Water-soluble nano bright grease

A water-soluble, nano-technology, applied in polishing compositions, chemical instruments and methods, etc., can solve problems such as environmental pollution, lack of raw material sources, etc., and achieve the effects of good moisture resistance, maintaining the vividness of the paint film, and a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] Embodiment (taking 100kg raw material as example):

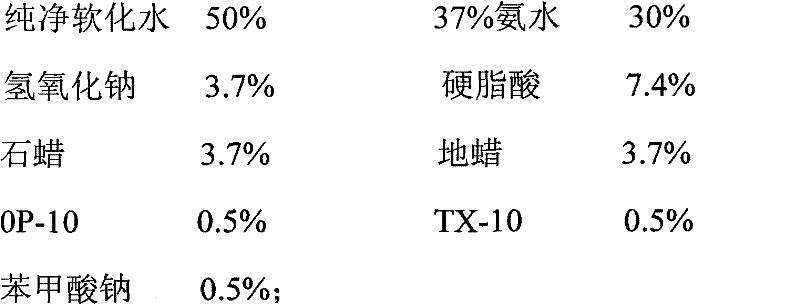

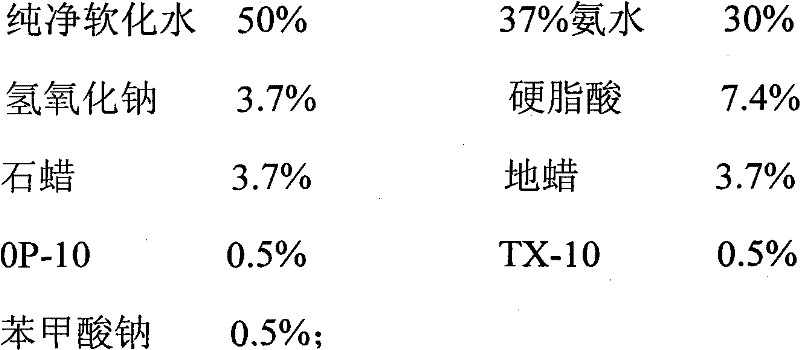

[0020] The raw materials are taken by weighing the weight percentages of the above-mentioned raw materials as follows:

[0021] Pure demineralized water 50kg; ammonia water 30kg; sodium hydroxide 3.7kg; stearic acid 7.4kg; paraffin wax 3.7kg; ozokerite 3.7kg; OP-10 0.5kg TX-10 0.5kg;

[0022] Prepare water-soluble nano bright cream according to the following preparation method:

[0023] First, pack 50kg of pure softened water in the above raw materials into one portion of 16.7kg and six portions of 5.55kg; 30kg of ammonia water into seven portions of 4.285kg; 3.7kg of sodium hydroxide into seven portions of 0.528kg The number of parts; the reaction time of the whole preparation process needs 168 hours to complete, and the raw materials are added in different periods.

[0024] After the raw material packaging is completed, 3.7kg of paraffin and 3.7kg of ozokerite are added to the reactor. The reactor is a reactor wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com