Breakdown fluid and preparation method thereof

A technology of fracturing fluid and lye, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as shrinkage, lower fracturing fluid viscosity, and poor technical and economic effects, so as to improve adaptability and durability thermal performance, reducing hydraulic fracturing power demand, and inhibiting the effect of coagulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] a. First prepare the thickener, the steps are as follows:

[0055] 1. Pretreat the melon collagen powder under high temperature steam;

[0056]2. Pump 50 liters of mixed solvent of ethanol and water (volume ratio 4:1) into the reaction kettle, start the mixer, slowly add 15kg of melon collagen powder (flaky); then add 0.1kg of cetyl trimethyl Ammonium chloride as a phase transfer catalyst;

[0057] 3. Stir and heat up to 30°C-40°C at a heating rate of 1°C-3°C / min;

[0058] 4. Pump 0.9kg NaOH and 2.5 liters of H 2 O, alkalized for 30 minutes;

[0059] 5. After the alkalization finishes, add dropwise the propylene oxide (mol ratio 1: 1), pump 0.9kg NaOH and 2.5 liters of H 2 O;

[0060] 6. Rise to 50-70°C at a heating rate of 1°C-3°C / min, and react for 4-6 hours;

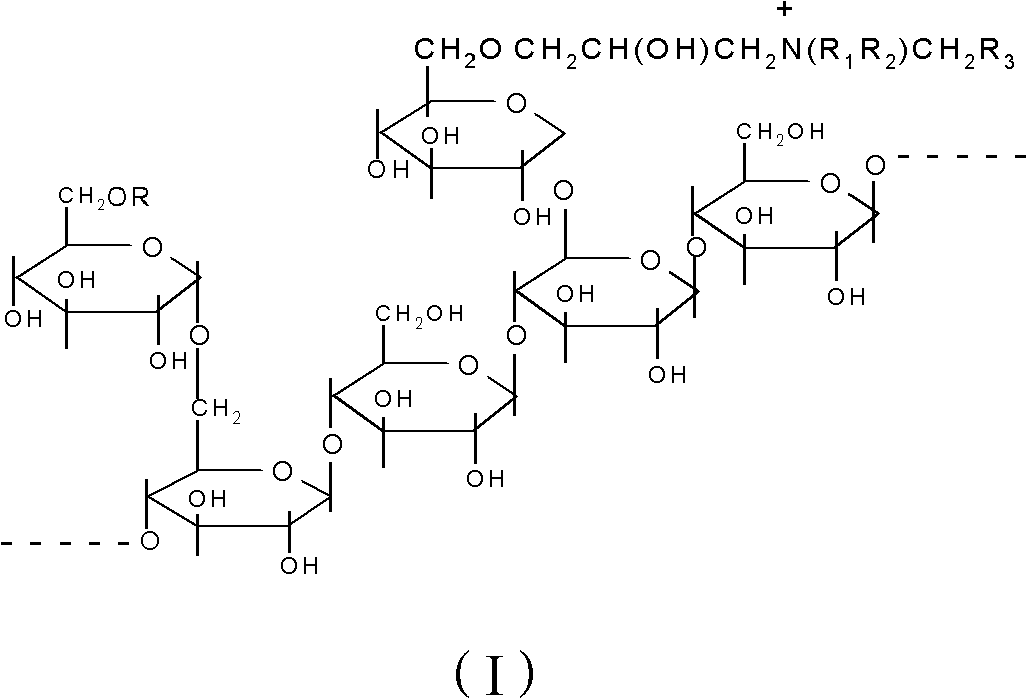

[0061] 7. After the reaction, wash with glacial acetic acid and ethanol, then dry and pulverize to obtain the thickener of the following formula:

[0062]

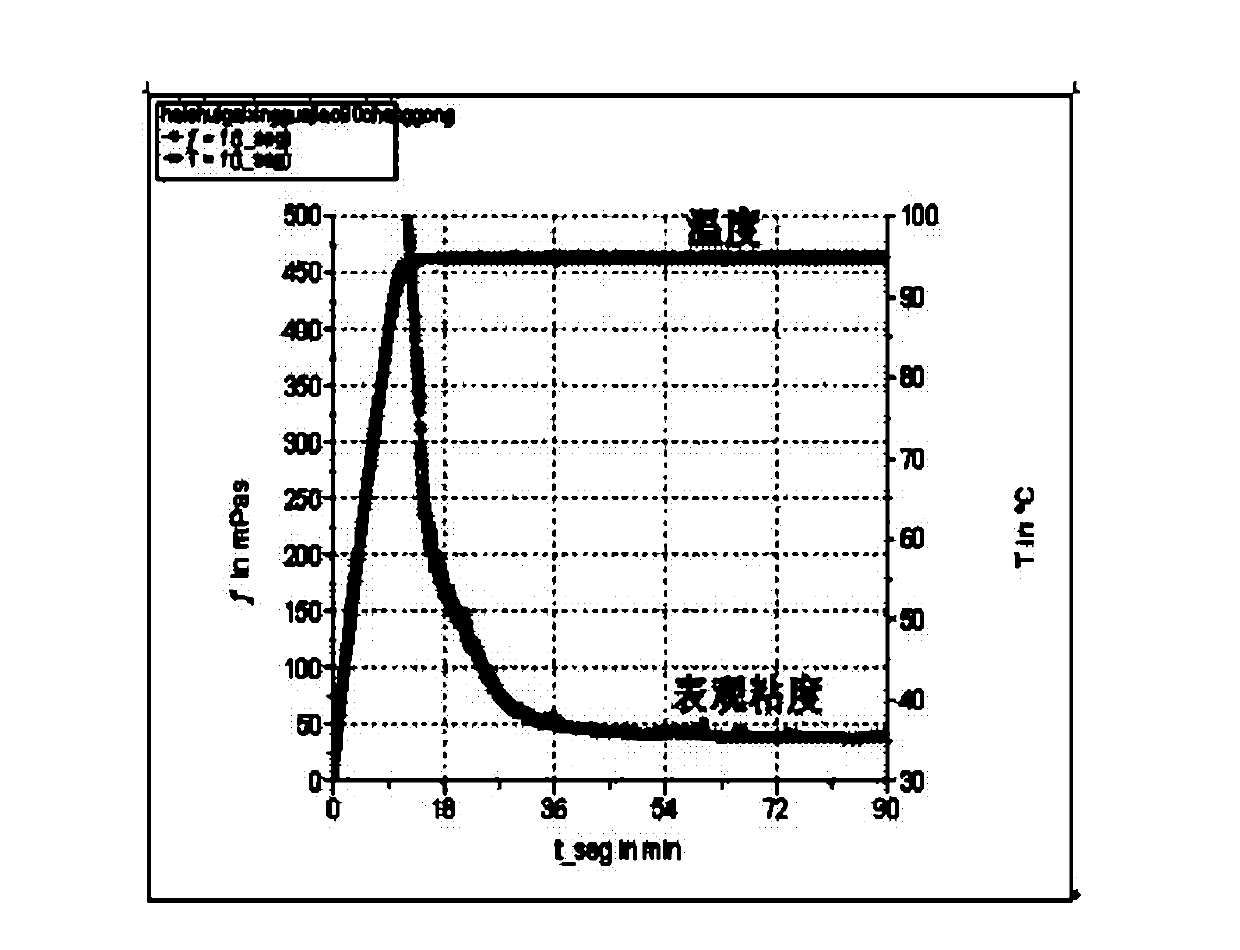

[0063] b. Use a graduated cylinder to meas...

Embodiment 2

[0065] a. First prepare the thickener, the steps are as follows:

[0066] 1. Pretreat the melon collagen powder under high temperature steam;

[0067] 2. Pump the mixed solvent (volume ratio 4:1) of 50 liters of ethanol and water into the reaction kettle, start the stirrer, and slowly add 15Kg melon collagen powder (flaky). Add 0.1kg cetyltrimethylammonium chloride as phase transfer catalyst;

[0068] 3. Stir and heat up to 30°C to 40°C at a heating rate of 1°C to 3°C / min;

[0069] 4. Pump 0.9kg NaOH and 2.5 liters of H 2 O, and alkalized for 30 minutes;

[0070] 5. After alkalization finishes, add dropwise the ion pair monomer 3-chloro-2-hydroxypropyl-N of 9.75kg, N-dimethyl-carboxybetaine and 4.0kg chloroethanol (molar ratio 1: 1), Pump in 0.9 kg NaOH and 2.5 liters of H 2 O;

[0071] 6. Rise to 50-70°C at a heating rate of 1°C-3°C / min, and react for 4-6 hours;

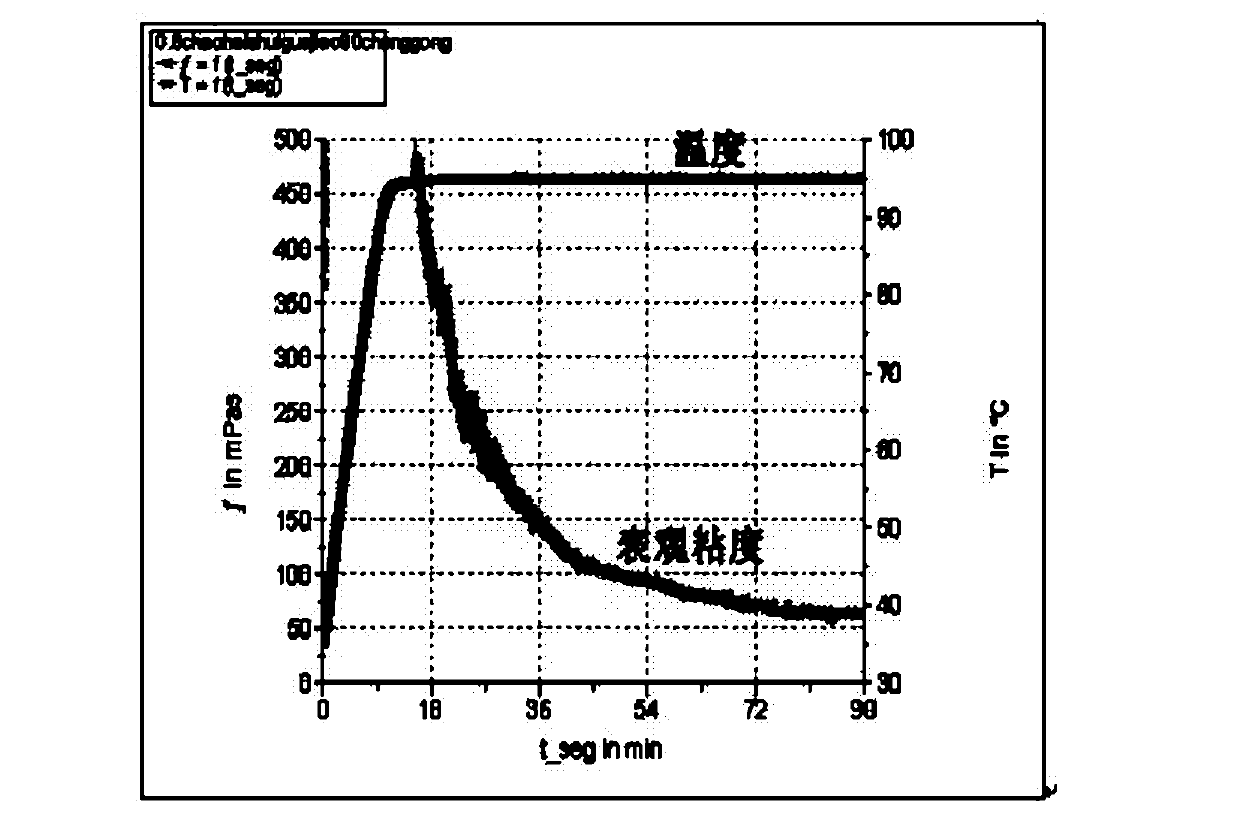

[0072] 7. After the reaction, wash with glacial acetic acid and ethanol, then dry and pulverize to obtain ...

Embodiment 3

[0076] a. First prepare the thickener, the steps are as follows:

[0077] 1. Pretreat the melon collagen powder under high temperature steam;

[0078] 2. Pump 50 liters of mixed solvent of ethanol and water (volume ratio 4:1) into the reaction kettle, start the mixer, slowly add 15Kg of melon collagen powder (flaky); add 0.1kg of cetyl trimethyl chloride Ammonium chloride is used as a phase transfer catalyst;

[0079] 3. Stir and heat up to 30°C to 40°C at a heating rate of 1°C to 3°C / min;

[0080] 4. Pump 0.9kg NaOH and 2.5 liters of H 2 O, and alkalized for 30 minutes;

[0081] 5. After alkalization finishes, add dropwise the ion pair monomer 2 of 9.42kg, 3-epoxypropyl-N, the sodium chloroacetate aqueous solution of N-dimethyl-sulfobetaine and 4.7kg (molar ratio 1: 1), pump 0.9kg NaOH and 2.5 liters of H 2 O.

[0082] 6. Rise to 50-70°C at a heating rate of 1°C-3°C / min, and react for 3-5 hours;

[0083] 7. After the reaction, wash with glacial acetic acid and ethanol,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com