Combined process method for processing heavy oil

A combined process and heavy oil technology, which is applied in the petroleum industry and hydrocarbon oil treatment, can solve problems such as hydrogenation catalyst pollution, impractical refinery, bed blockage, etc., achieve raw material improvement, avoid vicious competition, and extract resistance Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

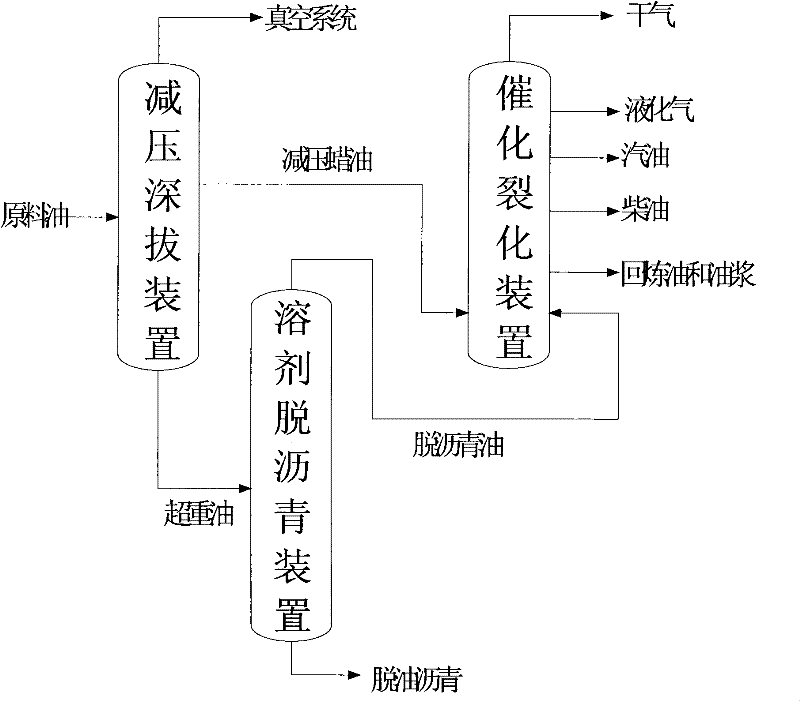

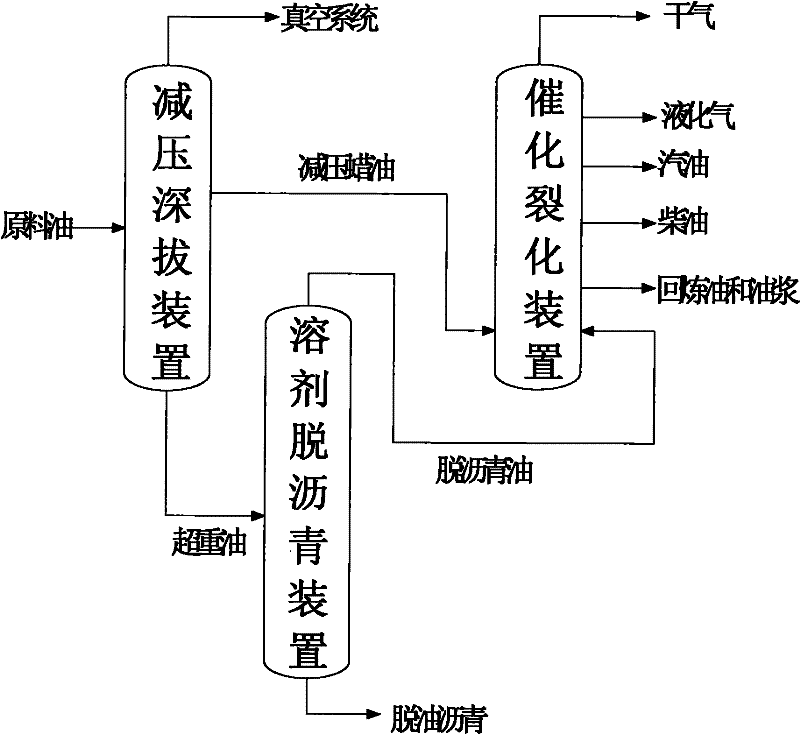

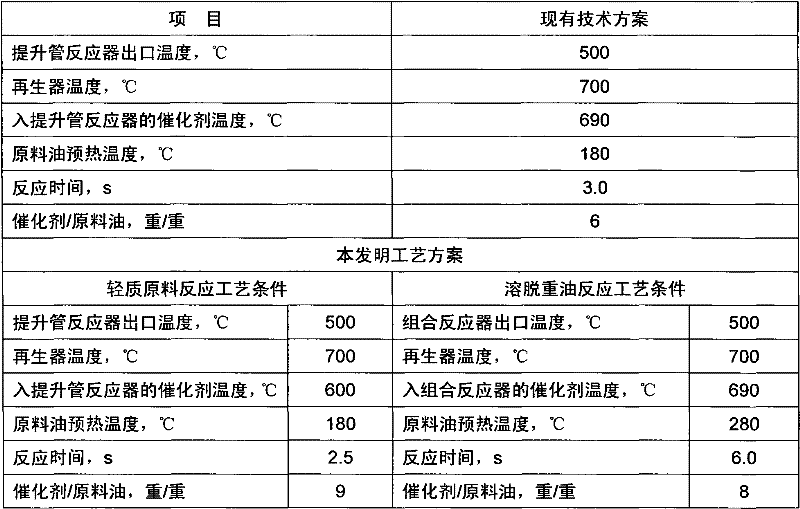

[0025]The raw material oil enters the vacuum deep-drawing device, and one or more streams of decompression wax oil are extracted from the side line of the vacuum deep-drawing device, and the super-heavy residue is extracted from the bottom of the tower. The super-heavy residual oil enters the solvent deasphalting unit, and the deoiled bitumen is extracted from the unit for other post-processing; while the deasphalted oil and the vacuum wax oil extracted from the vacuum deep drawing unit respectively enter different reaction sections of the reaction part of the catalytic cracking unit / zone or reactor, each processed under suitable process conditions. After the oil product is processed in the reaction part of the catalytic cracking unit, it enters the separation part of the catalytic cracking unit and is separated into dry gas, liquefied gas, gasoline and diesel oil and other products; the separated re-refined oil and part or all of the oil slurry can be returned to the catalyt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com