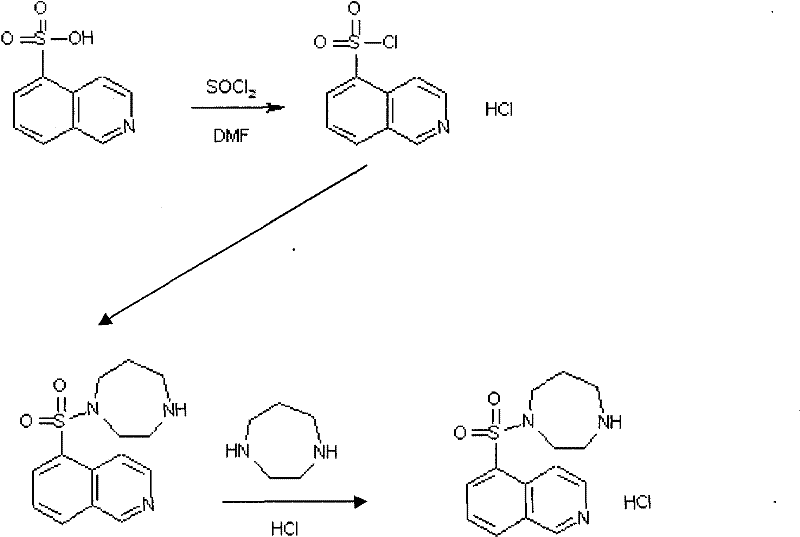

Preparation method of fasudil hydrochloride

A technology for fasudil hydrochloride and isoquinoline sulfonyl chloride hydrochloride, which is applied in the field of preparation of fasudil hydrochloride, can solve the problems of poor color, high solubility, large consumption and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] One, the preparation of 5-isoquinolinesulfonyl chloride hydrochloride

[0034] Under stirring, put 1kg of 5-isoquinolinesulfonic acid in a 10L reaction tank, add 8.19kg of thionyl chloride and 40g of DMF to heat, stir and reflux at 75-80°C for 3h, then distill off the thionyl chloride under reduced pressure . After cooling, add 4kg of dichloromethane, filter, wash the precipitate twice with dichloromethane (2.7kg×2), and drain it to obtain the obtained product.

[0035] Two, the preparation of 1-(5-isoquinolinesulfonyl) homopiperazine

[0036] Under agitation, place 1.14kg of 5-isoquinolinesulfonyl chloride hydrochloride, which was converted into pure after the determination of moisture by the Karl-Fisher method, in a 50L reaction tank, add 10kg of purified water and 13.3kg of dichloromethane, and place in an ice bath Cool down to 0°C, add sodium bicarbonate to adjust the pH to 6, then add 13.3 kg of dichloromethane, and separate layers. Separate the 5-isoquinolinesu...

Embodiment 2

[0042] One, the preparation method of 5-isoquinolinesulfonyl chloride hydrochloride is the same as above.

[0043] Two, the preparation of 1-(5-isoquinolinesulfonyl) homopiperazine

[0044]Dissolve 57g of the above 5-isoquinolinesulfonyl chloride hydrochloride in 500ml of purified water, stir in an ice bath and cool down to 0°C, add sodium bicarbonate to adjust the pH to 6, add 1000ml of dichloromethane, and separate layers. Separate the solution of 5-isoquinolinesulfonyl chloride in dichloromethane and add it dropwise to 500ml of dichloromethane containing 52g of homopiperazine for 20 minutes. The temperature was maintained at 15-20°C for 2 hours. After the reaction was completed, water was added to wash twice (300ml×2). 1N hydrochloric acid solution was added dropwise to the dichloromethane phase to adjust the pH to 5-6, and the acidic aqueous layer was separated. Add 250ml of purified water to the lower layer and extract once more, and combine the acid aqueous layer solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com