Urban and rural garbage fermentation liquid and preparation method thereof

A fermentation liquid and garbage technology, applied in the field of biochemistry, can solve problems such as harm to agricultural production and human life, affect the surrounding environment, and decrease soil organic matter, achieve environmental and ecological balance without adverse effects, regulate and promote plant growth, prevent The effect of plant poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

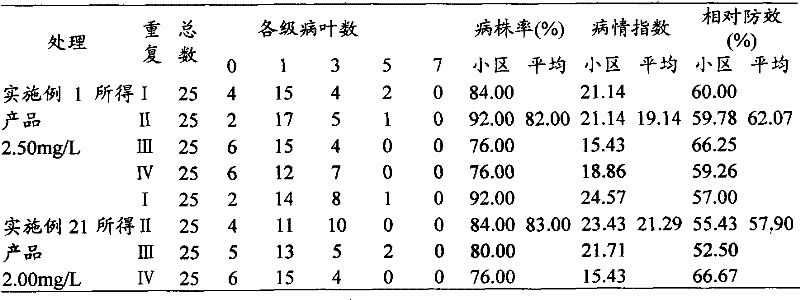

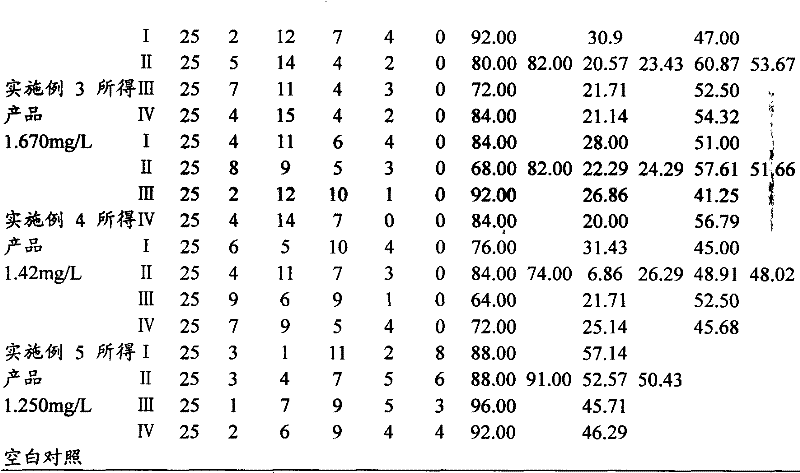

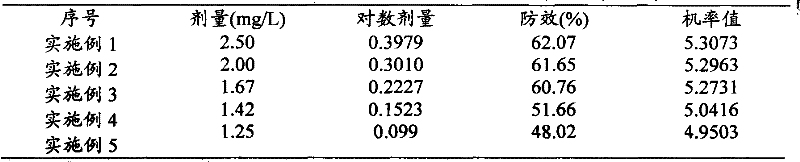

Examples

Embodiment 1

[0018] A method for preparing urban and rural garbage fermentation liquid, comprising the steps of:

[0019] (1) The preparation method of the EM solution is as follows: Mix Sporosporium thermophila, Phanerochaete chrysosporium, Lactobacillus bulgaricus and yeast in a ratio of 1:1:1:1 into 50ml, brown sugar 20-40g, rice vinegar Mix 100ml and 100ml of shochu (30°C) evenly, and incubate at 28-32°C for 5-7d to obtain 250ml of EM solution;

[0020] (2) The preparation method of the leavening agent is: large pieces such as rice straw, corn stalks, green grass, rice bran, etc. are shredded and the excrement with a water content of 30-40% is stirred evenly at a ratio of 1:10 and stacked for 5-7 days to obtain final product;

[0021] (3) The preparation method of the starter is: rice bran 14.5%, dry cake 14%, bean dregs 13%, brown sugar 8%, yeast powder 0.5-1%, water 50%, stir and heat to 25-45°C for hydrolysis, and concentrate to 55% by weight, get it after sterilization.

[0022] ...

Embodiment 2

[0024] A method for preparing urban and rural garbage fermentation liquid, comprising the steps of:

[0025] (1) The preparation method of the EM solution is as follows: Mix Sporosporium thermophila, Phanerochaete chrysosporium, Lactobacillus bulgaricus and yeast in a ratio of 1:1:1:1 into 50ml, brown sugar 20-40g, rice vinegar 100ml and 100ml of shochu (35 degrees) were mixed evenly, and cultured at 28-32°C for 5-7d to obtain 250ml of EM solution;

[0026] (2) The preparation method of the leavening agent is: large pieces such as rice straw, corn stalks, green grass, rice bran, etc. are shredded and the excrement with a water content of 30-40% is stirred evenly at a ratio of 1:10 and stacked for 5-7 days to obtain final product;

[0027] (3) The preparation method of the starter is: rice bran 14.5%, dry cake 14%, bean dregs 13%, brown sugar 8%, yeast powder 0.5-1%, water 50%, stir and heat to 25-45°C for hydrolysis, and concentrate to 55% by weight, get it after sterilizatio...

Embodiment 3

[0030] A method for preparing urban and rural garbage fermentation liquid, comprising the steps of:

[0031] (1) The preparation method of the EM solution is as follows: Mix Sporosporium thermophila, Phanerochaete chrysosporium, Lactobacillus bulgaricus and yeast in a ratio of 1:1:1:1 into 50ml, brown sugar 20-40g, rice vinegar 100ml and 100ml of shochu (35 degrees) were mixed evenly, and cultured at 28-32°C for 5-7d to obtain 250ml of EM solution;

[0032] (2) The preparation method of the leavening agent is: large pieces such as rice straw, corn stalks, green grass, rice bran, etc. are shredded and the excrement with a water content of 30-40% is stirred evenly at a ratio of 1:10 and stacked for 5-7 days to obtain final product;

[0033] (3) The preparation method of the starter is: rice bran 14.5%, dry cake 14%, bean dregs 13%, brown sugar 8%, yeast powder 0.5-1%, water 50%, stir and heat to 25-45°C for hydrolysis, and concentrate to 55% by weight, get it after sterilizatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com