Coloring composition, color filter and color liquid crystal display element

A technology of coloring composition and colorant, which is applied in the direction of optical components, instruments, optical filters, etc., can solve the problems of pigment micronization, etc., and achieve the effect of excellent alkali developability and excellent storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0185] Hereinafter, an Example is given and the embodiment of this invention is demonstrated more concretely. However, the present invention is not limited to the following examples.

[0186]

Synthetic example 1

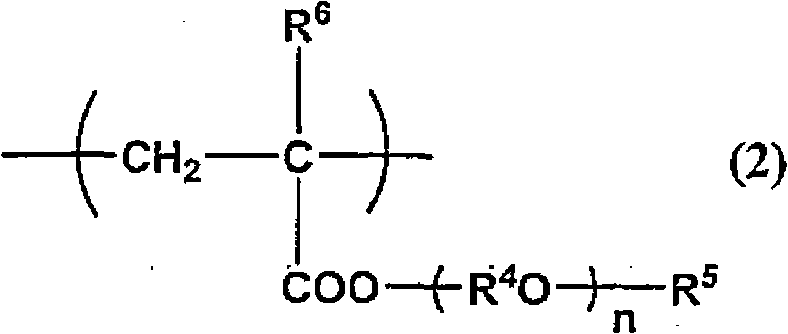

[0188] In a flask equipped with a stirring bar, 0.6 g of methoxypolyethylene glycol monomethacrylate (PME-200 manufactured by NOF Corporation) (hereinafter referred to as "PME-200"), n-butyl methacrylate (hereinafter referred to as "nBMA") 12.9 g, methyl methacrylate (hereinafter referred to as "MMA") 10.5 g, 2,2'-azobisisobutyronitrile (hereinafter referred to as "AIBN") 323 mg, and pyrazole - 833 mg of cyano(dimethyl)methyl 1-dithiocarboxylate (pilazo-1-dithiocarboxylate) was dissolved in 30 mL of toluene, and nitrogen gas was bubbled for 30 minutes. Thereafter, the reaction solution was stirred slowly to raise the temperature of the reaction solution to 57° C., and the temperature was maintained for 34 hours to perform living radical polymerization.

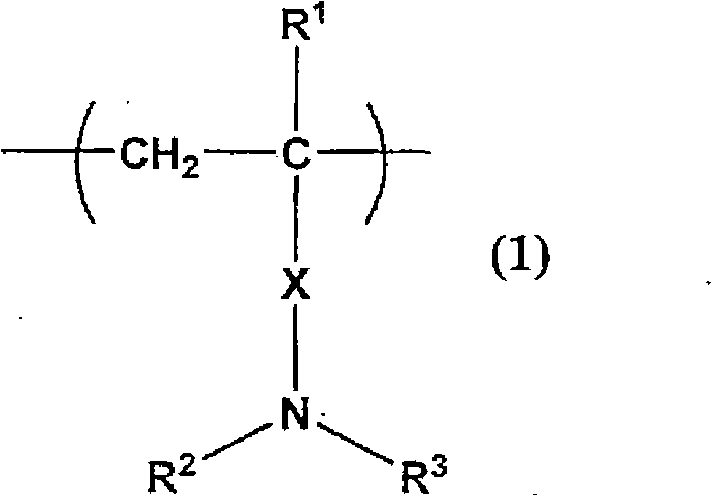

[0189] Next, 211 mg of AIBN and 4.1 g of dimethylaminoethyl methacrylate (hereinafter referred to as "DAMA") were dissolved in 20 mL of toluene, nitrogen replacement was performed for 30 minutes, and the nitrogen replacement s...

Synthetic example 2

[0191] In a flask equipped with a stirring bar, 1.4 g of PME-200, 10.6 g of nBMA, 2.8 g of 2-ethylhexyl methacrylate (hereinafter referred to as "EHMA"), 7.0 g of MMA, 295 mg of AIBN and 726 mg of pyrazole-1-dithiocarboxylate cyano(dimethyl)methyl ester were dissolved in 30 mL of toluene and nitrogen sparging was performed for 30 minutes. Thereafter, the reaction solution was stirred slowly to raise the temperature of the reaction solution to 60° C., and the temperature was maintained for 24 hours to perform living radical polymerization.

[0192] Next, 352 mg of AIBN and 6.2 g of DAMA were dissolved in 20 mL of toluene, nitrogen replacement was performed for 30 minutes, the nitrogen replacement solution was added to the reaction solution, and living radical polymerization was performed at 60° C. for 24 hours. Thereafter, the solvent was substituted with propylene glycol monomethyl ether acetate by concentration under reduced pressure so that the non-volatile content was 40% b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| amine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com