Method for preparing titanium dioxide nanocrystalline electrode

A titanium dioxide and nanocrystal technology, applied in capacitor electrodes, photosensitive devices, electrical components, etc., can solve the problems of weak bonding between titanium dioxide particles and substrates, disordered growth, etc., and achieve good conductivity, low cost, and simple methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

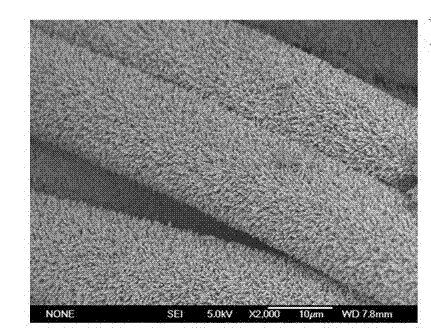

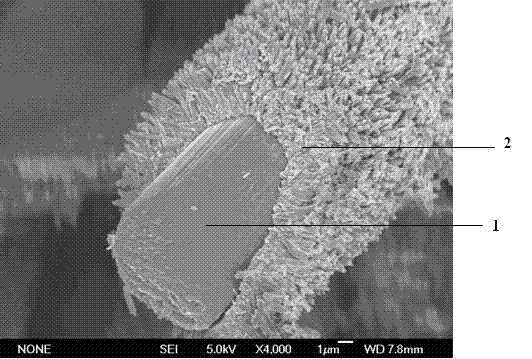

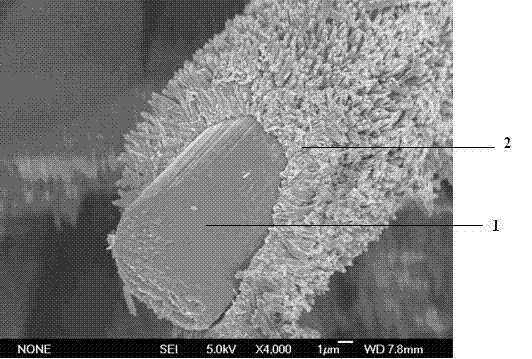

[0019] A mixed solution is directly prepared with butyl titanate, hydrochloric acid and water, wherein the volume percentage of butyl titanate is 4.8%, the volume percentage of hydrochloric acid is 48%, and the rest is water. Put the above mixed solution into a microwave digestion tank, add carbon cloth, put the digestion tank into a microwave chemical workstation, set the temperature at 180°C for microwave heating and reaction for 50 minutes, and obtain a titanium dioxide nanocrystalline electrode. It can be seen that a neat layer of titanium dioxide nanorod arrays is uniformly grown on the surface of carbon fibers, but a small amount of carbon fibers are not completely covered by titanium dioxide nanorods.

Embodiment 2

[0021] The carbon cloth was cleaned, that is, acetone, water, and alcohol were used in sequence, and ultrasonic waves were used for 30 minutes each to obtain a cleaned carbon cloth. Prepare a mixed solution from butyl titanate, hydrochloric acid and water, wherein the volume percentage of butyl titanate is 4.8%, the volume percentage of hydrochloric acid is 48%, and the rest is water. Put the above mixed solution into a microwave digestion tank, and then add Put the processed carbon cloth into the microwave chemical workstation, set the temperature at 180°C for microwave heating for 50 minutes, and obtain a carbon cloth with a layer of titanium dioxide film firmly attached on the surface, that is, a titanium dioxide nanocrystalline electrode.

[0022] The acetone used in the cleaning step of the method is used to clean the organic impurities on the carbon cloth, water is used to wash away the dust, and alcohol is used for the final cleaning process, and can be dried quickly to ...

Embodiment 3

[0025] The carbon cloth was cleaned, that is, acetone, water, and alcohol were used to sonicate for 60 minutes each to obtain a cleaned carbon cloth. Prepare a mixed solution from butyl titanate, hydrochloric acid and water, wherein the volume percentage of butyl titanate is 4.5%, the volume percentage of hydrochloric acid is 41%, and the rest is water. Put the above mixed solution into a microwave digestion tank, and then put Put in the treated carbon cloth, put the digestion tank into the microwave chemical workstation, set the temperature at 170°C for microwave heating for 1 hour, and obtain a layer of titanium dioxide nanorod arrays firmly attached to the surface of the carbon cloth, as can be seen from the scanning electron microscope photos It can be seen that compared with the electrode in Example 2, the titanium dioxide nanorods are slightly thinner and are still arranged vertically on the surface, with no significant difference.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com