Microbe starter culture for producing conjugated linoleic acid and preparation method thereof

A microbial starter, conjugated linoleic acid technology, applied in the field of bioengineering, can solve problems such as mild reaction conditions, single isomer composition, and safety doubts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

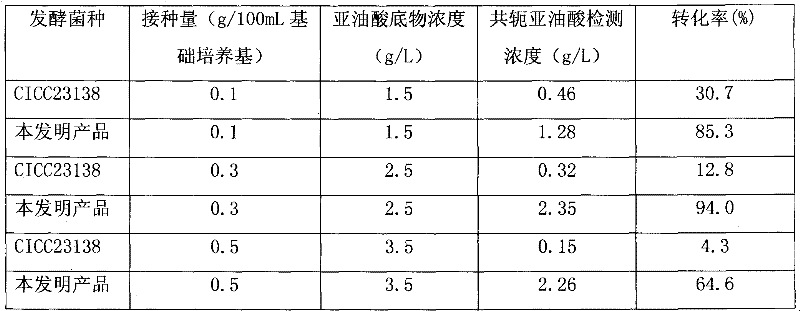

Examples

Embodiment Construction

[0025] Below in conjunction with specific embodiment the present invention is described in more detail:

[0026] Product of the present invention adopts such method to prepare:

[0027] 1. Selection of fermentation strains and preparation of medium

[0028] The present invention selects Lactobacillus plantarum CICC23138, purchased from China Industrial Microorganism Culture Collection Center.

[0029] The basic medium of Lactobacillus plantarum is: peptone 10.0g, beef extract 10.0g, yeast extract 5.0g, glucose 20.0g, anhydrous sodium acetate 5.0g, triamine citrate 2.0g, Tween-801.0mL, dihydrogen phosphate Potassium 2.0g, magnesium sulfate 0.02g, manganese sulfate 0.05g, distilled water 1.0L, pH 6.0-6.5, sterilized at 121°C for 20min.

[0030] 2. The preparation process of starter

[0031] 2.1 Activation of the starting strain

[0032] Measure 0.9% normal saline into 10ml test tubes, sterilize at 121°C for 20 minutes and cool to 30°C, then pour all the freeze-dried bacteria...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com