Avalanche photodiode for ultraviolet detection as well as manufacturing method and working procedure thereof

An avalanche photoelectric and diode technology, applied in circuits, electrical components, semiconductor devices, etc., to achieve the effects of improving stability, saving manufacturing costs, and being easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

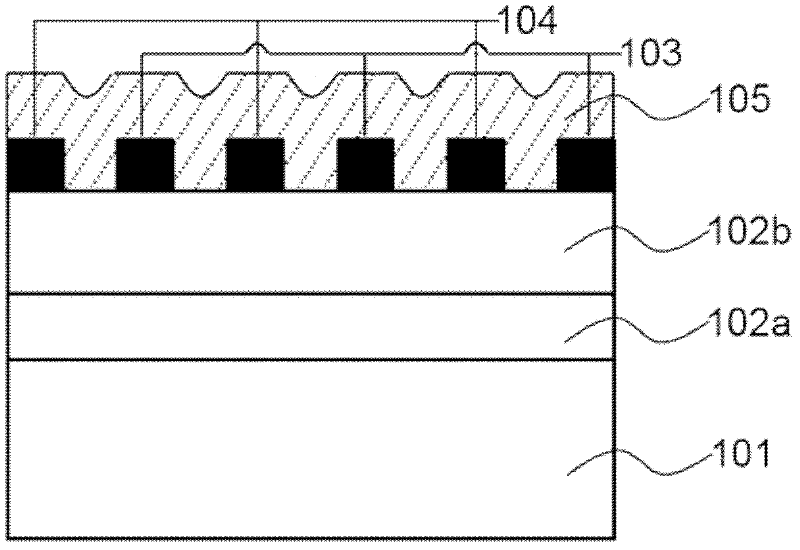

[0042] The preparation method of the above-mentioned metal-semiconductor-metal MSM planar structure wide bandgap semiconductor ultraviolet avalanche photodiode comprises the following steps:

[0043] 1) Epitaxially grow the epitaxial layer of the epitaxially grown ultraviolet avalanche photodiode wafer on the homogeneous or heterogeneous substrate, the epitaxial layer structure includes buffer layer 102a, wide bandgap semiconductor light absorption layer 102b on the substrate from bottom to top, wide The bandgap semiconductor light-absorbing layer 102b can be a single-layer film or a multilayer film, and its basic feature is that the wide-bandgap semiconductor light-absorbing layer 102b has a bandgap width greater than 2.5eV, and a carrier concentration of less than 1×10 18 cm -3 The wide bandgap semiconductor material has a thickness between 50nm and 1mm. Typical wide bandgap semiconductors include GaN, AlN, ZnO, SiC, diamond, and ternary or quaternary alloy materials thereo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bandgap width | aaaaa | aaaaa |

| Carrier concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com