Method for producing grape seed extract

A technology of grape seed and extract, which is applied in the field of food processing, can solve the problems of increasing monomer content, reducing monomer polyphenol content, and long time consumption, and achieves the effect of low monomer content and high polyphenol content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1 Production of grape seed extract

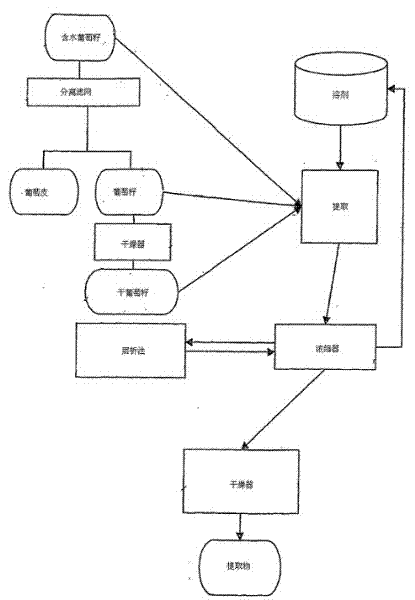

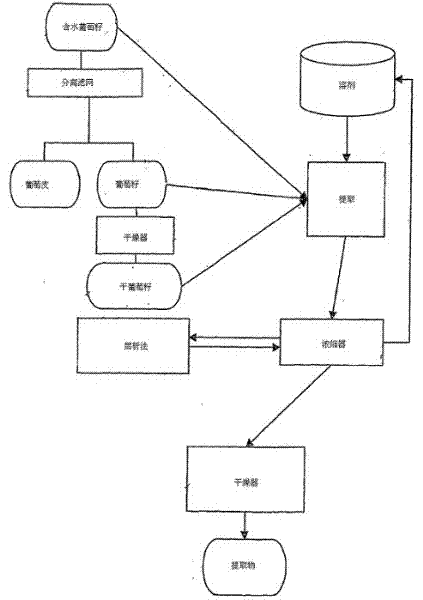

[0037] The method for producing grape seed extract of the present embodiment, comprises the following steps:

[0038] 1) Using a double-sided separator to separate the grape marc obtained from the filter press for the production of biological red grape juice for 72 hours;

[0039] 2) Dry the obtained grape seeds with a hot air dryer for about 4 hours at a temperature not higher than 60°C until the humidity of the grape seeds reaches 7%;

[0040] 3) Treat the obtained grape seeds with a mixture of alcohol and water (70:30) at 40-50°C, divide into four cycles, each cycle is 1 hour, and the ratio of drug to solvent is 1:3. The residual grape seeds are recovered by the net, and the liquid phase is concentrated to remove alcohol; the recovered alcohol can be used again for other extraction processes;

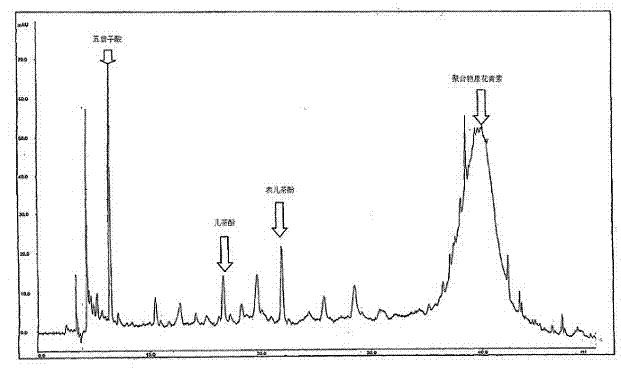

[0041] 4) Put the aqueous phase containing the main extract in a spray dryer to obtain the main product with a total polyphenol ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com