Resin composition, resin sheet, multilayered printed circuit board, and semiconductor device

A technology of resin composition and compound, applied in the direction of synthetic resin layered products, printed circuit, printed circuit, etc., can solve the problem of long processing time and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

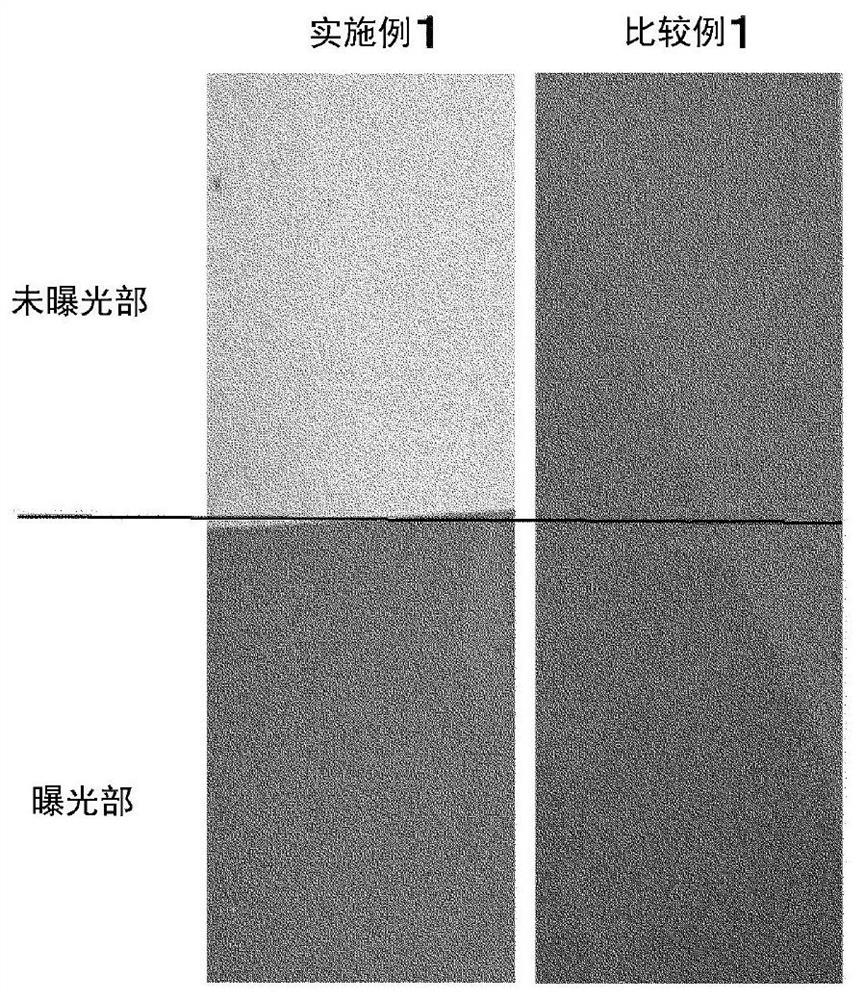

Embodiment 1

[0326] (Production of resin composition and resin sheet)

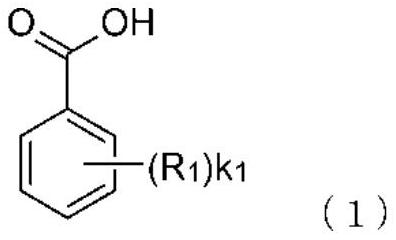

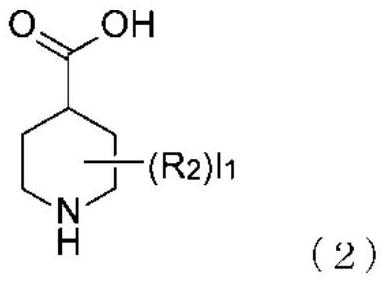

[0327] With respect to 100 parts by mass of BMI-689 (trade name) as the maleimide compound (A), 20 parts by mass of 4-aminobenzoic acid as the carboxylic acid-containing compound (B), and 20 parts by mass as the photocuring initiator (C ), 6 parts by mass of bis(2,4,6-trimethylbenzoyl)-phenylphosphine oxide (Omnirad (registered trademark) 819 (trade name)), mixed with 84 parts by mass of methyl ethyl ketone as an organic solvent, and ultrasonically The homogenizer stirred to obtain a varnish (solution of a resin composition). Using an automatic coating device (PI-1210, manufactured by TESTER SANGYO CO., LTD.), this varnish was applied to a PET film (Unipeel (registered trademark) TR1-38 (trade name) manufactured by Unitika Ltd.) with a thickness of 38 μm. , and heat-dried at 90° C. for 5 minutes to obtain a resin sheet having a PET film as a support and a resin layer having a thickness of 30 μm.

[0328] (Fabrication...

Embodiment 2

[0335] As a carboxylic acid-containing compound (B), except having used 20 mass parts of salicylic acids instead of 20 mass parts of 4-aminobenzoic acids, it carried out similarly to Example 1, and obtained the varnish and resin sheet. Moreover, using the resin sheet, it carried out similarly to Example 1, and obtained the resin for evaluation, and the laminated body for evaluation.

Embodiment 3

[0337] As the maleimide compound (A), instead of 100 parts by mass of BMI-689 (trade name), 100 parts by mass of BMI-1000P (trade name) was used; as the carboxylic acid-containing compound (B), instead of 4-aminobenzoic acid 20 mass parts, use 0.02 mass parts of 4-aminobenzoic acid; As photocuring initiator (C), replace Omnirad (registered trademark) 819 (trade name)) 6 mass parts, use Omnirad (registered trademark) 819 (trade name) ) 5 parts by mass, and obtained a varnish and a resin sheet in the same manner as in Example 1 except that. Moreover, using the resin sheet, it carried out similarly to Example 1, and obtained the resin for evaluation, and the laminated body for evaluation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com