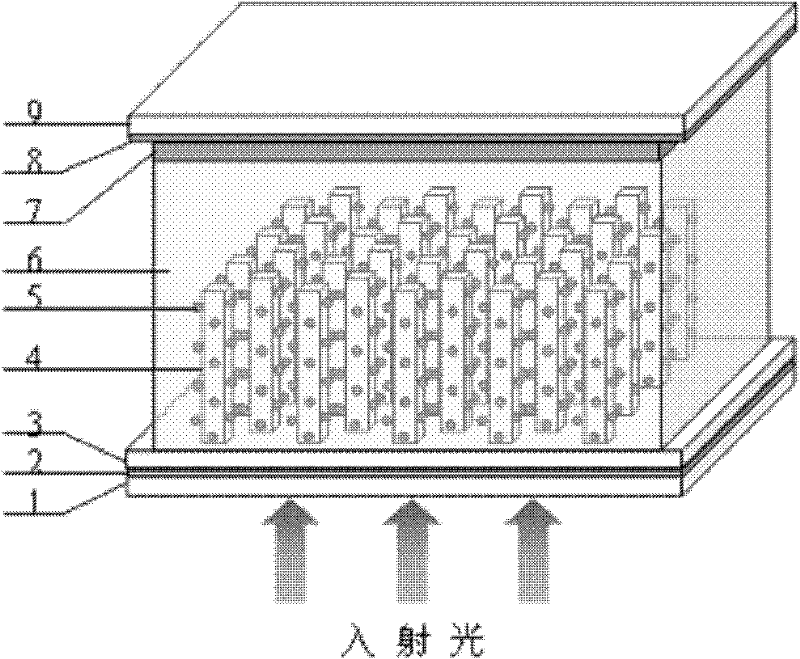

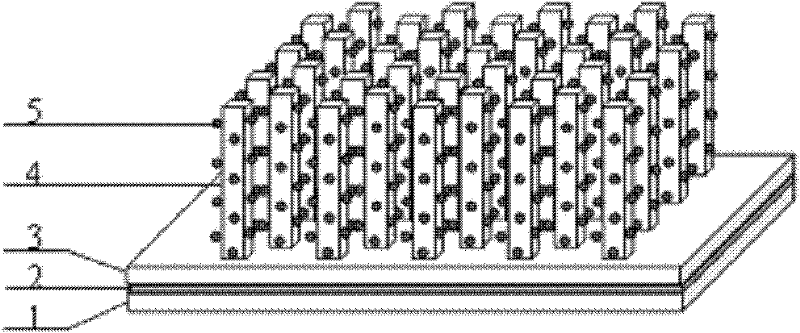

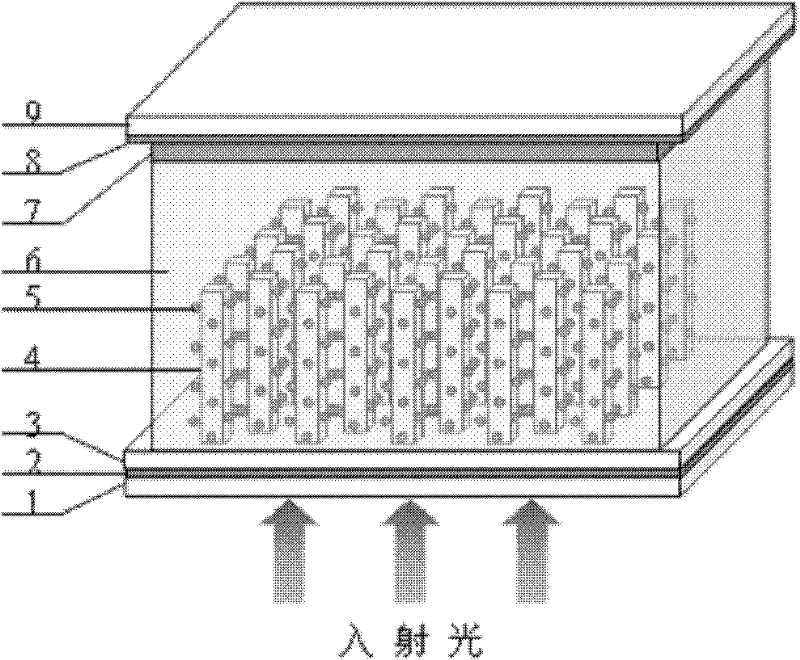

Flexible Dye-sensitized Solar Cells (DSSCs) based on titanium dioxide nanometer rod array film and preparation method thereof

A nanorod array and dye sensitization technology is applied in the preparation of flexible dye-sensitized solar cells and the preparation of flexible quasi-one-dimensional photoanode. , easy to carry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Prepare a dense layer of TiO with a thickness of about 200nm on the conductive surface of the ITO / PEN flexible conductive substrate by pulsed laser deposition method 2 nanoparticle film, as a seed layer;

[0026] (2) Take 50 g of ice-water mixture prepared by deionized water, and stir 1.90 g of TiCl with a purity of 99% while stirring with a magnetic stirrer 4 Drop by drop into the ice-water mixture to get 0.2mol / L TiCl 4 solution;

[0027] (3) Add 3mol / L ammonia water dropwise to the prepared TiCl in step (2) while stirring 4 In the solution, until the pH value is 8.0, a suspension is formed;

[0028] (4) Centrifuge the obtained suspension at a speed of 4000 rpm and centrifuge for 20 minutes, stir and wash the precipitate obtained by centrifugation with deionized water for 10 minutes, and repeat the centrifugation and cleaning operations 6 times.

[0029] (5) Add the obtained white precipitate into 45 g of deionized water and stir evenly, then add 5 ml of hydro...

Embodiment 2

[0034] (1) Apply a layer of peroxotitanic acid sol on the cleaned ITO / PEN flexible conductive substrate by dipping-pulling method, the pulling speed is 5cm / min, and then sinter at 150°C for 30 minutes, repeat coating, Sintering operation 2 times;

[0035] (2) get 1.72g purity and be 93% TiOSO 4 and 50ml deionized water to prepare 0.2mol / L TiOSO 4 aqueous solution;

[0036] (3) Add 3mol / L ammonia water drop by drop to the TiOSO prepared in step (2) while stirring. 4 In the aqueous solution, until the pH value is 7.5, stop dripping ammonia water to form a suspension;

[0037] (4) The obtained suspension is separated by suction filtration, and the precipitate obtained by suction filtration is stirred and washed with deionized water, and the suction filtration and washing operations are repeated 6 times;

[0038] (5) Add the white precipitate obtained after adding 50ml of deionized water and stir evenly, then add 4.5ml of hydrogen peroxide with a concentration of 30%, and stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com