Method for effectively preparing polyimide fiber

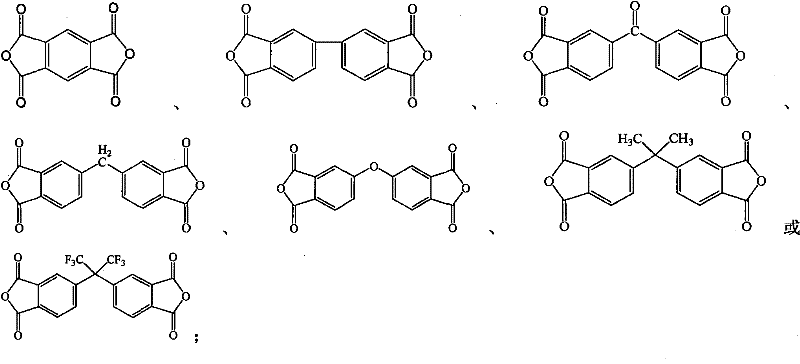

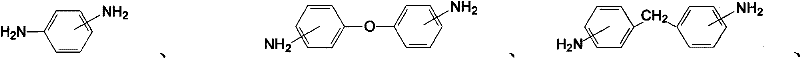

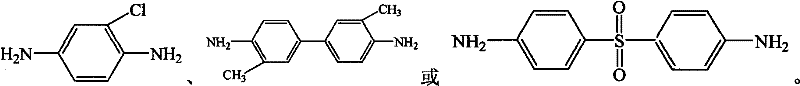

A technology of polyimide fiber and polyamic acid, which is applied in the direction of fiber chemical characteristics, dry spinning method, stretch spinning method, etc., can solve the problems of increased fiber production cost, low production efficiency, long time, etc., and achieve improved production Efficiency, reducing the effect of thermal or chemical cyclization procedures and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Add 0.226kg of 3,4'-diaminodiphenyl ether into 2L of dimethylacetamide and stir until completely dissolved. Afterwards, 0.245 kg of pyromellitic dianhydride was added to the solution in batches, and stirred at room temperature for 6 hours to obtain a pale yellow viscous polyamic acid solution. Add 58g of acetic anhydride and equimolar pyridine into the polyamic acid solution, stir and react for 2-4 hours to obtain the spinning dope.

[0019] The above-prepared spinning stock solution is degassed and then dry-spun on a dry-spinning machine. The length of the tunnel is 10 meters. The temperature of the upper section of the tunnel is 255° C., and the temperature of the lower section is 285° C. Then, it is wound and formed to obtain fibers. The fiber is stretched twice at 430° C. to obtain a high-performance polyimide fiber with a breaking strength of 5.5 cN / dtex and a breaking elongation of 32%.

Embodiment 2

[0021] Add 2.246kg of 4,4'-diaminodiphenylmethane into 20L of dimethylacetamide and stir until completely dissolved. Afterwards, 2.471 kg of pyromellitic dianhydride was added to the solution in batches, and stirred at room temperature for 8 hours to obtain a pale yellow viscous polyamic acid solution. Add 578g of acetic anhydride and equimolar triethylamine into the polyamic acid solution, stir and react for 2-4 hours to obtain the spinning dope.

[0022] The above-prepared spinning stock solution is degassed and then dry-spun on a dry-spinning machine. The length of the tunnel is 12 meters. The temperature of the upper section of the tunnel is 280 ° C, and the temperature of the lower section is 320 ° C. After that, it is wound and formed to obtain fibers. The fiber is stretched 7 times at 500° C. to obtain a high-performance polyimide fiber with a breaking strength of 17 cN / dtex and a breaking elongation of 5%.

Embodiment 3

[0024] Add 0.689kg of phenylenediamine into 10L of N-methylpyrrolidone and stir until completely dissolved. Afterwards, 1.876 kg of biphenyl dianhydride was added to the solution in batches, and stirred at room temperature for 10 hours to obtain a light yellow viscous polyamic acid spinning stock solution.

[0025] The above-prepared spinning stock solution is degassed and then dry-spun on a dry-spinning machine. The length of the tunnel is 9 meters. The temperature of the upper section of the tunnel is 290 ° C, and the temperature of the lower section is 320 ° C. After that, it is wound and formed to obtain fibers. The fiber was stretched 5 times at 510° C. to obtain a high-performance polyimide fiber with a breaking strength of 10.3 cN / dtex and a breaking elongation of 8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com