FRP (fiber reinforced plastic) rib preparation method and FRP rib prepared thereby

A rib, pre-forming technology, applied in the preparation of thermoplastic resin FRP rib, FRP rib field, can solve the problems of high production cost, high energy consumption, high equipment requirements, achieve low production cost, low resin high temperature degradation rate, molding simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A preparation method for FRP bars, using thermoplastic resin fibers 2 and inorganic reinforcing fibers 1 as raw materials, comprising the following steps:

[0030] A. Drying: The thermoplastic resin fiber 2 is dried to reduce its water content to below 40ppm. The best drying condition is to dry the thermoplastic resin fiber 2 under a vacuum condition with a temperature of 115-160°C. Avoid bubbles when the fibers are melted at high temperature, and better ensure the performance of FRP bars.

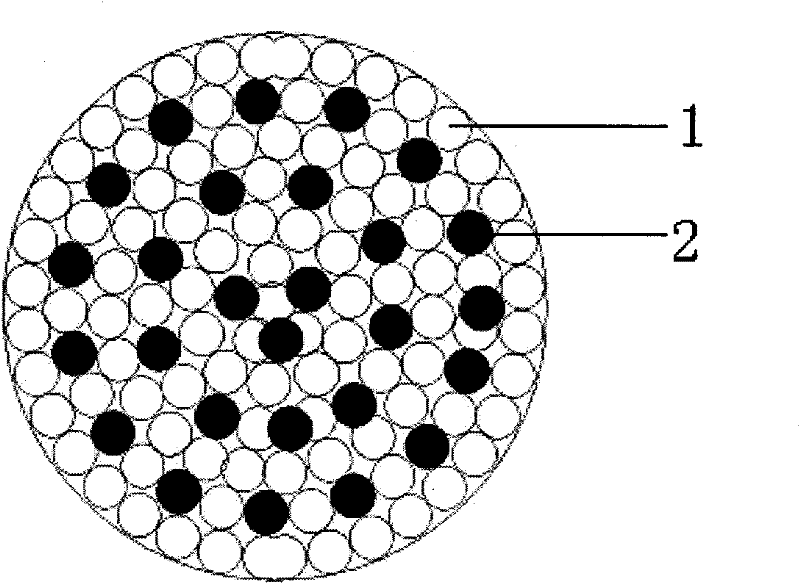

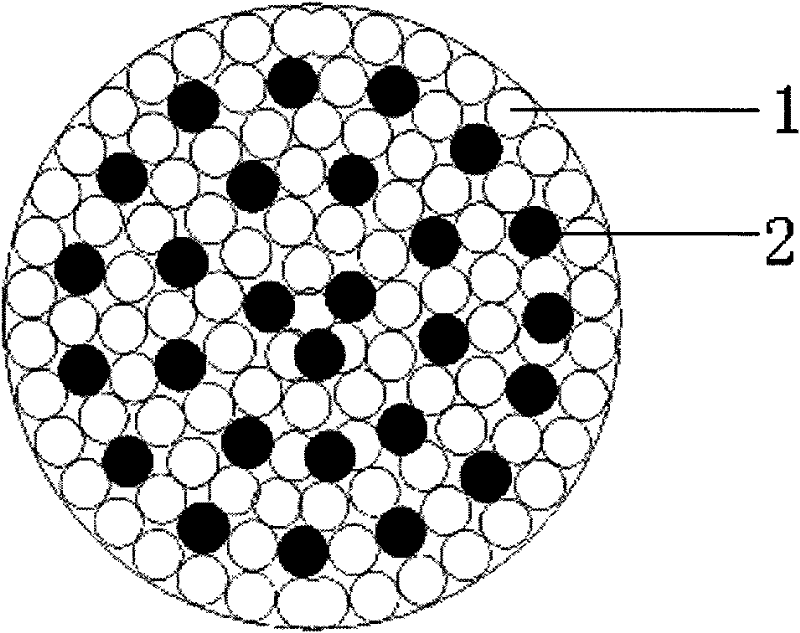

[0031] B. Bundling: The dried thermoplastic resin fibers 2 and inorganic reinforcing fibers 1 are uniformly bundled at cross intervals to better bond the thermoplastic resin fibers 2 and inorganic reinforcing fibers 1, so as to enhance the durability and strength of the FRP bars and other performance.

[0032] C. Winding: The bundled fiber bundles are wound through monofilament fibers to form a thread structure. On the one hand, it can ensure the shape of the FRP tendon, and on the...

Embodiment 1

[0045] The thermoplastic resin fiber 2 in this embodiment is PP fiber, that is, polypropylene fiber, and the inorganic reinforcing fiber 1 is glass fiber. Firstly, the polypropylene fiber is vacuum-dried at 115° C. for 12 hours to reduce its water content to below 40 ppm, wherein the content of the polypropylene fiber is 10% of the total weight of the raw material.

[0046] Bundle the dried polypropylene fibers and glass fibers in a crossed and evenly spaced manner to ensure that the polypropylene fibers are evenly distributed in the FRP tendon body. The diameter of the prepared FRP tendon rod is 16mm; The silk fiber is wound to form a thread structure on the surface of the FRP tendon; the FRP tendon is pulled into the pre-forming drying tunnel by the drafting machine, and the FRP tendon passes through the pre-forming preheating zone, extrusion zone, and pre-forming zone in sequence. The temperatures are 165°C, 170°C, and 175°C respectively, and the time for the FRP bars to st...

Embodiment 2

[0049] In this embodiment, the thermoplastic resin fiber 2 is polyester (polyester) fiber, and the inorganic reinforcing fiber 1 is glass fiber. First, vacuum-dry the polyester fiber at 140° C. for 12 hours to reduce the water content to below 40 ppm, wherein the content of the polyester fiber is 15% of the total weight of the raw material.

[0050] Bundle the dried polyester fibers and glass fibers in a crossed and evenly spaced manner to ensure that the polyester fibers are evenly distributed in the FRP bar body, and the diameter of the prepared FRP bars is 20mm; the bundled fiber bundles are made of high-strength monofilament Filament winding forms a thread structure on the surface of the FRP tendons; the FRP tendons are drawn into the pre-forming drying tunnel by a drafting machine, and the FRP tendons pass through the pre-forming preheating zone, extrusion zone, and pre-forming zone in sequence. The temperature of each zone They are 240°C, 250°C, and 260°C respectively, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com