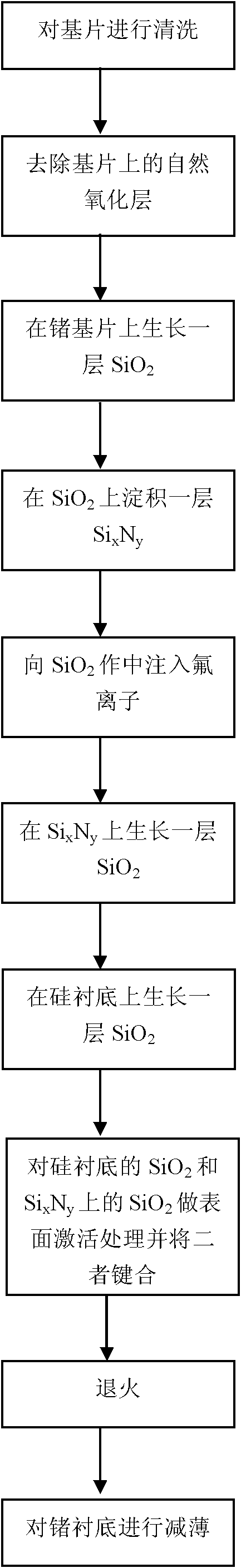

Preparation method of germanium substrate on insulator

A germanium substrate and substrate technology, which is applied in the field of new semiconductor materials and devices, can solve the problems of poor quality of the back interface of GeOI substrate and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] specific implementation plan

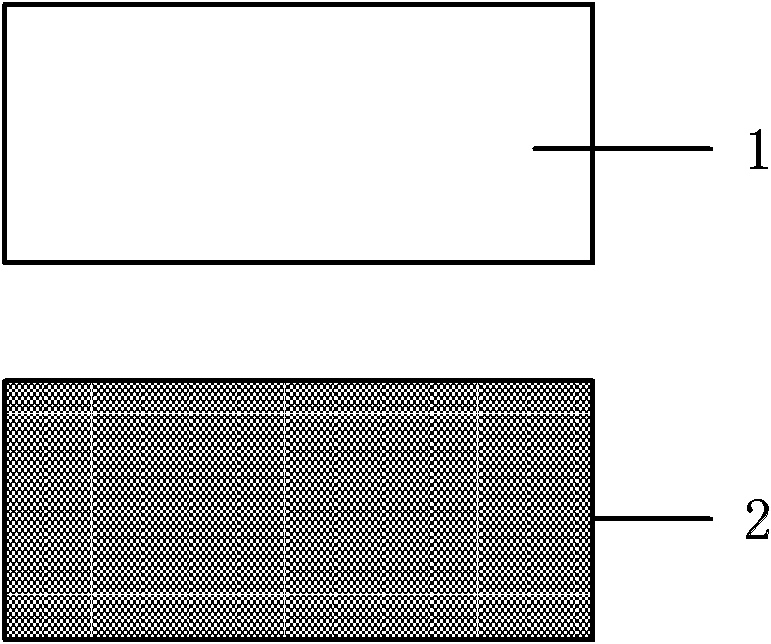

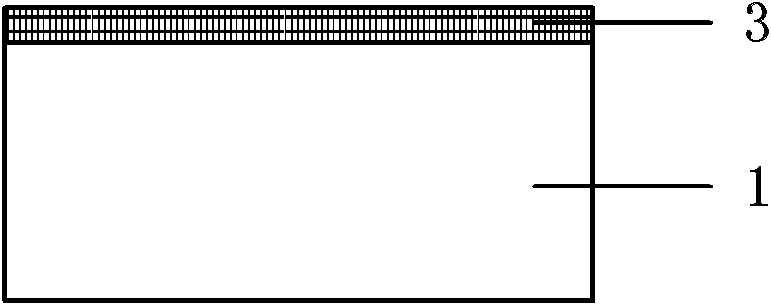

[0032] Step 1. Select a semiconductor germanium substrate and a silicon substrate, as shown in Figure 2(a). Clean the germanium substrate and the silicon substrate respectively. First, the germanium substrate is organically cleaned, soaked and cleaned with acetone and ethanol in turn, and then rinsed with DI water to remove oil and organic pollutants on the germanium substrate. Then wash with hydrochloric acid, heat and boil in dilute hydrochloric acid, and then rinse with DI water to remove inorganic pollutants, metal particles, etc.; first use No. 1 cleaning solution (NH 4 OH:H 2 o 2 :H 2 (0=1:1:5˜1:2:7) to clean the silicon substrate, and then clean it with deionized water to remove particles and organic substances on the substrate. Then use No. 2 cleaning solution (HCl: H 2 o 2 :H 2 O=1:1:6~1:2:8) cleaning, and then cleaning with deionized water to remove metal contamination on the substrate;

[0033] Step 2. Removing the natu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com