Phenolic hydroxyl group-containing resin, photosensitive composition, resist film, curable composition, and cured product

A technology of phenolic hydroxyl resin and phenolic resin, which is applied in the fields of optics, optomechanical equipment, instruments, etc., and can solve problems that are difficult to balance heat resistance and alkali dissolution speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0255] Hereinafter, the present invention will be specifically described by examples and comparative examples.

[0256] It should be noted that the number average molecular weight (Mn) of the resin prepared in the examples, the weight average molecular weight (MW), and multi-dispersion degrees (MW / Mn) are measured by the following GPC measurement conditions.

[0257] [GPC measurement conditions]

[0258] Measurement device: "HLC-8220GPC" by Dong Cao Co., Ltd.

[0259] Column: Shoex KF802 "(8.0mmф × 300mm) + Shoe Electrical Co., Ltd. (8.0mmф × 300mm) + Shoe Electric Co., Ltd. (8.0mmф ×) (8.0mmф ×) (8.0mmф × 300mm) + Shoe Electronic Co., Ltd. (SHODEX KF802" (8.0mф × 300mm) 300mm) + "Shodex KF804" (8.0mmф × 300mm) made by Showa Electric Co., Ltd.

[0260] Column temperature: 40 ° C

[0261] Detector: ri (differential refractometer)

[0262] Data Processing: "GPC-8020 Model II version 4.30" made by Dong Cao Co., Ltd.

[0263] Expand solvent: tetrahydrofuran

[0264] Flow rate: 1.0ml...

Synthetic example 1

[0283] Synthesis Example 1 Synthesis of phenolic trigonid compound containing carboxylic acid

[0284] To the 2000 ml of the four-mouth flask provided with a cooling tube, 2,5-dimethylphenol was investigated, 4-formylbenzoic acid 150 g (1 mol) was dissolved in 500 ml of acetic acid. After 5 ml of sulfuric acid was added to the ice bath, the heater was heated with a cover heater for 2 hours at 100 ° C, and stirring was carried out. After the reaction, the resulting solution was redditized with water to give a crude product. The crude product was then dissolved in acetone, and then the resulting product was filtered after further use water, and the resulting product was taken as vacuum, and the precursor compound (A-1) 283 g of a pale pink crystal was obtained.

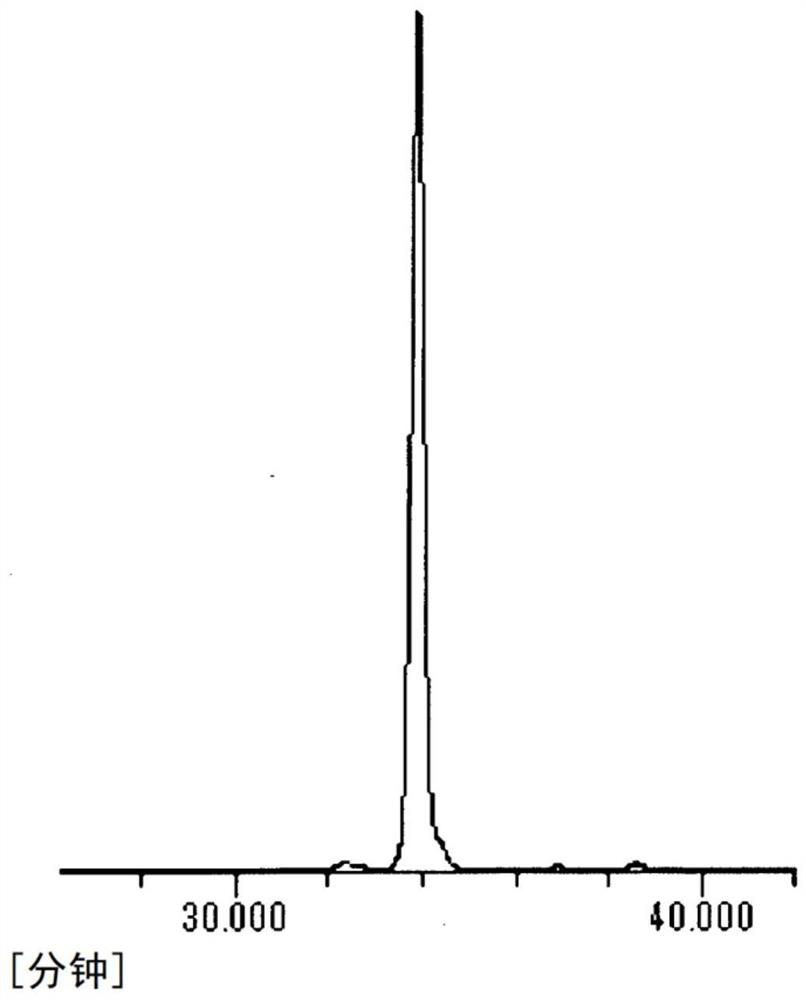

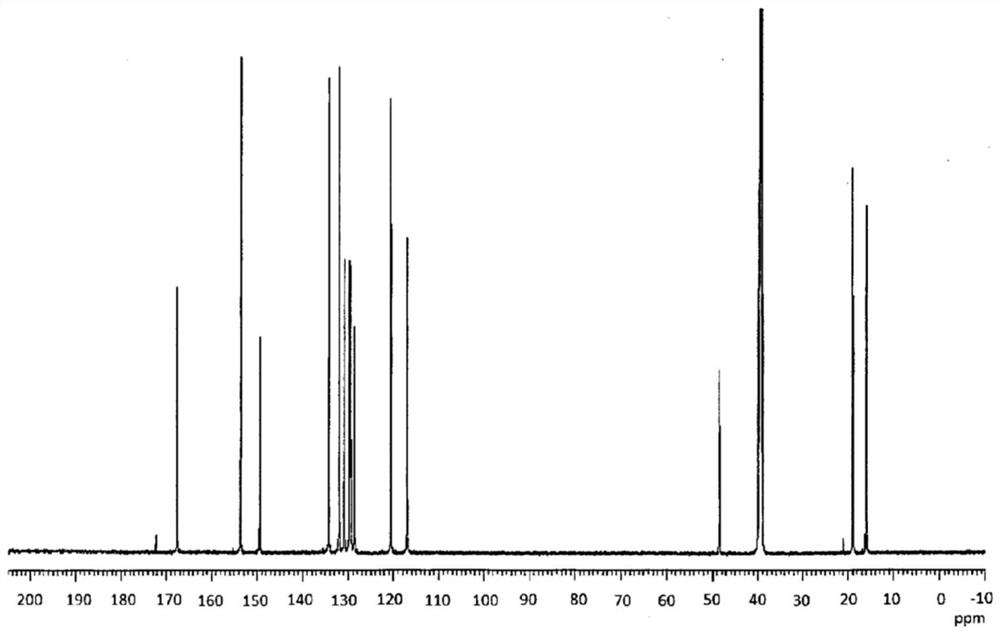

[0285] For the resulting precursor compound (A-1), 13 The C-NMR spectroscopy determines that it is confirmed that it is a compound represented by the following structural formula. In addition, the GPC purity calculated from...

manufacture example 1

[0287] Production Example 1 Synthesis of Phenolic Varcies Phenolic Resins containing carboxylic acids

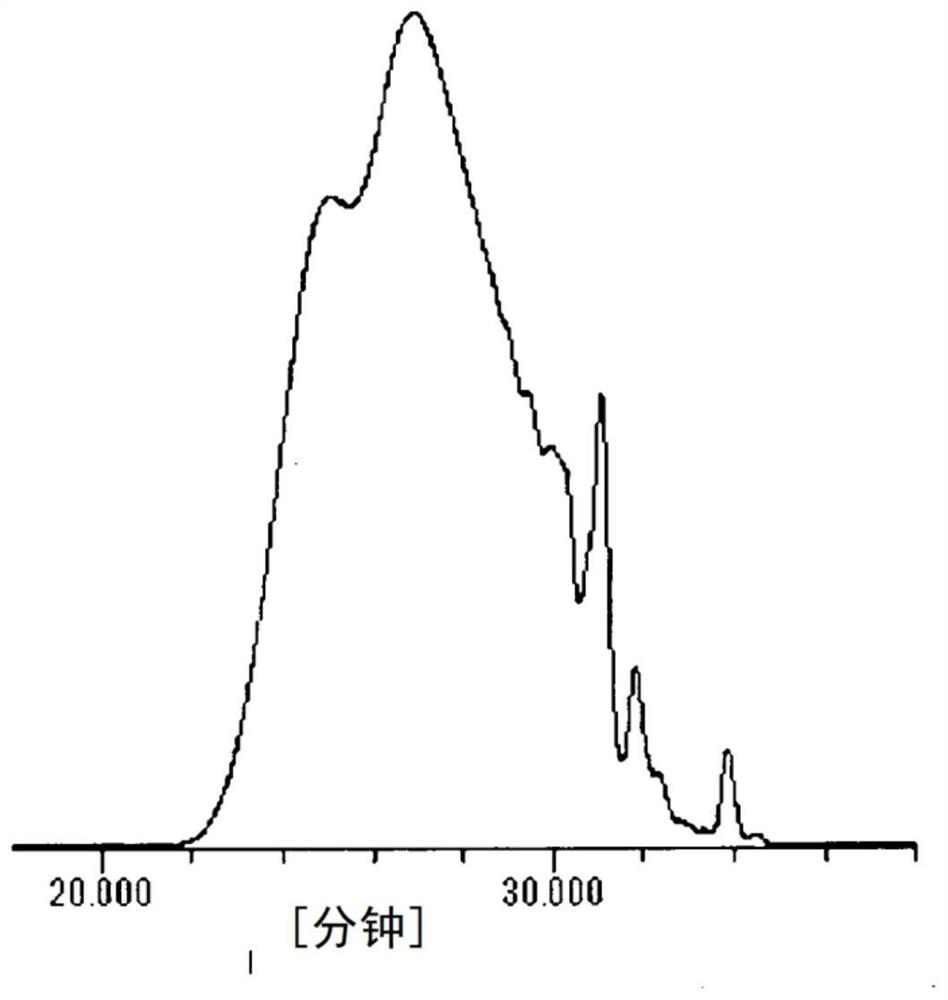

[0288] The precursor compound (A-1) 188 g, 92% polyformaldehyde (B-1) 16 g was introduced into the 1000 ml of the four-mouth flask provided, and was dissolved in 500 ml of acetic acid. After 10 ml of sulfuric acid was added over the ice bath, he was heated to 80 ° C with an oil bath, and the mixture was stirred for 4 hours. After the reaction is completed, water is added to the resulting solution to re-precipitate the crude product. The crude product was then dissolved in acetone, and then the precipitate was filtered, and the phenolic varnoid phenol resin resin (C-1) of the orange powder was filtered.

[0289] The number average molecular weight (Mn) of the obtained phenolic varomidic phenol resin (C-1) was 3946, the weight average molecular weight (MW) was 8504, and the multispice degrees (Mw / Mn) were 2.16.

[0290] GPC spectrum of the obtained phenolic varnish phenol resin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com