Synthesizing method for separated and purified special resin for assembled flavone of rhizome drynaria

A separation, purification and synthesis method technology, applied in chemical instruments and methods, alkali metal compounds, inorganic chemistry, etc., can solve the problems of poor selectivity and rapid decline in adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

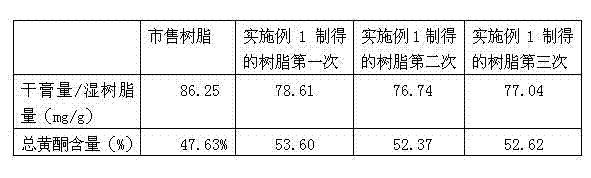

Examples

Embodiment 1

[0020] (1) Take 55g of industrial divinylbenzene, 40g of methyl acrylate, 5g of GMA, and 1g of benzoyl peroxide and mix them evenly, add 55g of toluene and 55g of liquid paraffin, and mix the above-mentioned substances evenly at room temperature to obtain an oil phase.

[0021] (2) Add 55g of 0.2% polyvinyl alcohol and 137g of 0.5% gelatin to 547g of 2.5% sodium chloride aqueous solution as the water phase, and heat to 50°C in a water bath.

[0022] (3) Add the oil phase to the water phase, start the agitator, control the stirring speed, disperse the oil phase and control the particle size of the oil beads at 60 mesh, raise the temperature to 69°C at a constant speed for 1 hour and keep it for 2 hours to shape, and then use Heat at a constant speed of 1 hour to 78°C for 4 hours, then heat at a constant speed of 0.75 hours to 85°C for 2 hours, and finally heat at a constant speed of 0.5 hours to 91°C for 12 hours to complete the polymerization and obtain a crude resin product. ...

Embodiment 2

[0029] (1) Take 55g of industrial divinylbenzene, 40g of methyl acrylate, 5g of GMA, and 1g of benzoyl peroxide and mix them evenly, add 55g of toluene and 55g of liquid paraffin, and mix the above-mentioned substances evenly at room temperature to obtain an oil phase.

[0030] (2) Add 47g of 0.2% polyvinyl alcohol and 118g of 0.5% gelatin to 469g of 2.5% sodium chloride aqueous solution as the water phase, and heat to 45°C in a water bath.

[0031] (3) Add the oil phase to the water phase, start the agitator, control the stirring speed, disperse the oil phase and control the particle size of the oil beads at 20 mesh, raise the temperature to 67°C for 1.5 hours at a constant speed for 0.5 hours to set the shape, and then use Raise the temperature at a constant speed of 0.5 hours to 76°C for 3 hours, then heat at a constant speed of 0.25 hours to 83°C for 1.5 hours, and finally raise the temperature to 89°C for 10 hours at a constant speed of 0.2 hours to complete the polymeriza...

Embodiment 3

[0038] (1) Take 55g of industrial divinylbenzene, 40g of methyl acrylate, 5g of GMA, and 1g of benzoyl peroxide and mix them evenly, add 55g of toluene and 55g of liquid paraffin, and mix the above-mentioned substances evenly at room temperature to obtain an oil phase.

[0039] (2) Add 55g of 0.2% polyvinyl alcohol and 137g of 0.5% gelatin to 547g of 2.5% sodium chloride aqueous solution as the water phase, and heat to 55°C in a water bath.

[0040] (3) Add the oil phase to the water phase, start the agitator, control the stirring speed, disperse the oil phase and control the particle size of the oil beads at 60 mesh, raise the temperature to 69°C at a constant speed for 1 hour and keep it for 2.5 hours to set the shape, and then use Heat at a constant speed of 1 hour to 78°C for 5 hours, then heat at a constant speed of 0.75 hours to 85°C for 2.5 hours, and finally heat at a constant speed of 0.5 hours to 91°C for 14 hours to complete the polymerization and obtain a crude resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com