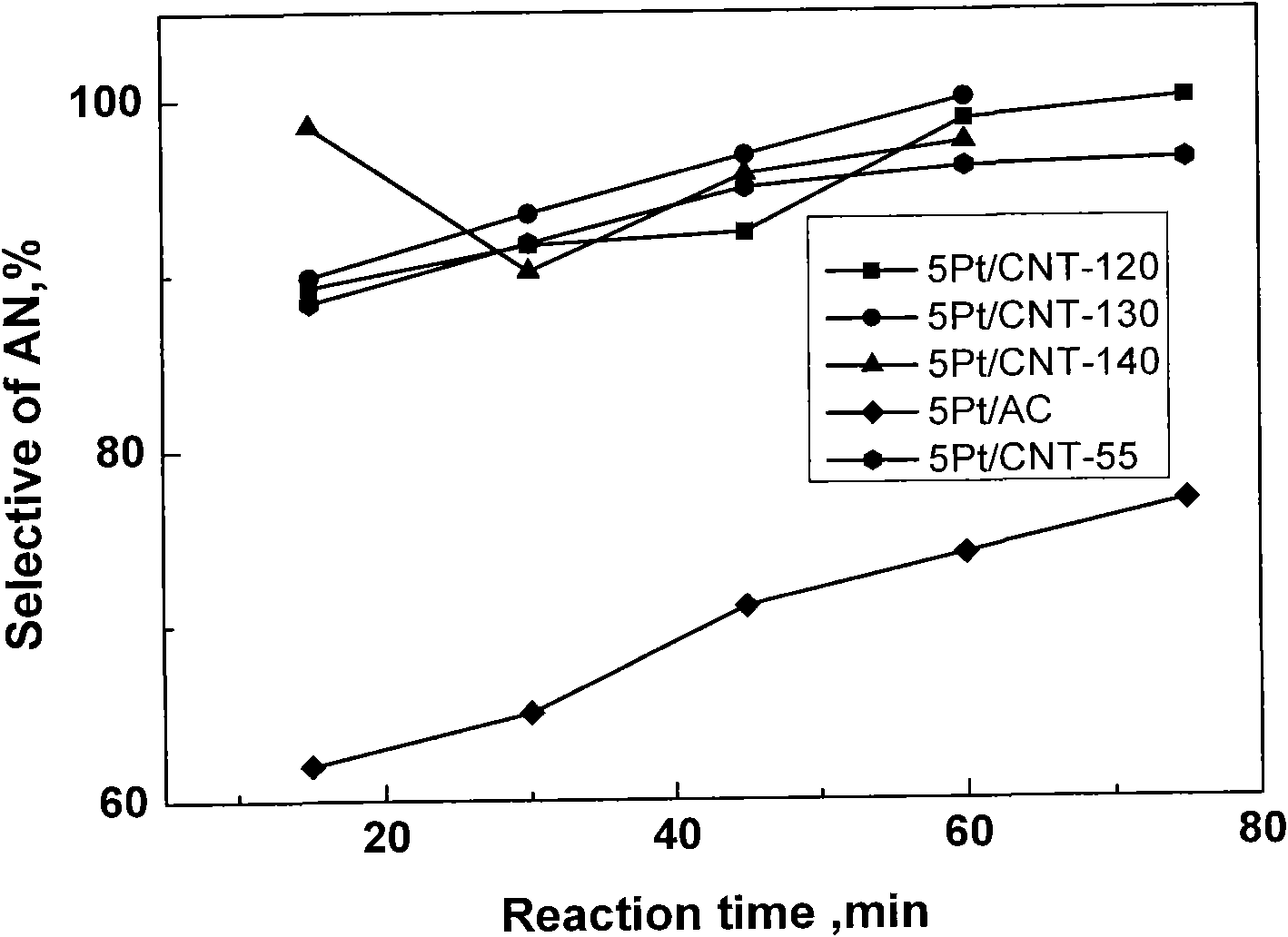

[0025] The preparation of embodiment 1-2 carbon nanotube supported platinum (Pt / CNT) catalyst

[0026] 4g primary carbon nanotubes are placed in the mixed acid of 200ml concentrated sulfuric acid and concentrated nitric acid (volume ratio H 2 SO 4 : HNO 3 = 3:1), condensed and refluxed in an oil bath at 120°C and 130°C under mechanical stirring for 1 hour, cooled to room temperature, filtered, washed with deionized water until neutral, and then dried in a clean oven at 110°C for 24 hours . They are denoted as CNT-120 and CNT-130, respectively.

[0027] Weigh 0.24g of the treated carbon nanotubes, add an appropriate amount of water, and ultrasonically treat for 10 minutes to form a carbon slurry, then pipette 0.8ml of chloroplatinic acid solution with a concentration of 0.0772mol / L into the carbon slurry, and adjust to neutral with ammonia water , sonicate evenly, after soaking for 24 hours, add an appropriate amount of ethanol and evaporate the solution to dryness in a rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com