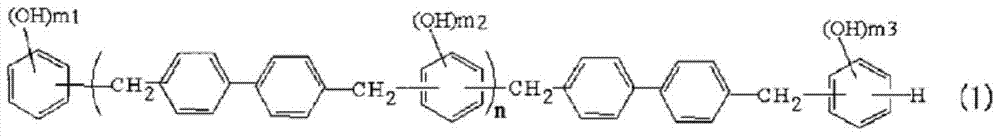

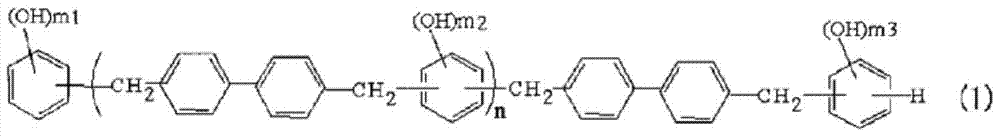

Alkali-developable resin, and photosensitive resin composition using the same

A technology of photosensitive resin and alkali developing type, which is applied in the field of photosensitive resin composition, which can solve the problems that the unexposed part of the coating film cannot be quickly removed, shorten the drying time, etc., and achieve excellent properties and excellent alkali developability , the effect of low-cost productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

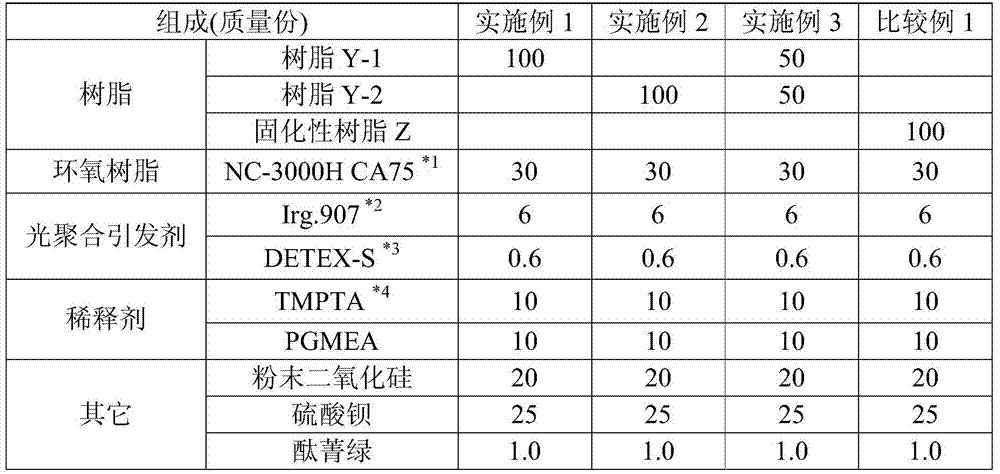

[0132] Hereinafter, the present invention will be described in detail by way of examples and comparative examples, but the present invention is not limited to these examples. In addition, "parts" and "%" in each example represent "parts by weight" and "% by weight", respectively, unless otherwise specified.

Synthetic example 1

[0133] Synthesis Example 1 (Synthesis Example of Resin Y-1)

[0134] 118 parts (1.0 equivalent) of cresol novolac resin [Shonol CRG-951, manufactured by Showa Polymer Co., Ltd., hydroxyl equivalent 118, softening point 96° C., number average molecular weight 750] and propylene glycol monomethyl ether acetate 124.71 parts were charged. , heated to 80°C, and the above mixture was uniformly dissolved. After confirming the dissolution, 37.04 parts (0.5 mol) of glycidol and 0.47 parts of triphenylphosphine were added thereto, heated to 120° C., and reacted for about 8 hours to obtain a reaction product X (resin: intermediate X). As a result of measuring the reaction rate by GPC (gel permeation chromatography), the reaction rate of glycidol was 98%. Next, 32.03 parts (0.17 moles) of trimellitic anhydride were added to the reaction liquid containing the reaction product X, and reacted at 100° C. for about 6 hours to obtain curable resin (Y-1) of the present invention (solid acid val...

Synthetic example 2

[0135] Synthesis Example 2 (Synthesis Example of Resin Y-2)

[0136] Drop into biphenyl aralkyl type phenolic resin [GPH-103, manufactured by Nippon Kayaku Co., Ltd., hydroxyl equivalent 239, softening point 103° C., all phenolic hydroxyl groups are resorcinol hydroxyl groups (resorcinol hydroxyl groups 100%), weight Average molecular weight 3220] 239 parts (1.0 equivalent) and propylene glycol monomethyl ether acetate 222.04 parts, heated to 80 ° C, the above mixture was uniformly dissolved. After confirming the dissolution, 37.04 parts (0.5 mol) of glycidol and 0.83 parts of triphenylphosphine were added thereto, heated to 120° C., and reacted for about 8 hours to obtain a reaction product X (resin: intermediate X). The reaction rate was determined by GPC measurement, and the reaction rate of glycidol was 98%. Next, 57.02 parts (0.3 moles) of trimellitic anhydride were added to the reaction liquid containing the reaction product X, and reacted at 100° C. for about 6 hours t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com