Multiplayer ceramic chip capacitor (MLCC) based on internal equilibrium electrode paste and ceramic membrane shrinkage rate

A technology for balancing electrodes and ceramic membranes, which is applied in the direction of laminated capacitors, fixed capacitor electrodes, and fixed capacitor dielectrics, etc., which can solve problems such as insulation resistance drop or leakage, dielectric breakdown open circuit, and electrical parameter changes to maintain excellent performance. Effect of reducing failure rate and improving longevity performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

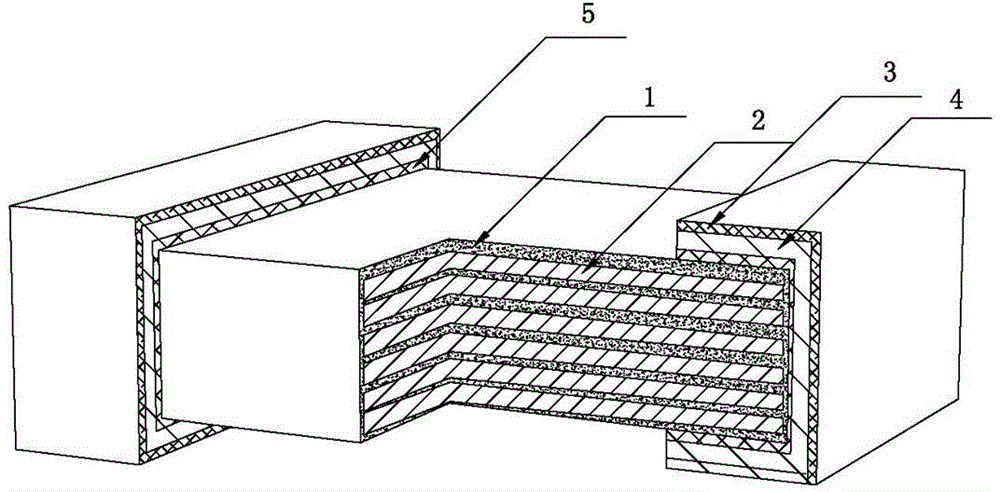

[0021] like figure 1 As shown, the MLCC capacitor based on balancing electrode inner paste and ceramic film shrinkage includes internal electrodes 2, dielectric layers 1 alternately stacked with internal electrodes 2, and coated terminal electrodes. The terminal electrodes include internal electrodes connected to internal electrodes 2. The bottom layer 5 of the terminal electrode, the outermost layer 3 of the terminal electrode connected to the external circuit, and the barrier layer 4 of the terminal electrode between them.

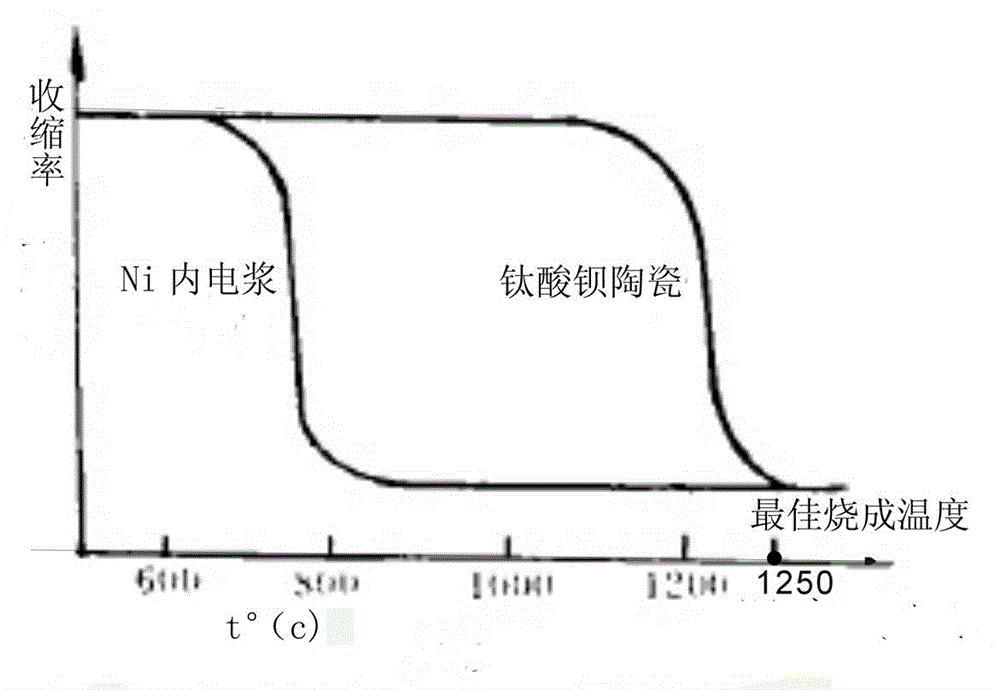

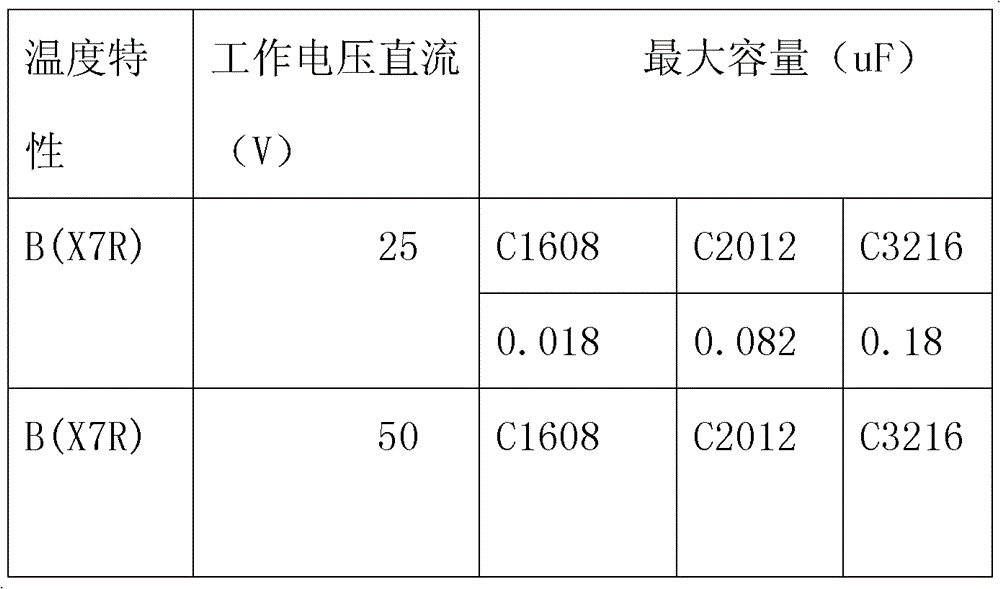

[0022] The internal electrode 2 is made by adding ceramic powder whose main component is barium titanate to the internal electrode slurry which is uniformly mixed with nickel powder with a particle size of 47nm and organic solvent ethyl cellulose, turpentine and acetic acid, and then sintered by silk screen , wherein the mass percent of each component is nickel powder 57%, ethyl cellulose 8%, turpentine 13%, acetic acid 12%, ceramic powder 10%, and the s...

Embodiment 2

[0028] like figure 1 As shown, the MLCC capacitor based on balancing electrode inner paste and ceramic film shrinkage includes internal electrodes 2, dielectric layers 1 alternately stacked with internal electrodes 2, and coated terminal electrodes. The terminal electrodes include internal electrodes connected to internal electrodes 2. The bottom layer 5 of the terminal electrode, the outermost layer 3 of the terminal electrode connected to the external circuit, and the barrier layer 4 of the terminal electrode between them.

[0029] The internal electrode 2 is made by adding ceramic powder whose main component is barium titanate to the internal electrode slurry which is uniformly mixed with nickel powder with a particle size of 47nm and organic solvent ethyl cellulose, turpentine and acetic acid, and then sintered by silk screen , wherein the mass percent of each component is nickel powder 55%, ethyl cellulose 9%, turpentine 11%, acetic acid 10%, ceramic powder 10%, and the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com