Preparation method of black titanium dioxide

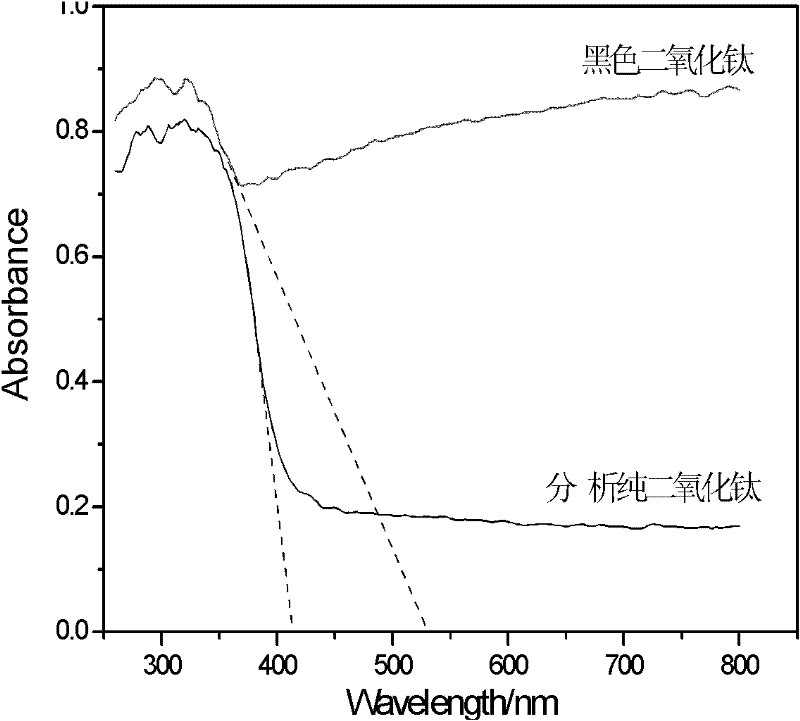

A technology of black titanium dioxide and butyl titanate, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problem of low utilization rate of solar energy, and achieve the effect of good ability to absorb sunlight, simple preparation process and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

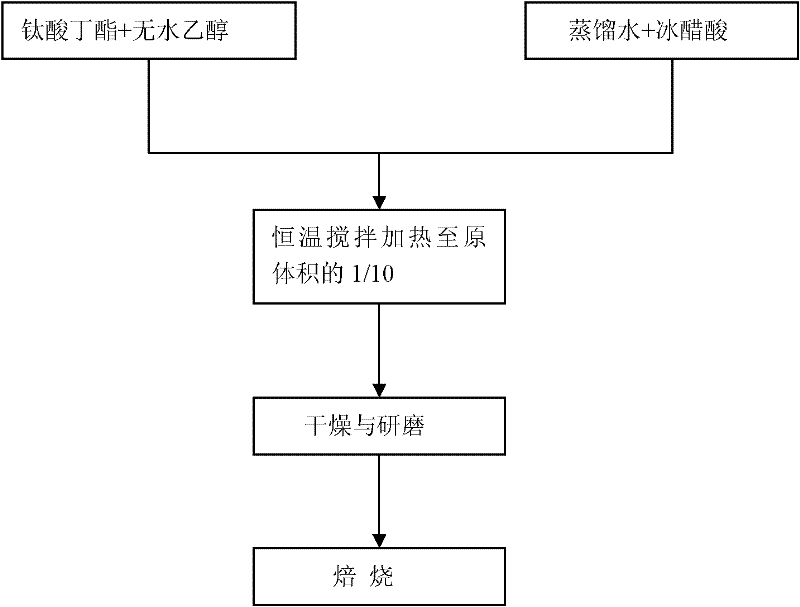

Method used

Image

Examples

Embodiment 1

[0035] This embodiment specifically includes the following steps:

[0036] 1) Prepare mixed system A by mixing butyl titanate and absolute ethanol at a volume ratio of 1:2;

[0037] 2) Prepare mixed system B with distilled water and glacial acetic acid at a volume ratio of 150:1;

[0038] 3) Add the mixed system A into the mixed system B under stirring, wherein the volume ratio of the mixed system A to the mixed system B is 1:0.5, continue to stir at room temperature for 2 hours, and let it stand overnight;

[0039] 4) Stir under constant temperature heating at 80°C until a gel is formed, then add glacial acetic acid at a volume ratio of 1:300, stir and wash thoroughly, dry the gel, bake at 100°C for 100 minutes, fully grind for 30 minutes, pass 200-mesh screen, under the protection of inert gas, heat preservation at 300°C for 3 hours, and cool to room temperature with the furnace to obtain black titanium dioxide powder.

Embodiment 2

[0041] This embodiment specifically includes the following steps:

[0042] 1) Prepare mixed system A by mixing butyl titanate and absolute ethanol at a volume ratio of 1:7;

[0043] 2) Prepare mixed system B with distilled water and glacial acetic acid at a volume ratio of 250:1;

[0044] 3) Add the mixed system A into the mixed system B under stirring, wherein the volume ratio of the mixed system A to the mixed system B is 1:2, continue to stir at room temperature for 2 hours, and then set aside overnight;

[0045] 4) Stir under constant temperature heating at 80°C until a gel is formed, then add glacial acetic acid at a volume ratio of 1:350, stir and wash thoroughly, dry the gel, bake at 130°C for 30 minutes, fully grind for 30 minutes, pass 200-mesh screen, under argon protection, heat preservation at 600°C for 1 hour, and cool to room temperature with the furnace to obtain black titanium dioxide powder.

Embodiment 3

[0047] This embodiment specifically includes the following steps:

[0048] 1) Prepare mixed system A by mixing butyl titanate and absolute ethanol at a volume ratio of 1:4;

[0049] 2) Distilled water and glacial acetic acid are prepared into mixed system B with a volume ratio of 180:1;

[0050] 3) Add the mixed system A into the mixed system B under stirring, wherein the volume ratio of the mixed system A to the mixed system B is 1:1.5, continue to stir at room temperature for 2 hours, and let it stand overnight;

[0051] 4) Stir under constant temperature heating at 80°C until a gel is formed, then add glacial acetic acid at a volume ratio of 1:350, stir and wash thoroughly, dry the gel, bake at 130°C for 60 minutes, fully grind for 20 minutes, pass 200-mesh screen, under the protection of nitrogen, keep warm at 500°C for 2 hours, and cool to room temperature with the furnace to obtain black titanium dioxide powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com