Dinotefuran aqueous suspension agent and its preparation method

A technology of water suspension agent and dinotefuran, applied in the field of pesticides, can solve the problems of solidification, stability over time, layering, inability to use, etc., and achieves the effects of broad application prospects, widening applicable uses, and easy use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

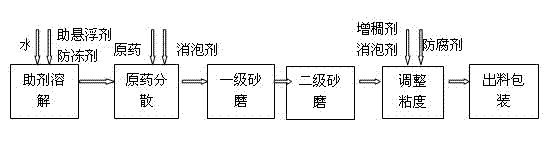

Image

Examples

Embodiment 1

[0028] Dinotefuran aqueous suspension, the formula (parts by weight) is: 10 parts of dinotefuran technical, 4 parts of 600P, 1 part of NP, 1 part of aluminum magnesium silicate, 0.2 part of thickener xanthan gum, 5 parts of B Diol, 0.2 parts of silicone defoamer, 0.2 parts of benzoic acid, water to make up 100 parts.

[0029] Add water into the shearing kettle, under shearing, gradually add surfactant and antifreeze, the shearing dissolves completely; first control the temperature 40 ℃ ~ 100 ℃, preheat the surfactant; under shearing, divide into 2 or more batches Add dinotefuran technical, and then add half of the amount of defoamer after completion; when the content of dinotefuran technical is less than 10% or the viscosity is less than 200mpa.s, a thickener can be added, which may increase the grinding time; After uniform shearing, enter the primary sand mill and secondary sand mill for sand grinding until the particle size of the dispersed original drug reaches the design r...

Embodiment 2

[0031] Dinotefuran aqueous suspension, the formula (parts by weight) is: 15 parts of dinotefuran technical, 2 parts of 500#, 3 parts of LX, 5 parts of white carbon black, 0.2 parts of polyvinyl alcohol, 5 parts of urea, 0.2 parts Silicone defoamer, 0.2 parts of benzoic acid, water to make up 100 parts.

[0032] The above formula is prepared according to the method of Example 1.

Embodiment 3

[0034] Dinotefuran aqueous suspension, the formula (parts by weight) is: 25 parts of dinotefuran technical, 3 parts of 600P, 2 parts of polycarboxylate, 2 parts of bentonite, 0.2 part of thickener xanthan gum, 5 parts of antifreeze Agent glycerin, 0.2 parts of antifoaming agent tributyl phosphate, 0.2 parts of Kathon, and water make up 100 parts.

[0035] The above formula is prepared according to the method of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com