Treatment method of wastewater generated during citric acid preparation and preparation method of citric acid

A treatment method and technology of citric acid, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, osmotic/dialysis water/sewage treatment, etc. The effect of reducing grain consumption, reducing environmental protection treatment costs, and reducing environmental protection treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0010] The method for treating the waste water produced by the preparation of citric acid provided by the present invention comprises carrying out membrane filtration of the waste water, the waste water contains citric acid, heteroacids, organic pigments, calcium salts and fermentation residues, wherein the method comprises carrying out the waste water Membrane filtration, the pore size of the membrane is 0.1-0.6 μm.

[0011] According to the present invention, the waste water produced by the preparation of citric acid can be produced by various methods, such as calcium salt method, sulfuric acid acid hydrolysis method, extraction method, electrodialysis method, ion exchange method and chromatography, etc., Considering the components of the wastewater, the method provided by the invention is more suitable for treating the wastewater produced by extracting citric acid through the calcium salt method.

[0012] According to the present invention, the wastewater generated from the...

Embodiment 1

[0051] This embodiment is used to illustrate the treatment method for the wastewater produced by the preparation of citric acid provided by the present invention.

[0052] 50L of the waste water produced by the above-mentioned preparation of citric acid is directly sent into the membrane treatment equipment with a centrifugal pump for membrane filtration, and the flow rate of the waste water is 650 L / h until it is finished. The temperature of the membrane filtration is 63° C., and the pressure is 0.4 MPa. In order to prevent the membrane pores from being blocked by particulate matter, after filtration, the filter membrane is cleaned with compressed air, and the air flow rate is 0.2m 3 / s, the backwash pressure is 0.1MPa, and the backwash time is 25s.

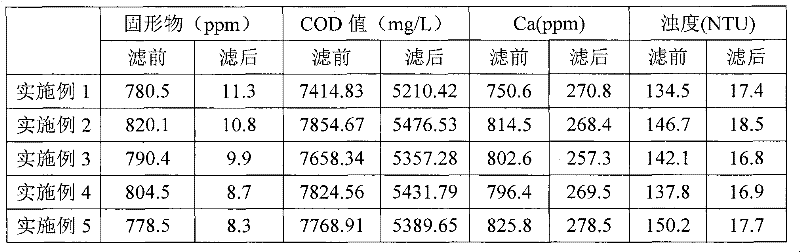

[0053] The indicators of the treated wastewater are shown in Table 1.

Embodiment 2

[0055] This embodiment is used to illustrate the treatment method for the wastewater produced by the preparation of citric acid provided by the present invention.

[0056] 50L of the waste water produced by the above-mentioned preparation of citric acid is directly sent into the membrane treatment equipment with a centrifugal pump for membrane filtration, and the flow rate of the waste water is 680 L / h until it is finished. The temperature of the membrane filtration is 65° C., and the pressure is 0.45 MPa. In order to prevent the membrane pores from being blocked by particulate matter, after filtration, the filter membrane is cleaned with compressed air, and the air flow rate is 0.3m 3 / s, the backwash pressure is 0.1MPa, and the backwash time is 30s.

[0057] The indicators of the treated wastewater are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com