Three-dimensional nano-carbon material for composite strengthening, and preparation method thereof

A nano-carbon material, three-dimensional nano technology, applied in the direction of nanotechnology, can solve the problems of insufficient strength, limited number of functional groups of carbon nanotubes, obstacles, etc., and achieve the effect of increasing lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

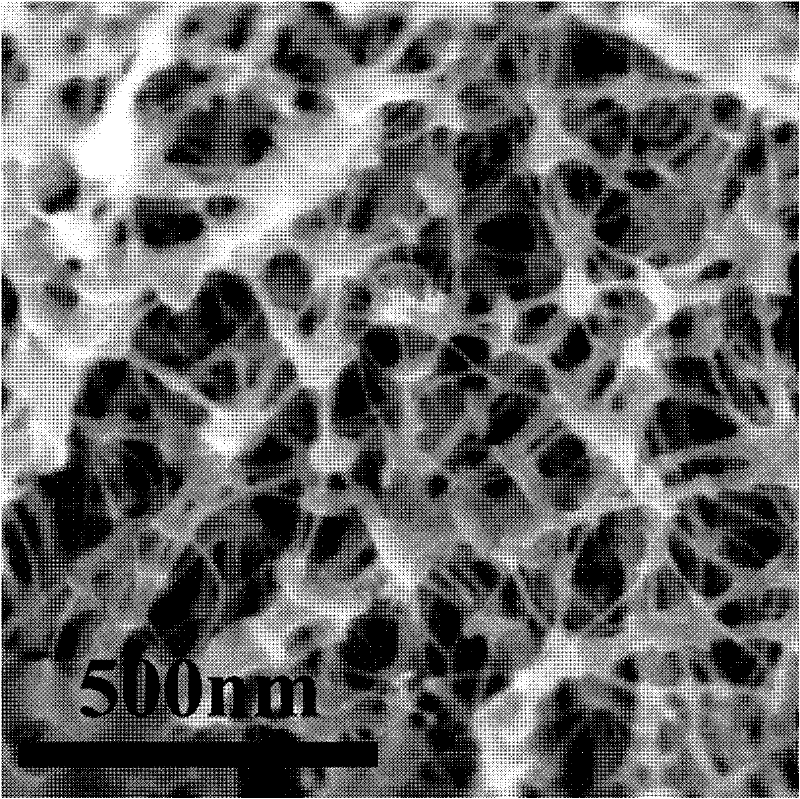

Image

Examples

Embodiment 1

[0025] Dissolve polyethylene in xylene to form a solution with a concentration of 0.001Mol / L; ultrasonically disperse carbon nanotubes with a diameter of 0.8-3nm in xylene to form a solution with a concentration of 0.001Mol / L. The above two solutions were mixed and stirred at 130° C. for 3 hours to gradually precipitate polyethylene crystals on the surface of the carbon nanotubes; stop stirring and let the above solution stand for 3 hours to allow the carbon nanotubes deposited with polyethylene crystals to settle. The settled solid matter was taken out, transferred to ethanol solution at 20°C, and the polymer crystals were further solidified, then taken out, and washed three times with ethanol at 20°C. Then vacuum dry at -25°C for 24 hours.

[0026] The above-mentioned carbon nanotube-polyethylene string crystal structure is treated with 1Mol / L sulfuric acid at 120° C. for 3 hours, neutralized and washed, and then dried to generate a three-dimensional nano-carbon material.

...

Embodiment 2

[0029] Dissolve polyethylene in xylene to form a solution with a concentration of 0.02Mol / L; ultrasonically disperse carbon nanotubes with a diameter of 8-30nm in xylene to form a solution with a concentration of 0.04Mol / L. The above two solutions were mixed and stirred at 130° C. for 5 hours to gradually precipitate polyethylene crystals on the surface of the carbon nanotubes; stop stirring and let the above solution stand for 5 hours to allow the carbon nanotubes deposited with polyethylene crystals to settle. The settled solid matter was taken out, transferred to ethanol solution at 25°C, and further polymer crystals were solidified, then taken out, and washed with ethanol at 25°C for 5 times. Then vacuum dry at -25°C for 5 hours.

[0030] The above-mentioned carbon nanotube-polyethylene string crystal structure was treated with 0.2Mol / L nitric-sulfur mixed acid at 50°C for 15 hours, neutralized and washed, and then dried to generate a three-dimensional nano-carbon material...

Embodiment 3

[0033]Dissolve nylon in glycerin to form a solution with a concentration of 0.05Mol / L; ultrasonically disperse carbon nanotubes with a diameter of 30-100nm in glycerin to form a solution with a concentration of 0.1Mol / L. The above two solutions were mixed and stirred at 172° C. for 5 hours to make the nylon crystallize gradually on the surface of the carbon nanotubes; the stirring was stopped, and the above solution was left to stand for 3 hours to allow the carbon nanotubes deposited with nylon crystals to settle. The settled solid matter was taken out, transferred to ethanol solution at 40°C, and the polymer crystals were further solidified, then taken out, and washed with ethanol at 20°C for 5 times. Then vacuum dry at -25°C for 15 hours.

[0034] The above-mentioned carbon nanotube-nylon string crystal structure was treated with 1Mol / L nitric acid at 80° C. for 10 hours, neutralized and washed, and then dried to generate a three-dimensional nano-carbon material.

[0035] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area | aaaaa | aaaaa |

| Total specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com