Argon arc welding method suitable for TiAl-based alloy material and titanium alloy

A titanium alloy and base alloy technology, applied in arc welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of easy cracks in TiAl, limited joint forms, and inapplicability, so as to avoid welding cracks and joint crack sensitivity Reduced, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

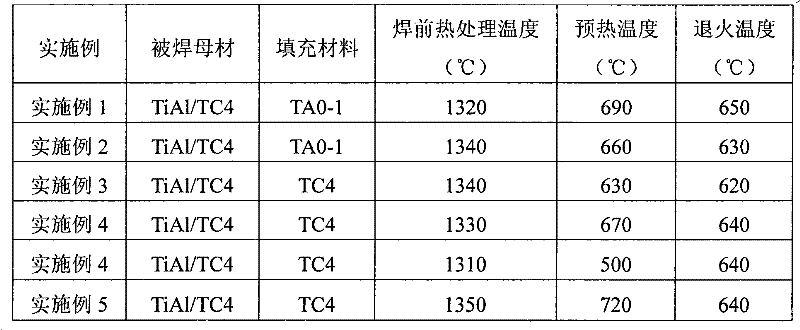

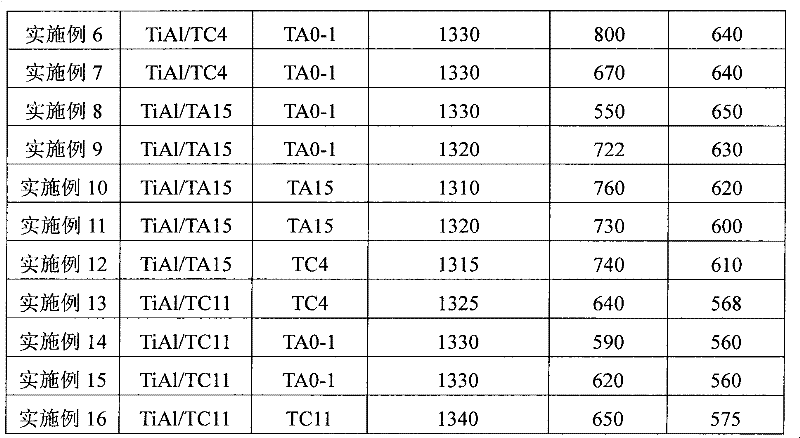

[0024] The filling material that each embodiment of table 1 uses

[0025]

[0026]

[0027] The welding of TiAl base alloy and titanium alloy, the steps of this method are:

[0028] (1) base material to be welded and filler material in the embodiment are listed in table 1 respectively, and welding wire is prepared, and clean welding wire surface;

[0029] (2) The size of the TiAl and titanium alloy welding test plate is 90×50×2.5 mm, and the TiAl-based material is subjected to pre-weld heat treatment, and the heat treatment system is shown in Table 1;

[0030](3) Process the welding groove, blunt edge 0.5mm, unilateral angle 35°, remove the oxide film within 10mm on both sides of the groove to make it bright, and scrub with acetone before welding;

[0031] (4) The welding between the TiAl-based alloy and the titanium alloy adopts the argon tungsten arc welding method, and the welding wire described in Table 1 is used for the welding between the TiAl-based alloy and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com