Low temperature plasma wastewater treatment device by radial-flow dielectric barrier discharge

A technology of low-temperature plasma and dielectric barrier discharge, which is applied in the direction of light water/sewage treatment, etc., can solve the problem of unsatisfactory wastewater treatment effect, and achieve the effect of prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

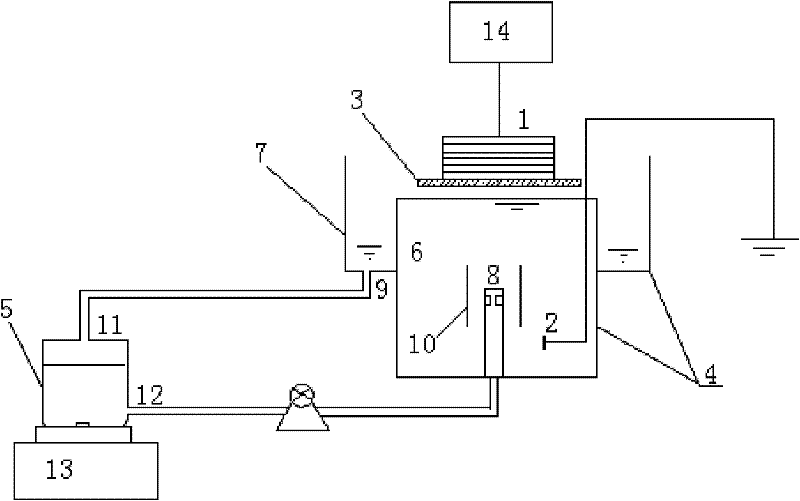

[0031] A radial-flow dielectric barrier discharge low-temperature plasma wastewater treatment device, such as figure 1 As shown, it includes a low-temperature plasma experimental power supply 14, a high-voltage electrode 1 and a ground electrode 2. The lower surface of the high-voltage electrode is provided with a quartz glass layer 3, and the high-voltage electrode 1 is a circular structure with a radius of 50mm; the wastewater treatment device also includes a reactor 4 And waste water tank 5, reactor 4 comprises reaction cylinder 6, overflow reclaimer 7, waste water inlet 8 and waste water outlet 9, and reaction cylinder 6 is the hollow cylindrical structure that one end is open and the other end is closed, and the height of this cylindrical structure is 100mm, the radius is 50mm, the vertical distance between the opening edge of the reaction cylinder 6 and the lower surface of the quartz glass layer 3 is 8mm; Directly above the open end of 6, the ground electrode 2 is set i...

Embodiment 2

[0036] Radial flow dielectric barrier discharge low-temperature plasma wastewater treatment device as described in Example 1, the difference is that the high-voltage pole 1 is a circular structure with a radius of 40mm, the height of the reaction cylinder 6 is 120mm, and the radius is 40mm. The vertical distance between the edge of the opening of 6 and the lower surface of the quartz glass layer 3 is 10mm.

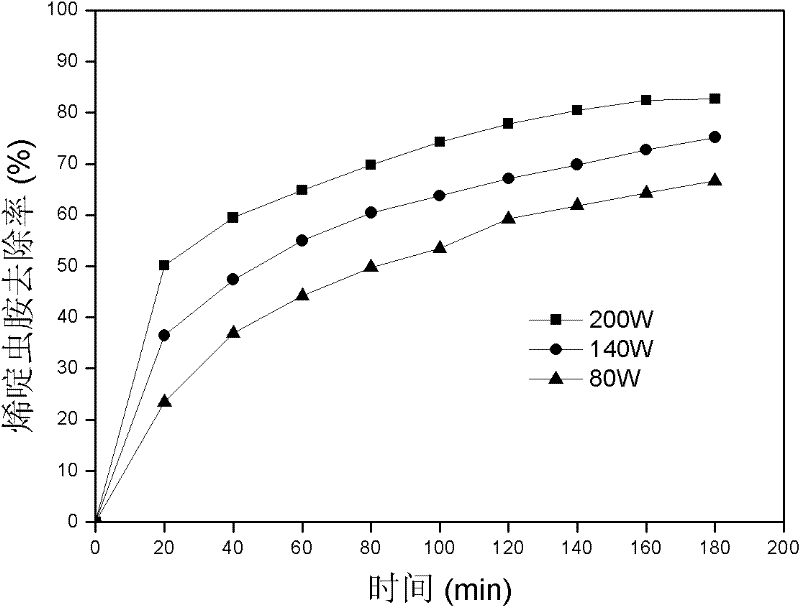

[0037]Dielectric barrier discharge low-temperature plasma was used to degrade methylene blue dye wastewater with an initial concentration of 200mg / L. The concentration of dye wastewater in the degradation process was measured at the maximum absorption wavelength of 662nm with an ultraviolet spectrophotometer. The degradation effect of the body on methylene blue is as follows Figure 4 As shown, when the discharge power is 200W, after 180min of degradation, the removal rate of methylene blue reaches more than 84%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com