A kind of anti-ultraviolet microsphere, preparation method and application

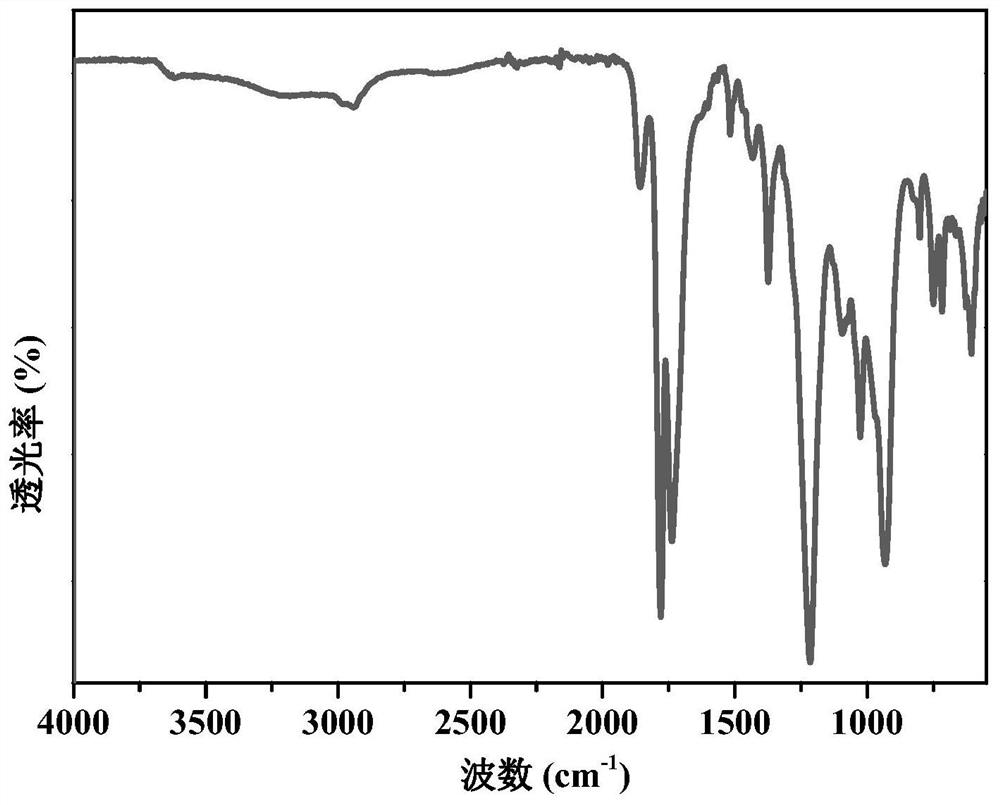

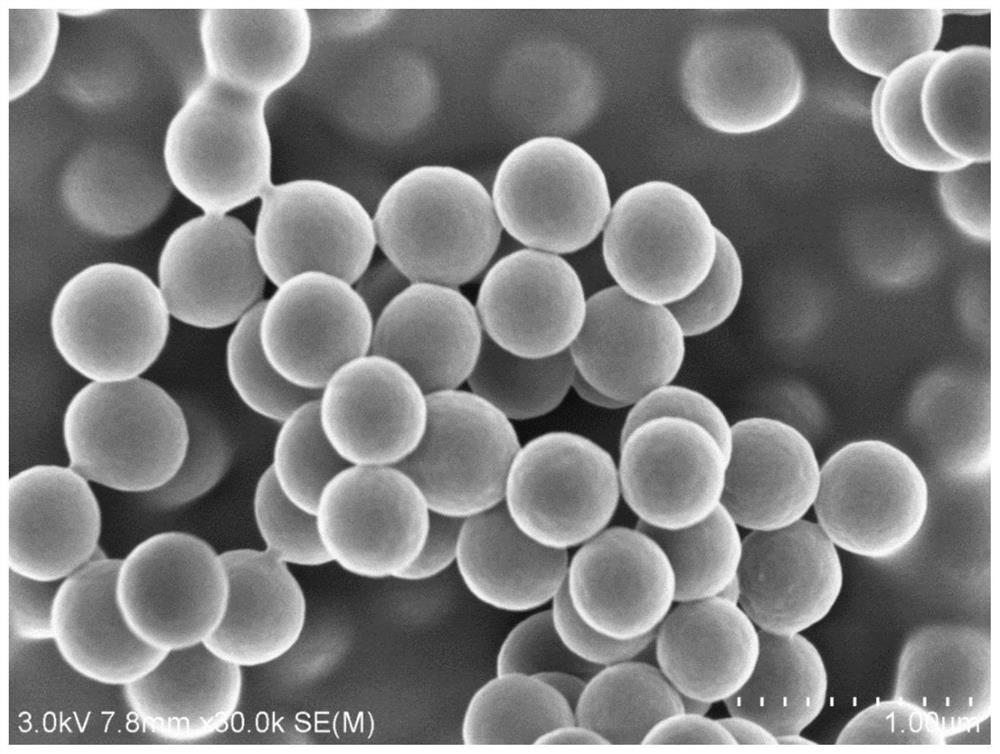

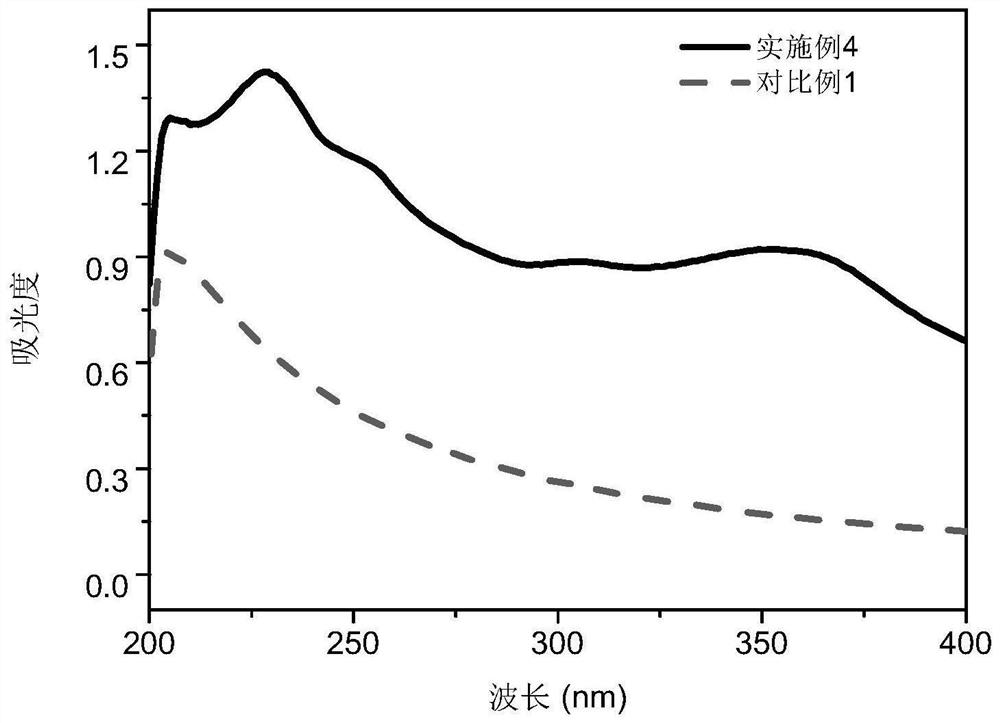

An anti-ultraviolet and microsphere technology, applied in the field of polymer materials, to achieve the effect of uniform particle size, simple operation and pure surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] With ethyl benzoate as the solvent of the reaction system, vinyl acetate 1.72g, maleic anhydride 1.86g, 2-[2-hydroxyl-5-[2-(methacryloyloxy)ethyl]phenyl]- 0.32g of 2H-benzotriazole and 0.039g of initiator azobisisobutyronitrile were dissolved in 40mL of ethyl benzoate, and ultrasonically dissolved to fully mix them evenly. In the reaction system, vinyl acetate, maleic anhydride and 2 -[2-Hydroxy-5-[2-(methacryloyloxy)ethyl]phenyl]-2H-benzotriazole molar ratio is 100:95:5, the amount of initiator is the total monomer The mass is 1wt%, the total monomer concentration is 1mol / L; the system is ventilated with nitrogen for 30 minutes, the reaction temperature is 75°C, and the reaction time is 8 hours. After the reaction is completed, the reaction product is centrifuged at 12000 rpm for 10 minutes, and petroleum ether is added After washing and centrifuging for three times, and vacuum drying to constant weight, Microsphere 1 was obtained, and the particle diameters are listed...

Embodiment 2

[0035]With xylene as the solvent of the reaction system, 1.72 g of vinyl acetate, 1.86 g of maleic anhydride, 2-[2-hydroxyl-5-[2-(methacryloyloxy)ethyl]phenyl]-2H- Benzotriazole 0.32g, initiator azobisisobutyronitrile 0.039g were dissolved in 40mL of xylene, and ultrasonically dissolved to fully mix them evenly. In the reaction system, vinyl acetate, maleic anhydride and 2-[2- The molar ratio of hydroxy-5-[2-(methacryloyloxy)ethyl]phenyl]-2H-benzotriazole is 100:95:5, and the amount of initiator is 1 wt% of the total mass of monomers, The total monomer concentration is 1mol / L; the system is ventilated with nitrogen for 30 minutes, the reaction temperature is 75°C, and the reaction time is 8 hours. After the reaction is completed, the reaction product is centrifuged at 12,000 rpm for 10 minutes, and petroleum ether is added to wash and centrifuge three times. , and vacuum-dried to constant weight to obtain microspheres 2, the particle diameters of which are listed in Table 1. ...

Embodiment 3

[0037] With ethyl benzoate / n-heptane (volume ratio 9:1) as the solvent of the reaction system, vinyl acetate 1.72g, maleic anhydride 1.86g, 2-[2-hydroxyl-5-[2-(methyl Acryloyloxy)ethyl]phenyl]-2H-benzotriazole 0.32g, initiator azobisisobutyronitrile 0.039g were dissolved in 40mL solvent, ultrasonically dissolved to fully dissolve to mix evenly, vinyl acetate in the reaction system The molar ratio of ester, maleic anhydride and 2-[2-hydroxyl-5-[2-(methacryloyloxy)ethyl]phenyl]-2H-benzotriazole is 100:95:5, The amount of initiator used is 1 wt% of the total monomer mass, and the total monomer concentration is 1mol / L; the system is ventilated with nitrogen for 30 minutes, the reaction temperature is 75°C, and the reaction time is 8 hours. After the reaction is completed, the reaction product is centrifuged at a speed of 12,000 rpm After separation for 10 min, petroleum ether was added to wash, centrifuged three times, and vacuum-dried to constant weight to obtain microspheres 3, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com