In-situ nano TiC ceramic particle reinforced copper based composite material and preparation method thereof

A technology of ceramic particles and composite materials, applied in the field of new in-situ nano-TiC ceramic particles reinforced copper or copper alloy matrix composite materials and its preparation, to achieve the effect of pure surface, less impurity content and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

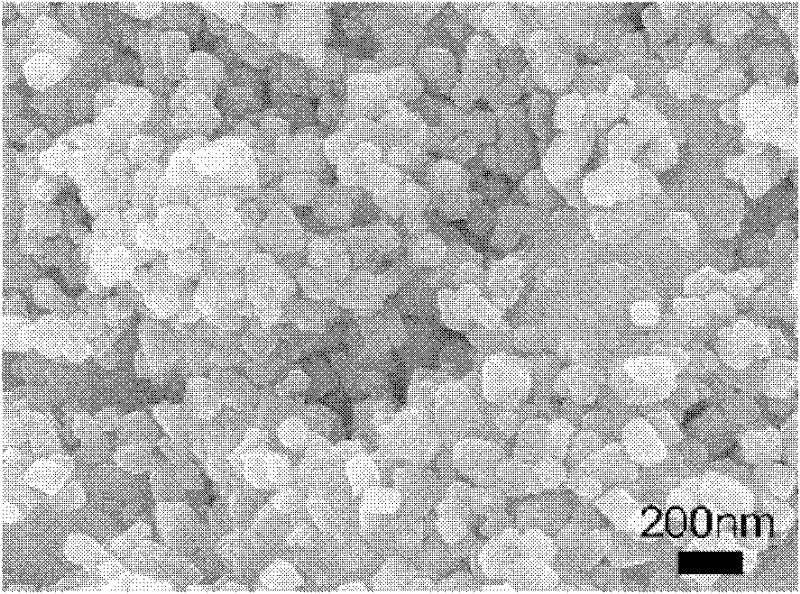

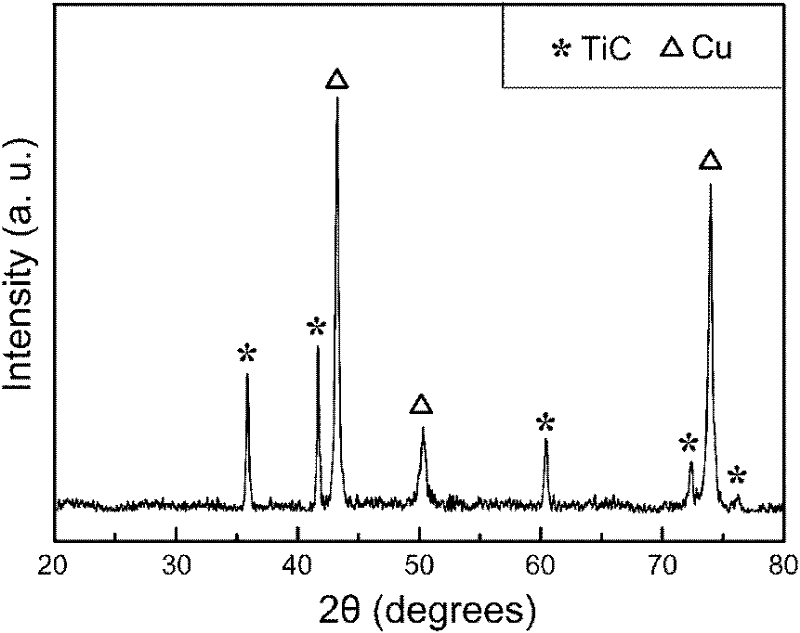

[0032] A copper-based composite material reinforced with nano-TiC ceramic particles is prepared, which is composed of TiC28 and Cu72 according to weight percentage.

[0033] Take Cu powder, Ti powder and carbon nanotube ingredients. Wherein, the ratio of Cu powder, Ti powder and carbon nanotubes is 72.0:22.4:5.6 by weight. The prepared powder is mixed in a roller ball mill for 6-8 hours, and then the mixed powder is hand-mixed in a mortar for 15-20 minutes to make the powder evenly mixed. Take the properly mixed powder and put it into the mold, and press it at room temperature to form a cylindrical reaction prefabricated block with a diameter of 28±0.5 mm and a height of 40-50 mm. The density of the prefabricated block is 70±5.0 of the theoretical density of the mixed powder. %. Put the prefabricated block into the graphite mold, and then put a high-strength graphite pressure rod on the upper part of the prefabricated block. Put the graphite mold with the prefabricated bloc...

Embodiment 2

[0035] The nano-TiC ceramic particle reinforced copper matrix composite material composed of TiC24 and Cu76 by weight percentage was prepared.

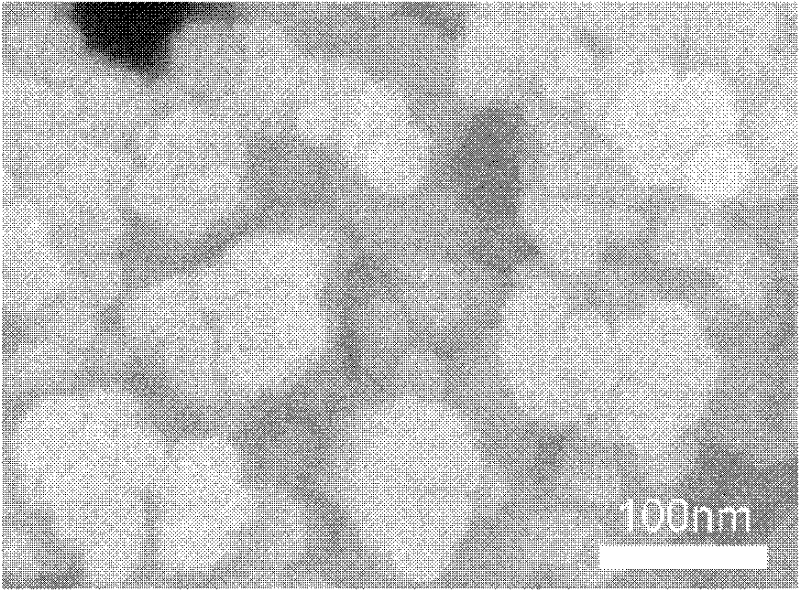

[0036] Take Cu powder, Ti powder, and carbon nanotubes as ingredients. Wherein, the ratio of Cu powder, Ti powder and carbon nanotube is 76.0:19.2:4.8 by weight. Its preparation method is with embodiment 1. X-ray results showed that the product was pure, while field emission results showed that the TiC particles produced therein had a size of about 90 nm.

Embodiment 3

[0038] A nano-TiC ceramic particle reinforced copper alloy matrix composite material composed of TiC20 and Cu-0.1Zr alloy matrix 80 is prepared according to weight percentage.

[0039] Take Cu powder, Ti powder, Zr powder, and carbon nanotubes as ingredients. Wherein, the ratio of Cu powder, Zr powder, Ti powder and carbon nanotubes is 79.92:0.08:16.0:4.0 by weight. Its preparation method is with embodiment 1. X-ray results showed that the product was pure, while field emission results showed that the TiC particles formed therein were about 70 nm in size.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com