System and process for recovering pure hydrogen and liquid HCl through polysilicon tail gas treatment

A tail gas treatment and polysilicon technology, applied in hydrogen separation, chemical industry, halogenated silane, etc., can solve problems such as inability to balance condensation temperature and reboiling temperature, large temperature difference in rectification tower, change of operating pressure, etc., to eliminate equipment safety Hidden dangers in operation, saving resources, and reducing the effect of axial temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

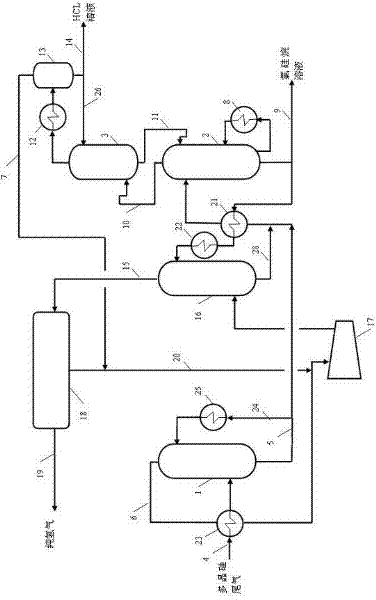

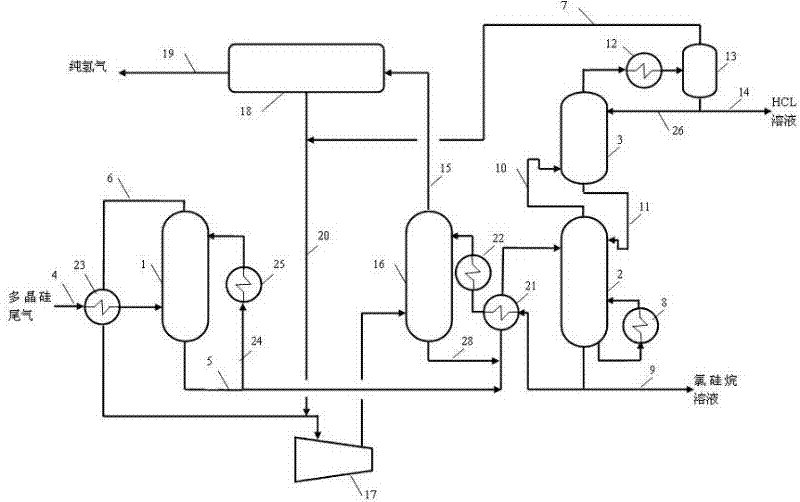

[0036] Such as figure 1Shown, the present invention comprises tail gas circulation condensation washing tower 1, chlorosilane stripping tower 2 and HCL rectifying tower 3 and crude hydrogen washing tower 16, and the bottom of tail gas circulation condensation washing tower 1 is equipped with polysilicon tail gas inlet pipe 4 and first Chlorosilane solution outlet pipe 5, the top of the tail gas circulation condensation scrubber 1 is equipped with the first hydrogen outlet pipe 6, and the first chlorosilane solution outlet pipe 5 is connected to the top of the chlorosilane stripping tower 2; The bottom of the tower 2 is equipped with a reboiler 8 and a second chlorosilane solution outlet pipe 9, and the top of the chlorosilane stripping tower 2 is equipped with a first HCL outlet pipe 10 and a stripping reflux pipe 11 connected to the bottom of the HCL rectification tower 3 The top of described HCL rectifying tower 3 is equipped with successively connected condenser 12, separat...

Embodiment 2

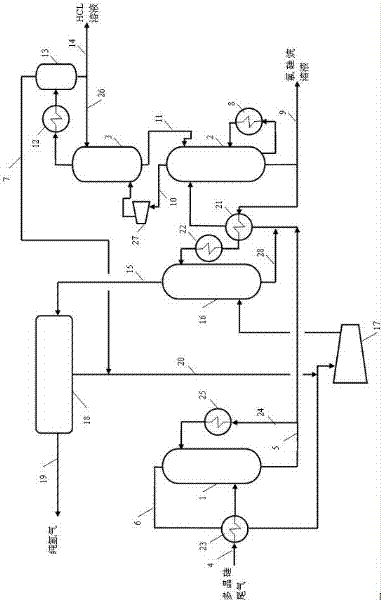

[0048] The difference between this embodiment and Embodiment 1 is that a supercharger 27 is arranged on the first HCL outlet pipe 10, and the operating pressure of the stripping tower and the rectifying tower is changed through the supercharger 27, thereby changing the original pressure. Certain reboiling and condensing temperatures reduce the axial temperature difference of the equipment and make the operation of the equipment safer. The relationship between operating pressure and operating temperature of the present invention is shown in Table 1.

[0049] Table 1 Correspondence between operating pressure and operating temperature

[0050]

[0051] After the operating pressure is changed in the present invention, the temperature gradient in the chlorosilane stripping tower 2 and the HCL rectifying tower 3 is more in line with the linear trend, thereby ensuring product purity, reducing equipment height, and reducing consumption. As shown in Table 2, HCL

[0052] There is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com