Manufacturing method of proPiconazole

A production method and technology for propiconazole, applied in the field of pesticides, can solve problems such as difficult dehydration, influence on refining yield, stickiness of materials, etc., and achieve the effects of reducing waste water discharge, reducing environmental pollution and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

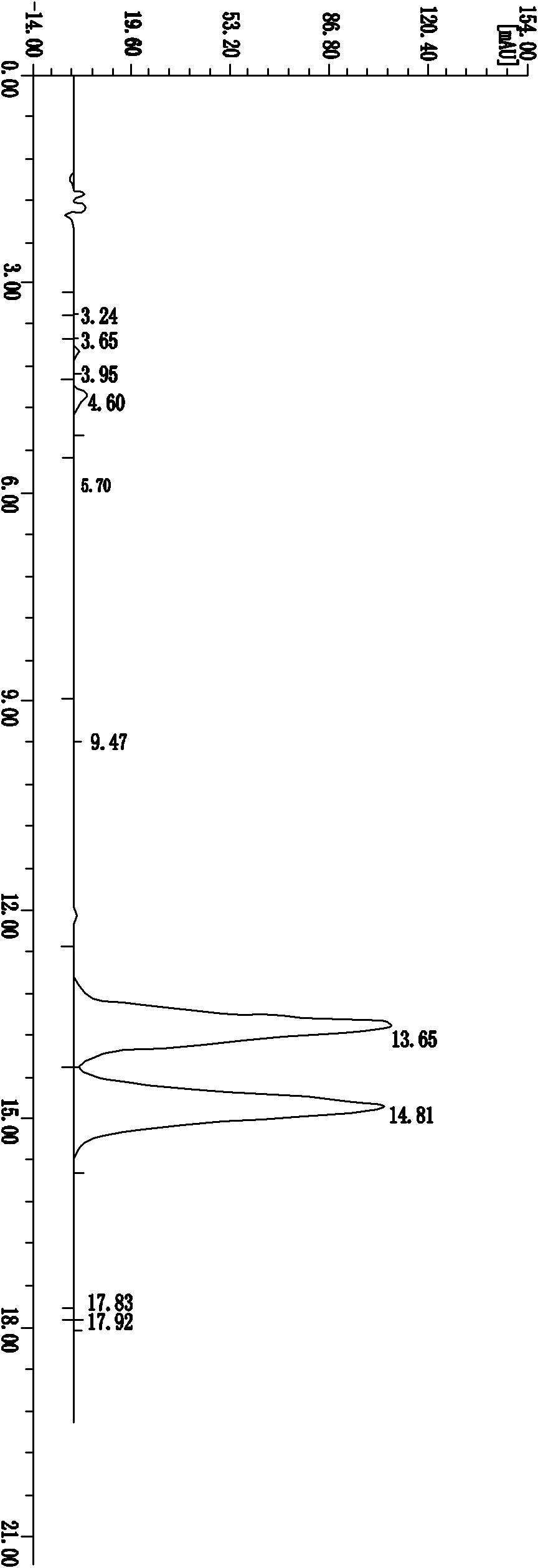

Image

Examples

Embodiment 1

[0053] According to the ratio of substance amount 2,4-dichloroacetophenone: 1,2-pentanediol: the ratio of catalyst phosphomolybdic acid is 1:1.07:0.02, 2,4-dichloroacetophenone and 1, 2-Pentanediol was refluxed under the action of catalyst phosphomolybdic acid to carry out cyclization reaction. At this time, the temperature was 86° C., and the reaction time was 8 hours. After the cyclization reaction was finished, the bromination reaction was carried out after the catalyst phosphomolybdic acid was recovered by filtration. Said bromination reaction temperature is 35 ℃, and bromine drip rate is 18Kg / h, after bromination reaction finishes, keep 0.3Mpa and stir 1h, reclaim hydrogen bromide gas, desolventize obtains 2-bromomethyl-(2, 4-dichlorophenyl)-4-propyl group-1,3-dioxolane, in the present invention, first reclaims and removes catalyst phosphomolybdic acid to the synthesized cyclized product, then carries out bromination reaction, and bromide collects The rate can reach more ...

Embodiment 2

[0056] According to the ratio of substance amount 2,4-dichloroacetophenone: 1,2-pentanediol: the ratio of catalyst phosphomolybdic acid is 1:1.13:0.06, 2,4-dichloroacetophenone and 1, 2-Pentanediol is refluxed under the action of catalyst phosphomolybdic acid to carry out cyclization reaction. At this time, the temperature is 83-88°C and the reaction time is 8 hours. After the cyclization reaction is completed, the catalyst phosphomolybdic acid is recovered by filtration and bromination reaction is carried out , the bromination reaction temperature is 36°C, and the bromine drop rate is 19Kg / h. After the bromination reaction is completed, keep stirring at 0.4Mpa for 1.5h, recover hydrogen bromide gas, and remove the solvent to obtain 2-bromomethyl- (2,4-dichlorophenyl)-4-propyl group-1,3-dioxolane, in the present invention, first recover and remove catalyst phosphomolybdic acid to the synthesized cyclized product, then carry out bromination reaction, The yield of bromide can re...

Embodiment 3

[0059] According to the ratio of substance amount 2,4-dichloroacetophenone: 1,2-pentanediol: the ratio of catalyst phosphotungstic acid is 1:1.20:0.1, 2,4-dichloroacetophenone and 1, 2-Pentanediol is refluxed under the action of catalyst phosphotungstic acid for cyclization reaction. At this time, the temperature is 85-89°C and the reaction time is 4-8 hours. bromination reaction, the bromination reaction temperature is 37 ° C, and the bromine drop rate is 20Kg / h, after the bromination reaction is completed, keep stirring at 0.5Mpa for 2h, recover hydrogen bromide gas, and remove the solvent to obtain 2-bromomethyl -(2,4-dichlorophenyl)-4-propyl-1,3-dioxolane, in the present invention, first recover and remove catalyst phosphomolybdic acid to the synthesized cyclized product, then carry out bromination reaction , the yield of bromide can reach more than 98%wt, and the mass content of bromide is more than 98%, reducing the monobromide and dibromide of ketone due to the re-decom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com