Magnesium-containing superlattice hydrogen storage alloy and preparation method thereof

A technology of hydrogen storage alloy and superlattice, which is applied in the field of magnesium-containing superlattice hydrogen storage alloy and its preparation, can solve the problems of poor high-current discharge capability, hindering application, and poor battery self-discharge performance, and achieve high-current discharge Strong ability, improved market competitiveness, and low self-discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

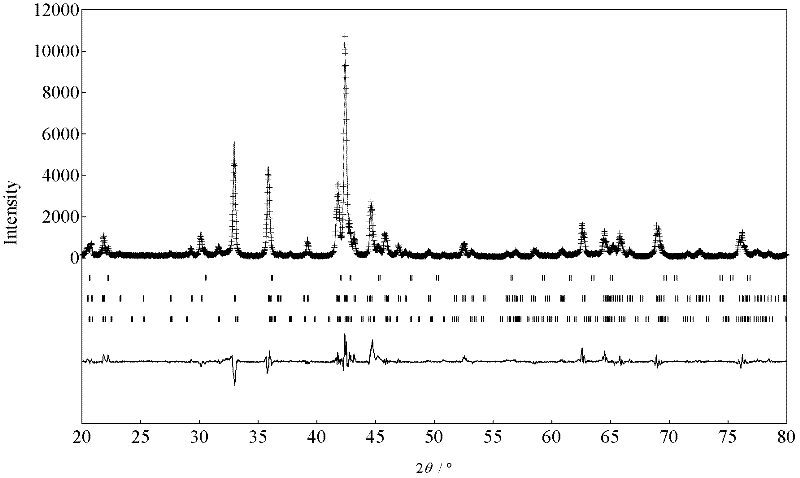

Image

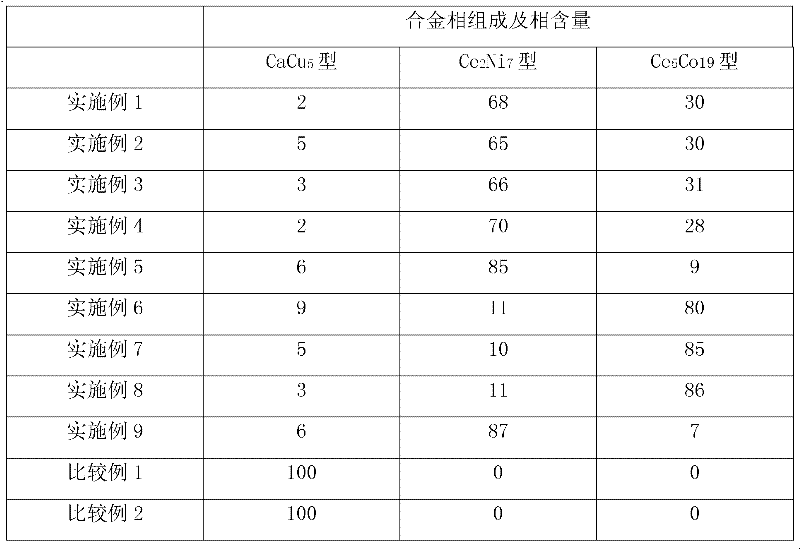

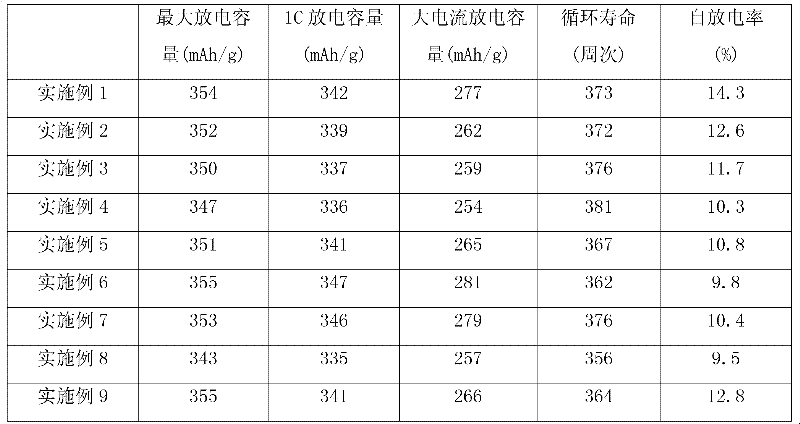

Examples

Embodiment 1

[0021] According to the chemical formula Mm 0.66 La 0.2 Mg 0.13 Zr 0.01 (Ni 0.94 Al 0.06 ) 3.5 For batching, the subscript values of each component represent the molar ratio, and the active ingredient content (mass percentage) in each component is: La≥99.5%, Mm total amount of rare earth≥99.5%, Mg≥99.9%, Zr≥99.5%, Ni≥99.95%, Al≥99.5%, the raw materials are made into hydrogen storage alloy powder after vacuum induction melting, vacuum heat treatment and low-temperature impact mill crushing.

Embodiment 2

[0023] According to the chemical formula Mm 0.71 La 0.15 Mg 0.13 Zr 0.01 (Ni 0.94 Al 0.06 ) 3.5 For batching, the subscript values of each component represent the molar ratio, and the active ingredient content (mass percentage) in each component is: La≥99.5%, Mm total amount of rare earth≥99.5%, Mg≥99.9%, Zr≥99.5%, Ni≥99.95%, Al≥99.5%, the raw materials are made into hydrogen storage alloy powder after vacuum induction melting, vacuum heat treatment and low-temperature impact mill crushing.

Embodiment 3

[0025] According to the chemical formula Mm 0.78 La 0.08 Mg 0.13 Ti 0.01 (Ni 0.94 Al 0.06 ) 3.5 For batching, the subscript values of each component represent the molar ratio, and the active ingredient content (mass percentage) in each component is: La≥99.5%, Mm total amount of rare earth≥99.5%, Mg≥99.9%, Ti≥99.5%, Ni≥99.95%, Al≥99.5%, the raw materials are made into hydrogen storage alloy powder after vacuum induction melting, vacuum heat treatment and low-temperature impact mill crushing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com