Barium strontium titanate multilayered film, and preparation method thereof

A multi-layer thin film, barium strontium titanate technology, applied in the direction of chemical instruments and methods, titanium compounds, layered products, etc., can solve the problems of high tuning rate, low dielectric loss, and application requirements, and achieve superior performance , low production cost, high dielectric constant and high tuning rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

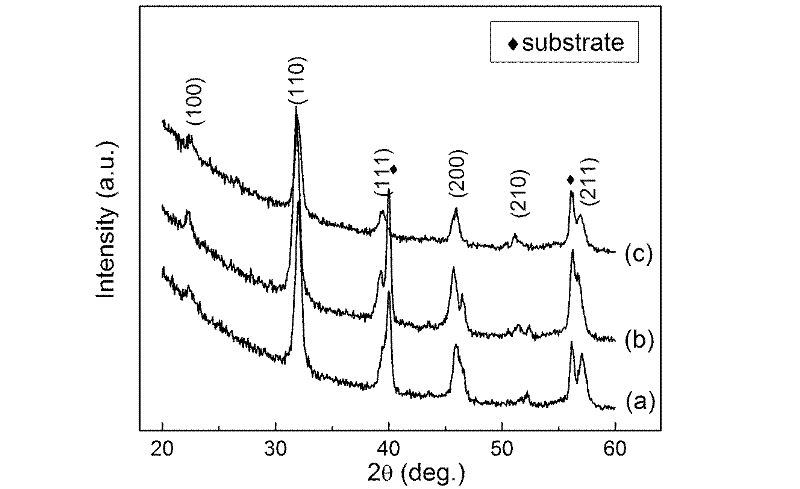

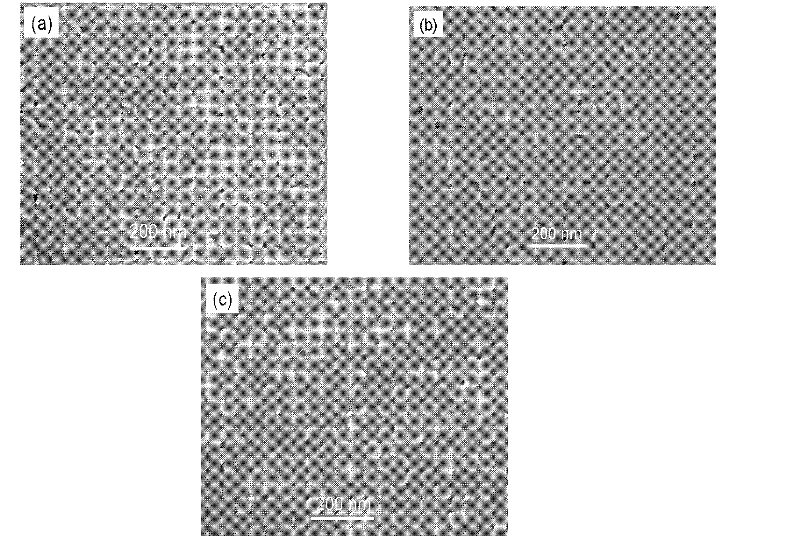

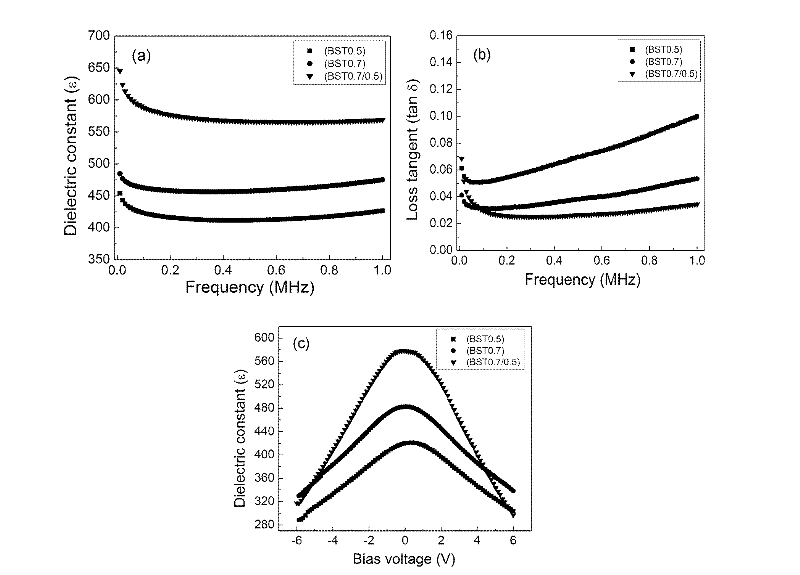

[0028] Barium strontium titanate (Ba 0.7 Sr 0.3 TiO 3 / Ba 0.5 Sr 0.5 TiO 3 ) 2 Preparation of multilayer films by chemical solution deposition:

[0029] First, clean the used utensils, soak the beaker, dropper, syringe, weighing bottle, and glass rod with 15% dilute nitric acid for 24 hours, then rinse with tap water, rinse with deionized water for several times, and then rinse with alcohol. Bake the cleaned utensils at 50° C. for 2 hours before use.

[0030] 1. Ba 0.5 Sr 0.5 TiO 3 Preparation of precursor colloid

[0031] Analytical pure barium acetate, strontium acetate and butyl titanate are used as solutes, and ethylene glycol methyl ether and acetylacetone are used as solvents;

[0032] (1) Weigh 0.0015 moles of barium acetate and 0.0015 moles of strontium acetate and add in a beaker filled with 5 milliliters of acetic acid, stir at 70°C until barium acetate and strontium acetate are completely dissolved;

[0033] (2) Weigh 0.003 mol of butyl titanate, add it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com