Environmentally-friendly digital inkjet textile printing ink with reactive dye and preparation method thereof

A reactive dye, digital inkjet technology, applied in the field of environmentally friendly digital inkjet textile printing ink and its preparation, can solve the problems of easy hydrolysis and low dye uptake, achieve soft hand feel, improve stability, and be beneficial to the environment protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

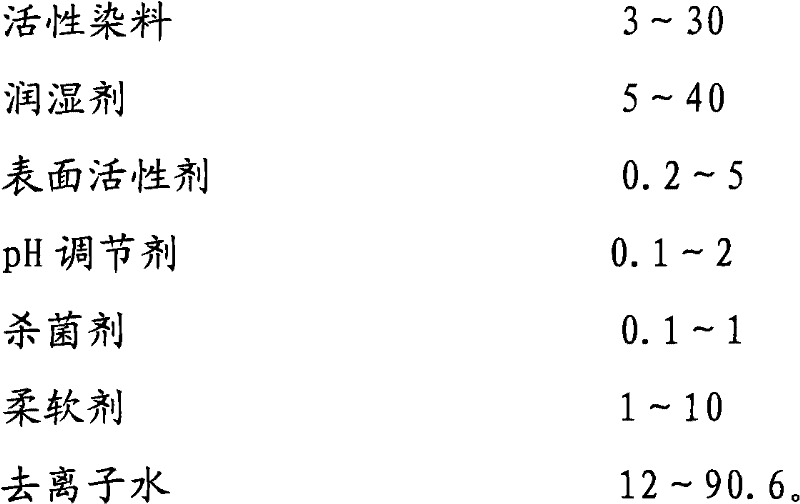

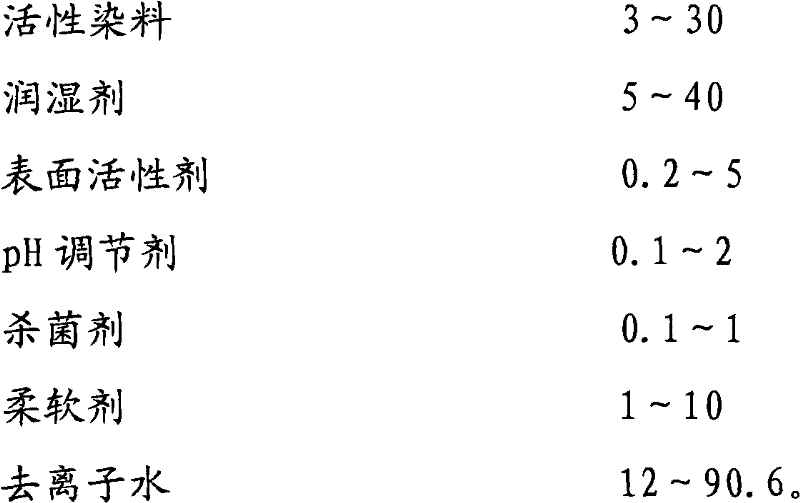

Method used

Image

Examples

example 1

[0027] 1. The environmentally friendly digital inkjet textile printing ink with reactive dyes is prepared according to the following ratio, see Table 1.

[0028] Table 1

[0029] components

Content (weight%)

Deionized water

72.7

glycerin

5

10

0.5

2.5

1

0.3

Environmentally friendly reactive dye black 8

8

total

100

[0030] 2. Preparation method:

[0031] Put the above components into the mixing container in sequence, stir at 500-3000rpm for 30-120 minutes, and then use filter membranes with a pore size of 1um, 0.5um, and 0.22um to filter step by step to obtain an environmentally friendly black reactive dye. Finished digital inkjet textile printing ink.

example 2

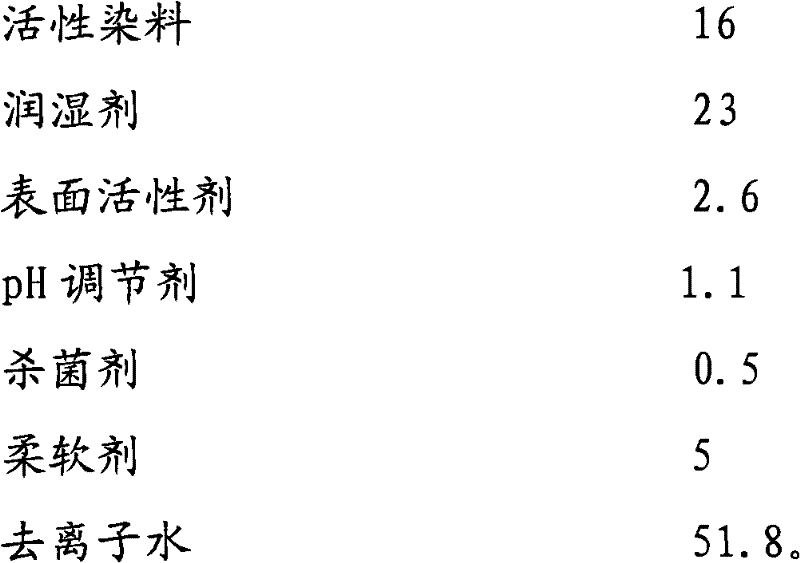

[0033] 1. The environmentally friendly digital inkjet textile printing ink with reactive dyes is prepared according to the following ratio, see Table 2.

[0034] Table 2

[0035] components

Content (weight%)

Deionized water

35.5

16

15

0.2

1.8

3

0.5

Environmentally friendly reactive dye black 8

28

total

100

[0036] 2. Preparation method:

[0037] Put the above components into the mixing container in sequence, stir at 500-3000rpm for 30-120 minutes, and then use filter membranes with a pore size of 1um, 0.5um, and 0.22um to filter step by step to obtain an environmentally friendly black reactive dye. Finished digital inkjet textile printing ink.

example 3

[0039] 1. The environmentally friendly digital inkjet textile printing ink with reactive dyes is prepared according to the following ratio, see Table 3.

[0040] table 3

[0041] components

Content (weight%)

Deionized water

60.7

glycerin

10

10

0.1

1

3

[0042] Isothiazolinone

0.2

Environmentally friendly reactive dye black 8

15

total

100

[0043] 2. Preparation method:

[0044] Put the above components into the mixing container in sequence, stir at 500-3000rpm for 30-120 minutes, and then use filter membranes with a pore size of 1um, 0.5um, and 0.22um to filter step by step to obtain an environmentally friendly black reactive dye. Finished digital inkjet textile printing ink.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com