Method for treating total nitrogen in coal chemical wastewater by using microbes

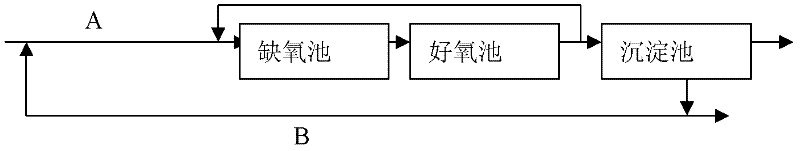

A technology for coal chemical wastewater and microbial treatment, applied in biological water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc., can solve the problem that the total nitrogen in the effluent cannot be effectively controlled, so as to reduce construction costs, The process flow is simple and the effect of improving the processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

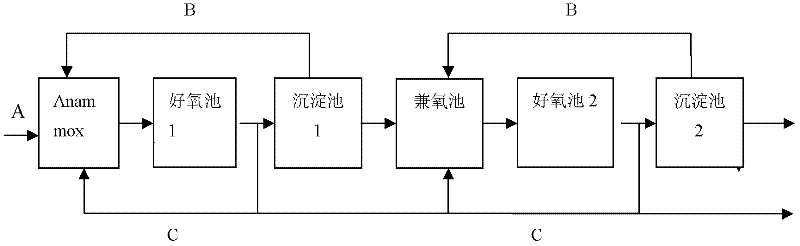

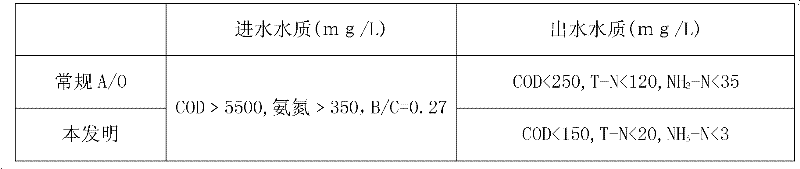

[0034] High-concentration nitrobenzene industrial wastewater with a flow rate of 100m 3 / h, its COD>5500mg / L, ammonia nitrogen>350mg / L, B / C=0.27. Under the condition of stirring, the wastewater and the anammox bacteria in the Anammox pool with activated carbon as the carrier undergo a biochemical reaction, degrade some harmful substances in the sewage, improve the biodegradability of the sewage, and simultaneously denitrify and anammox. nitrogen. In order to meet the needs of the biochemical reaction in the Anammox pool and provide the nutrient phosphorus source for the microorganisms, a phosphorus salt dosing pipeline is set up in the Anammox pool. Anammox pool running:

[0035] P: 4mg / l PH: 7.5 Water temperature: 30℃

[0036] The effluent from the Anammox tank enters the first aerobic tank for nitrification reaction, the effluent from the first aerobic tank enters the first sedimentation tank for mud-water separation, and the sludge returns to the Anammox tank, the sludge...

Embodiment 2

[0051] High-concentration coking wastewater, its COD is about 4500mg / L, ammonia nitrogen is about 350mg / L, volatile phenol is about 1800mg / L, and total cyanide is about 70mg / L. After the suspended solids and slag enter the Anammox pool, the Anammox pool uses the aeration device. Under the aeration mode, the wastewater and the anammox bacteria in the pool with activated carbon as the carrier undergo biochemical reactions, and the temperature is controlled at 15-40°C. pH value 6.5~9.0, dissolved oxygen 0.6~3.2mg / L, sludge sedimentation ratio SV 30 10%-25%, residence time 12-28 hours, influent COD index 1500-3500mg / L, effluent COD index 400-650mg / L, COD degradation efficiency 40%-75%. The various indexes affected by nitrification shall not exceed 50 mg / L; the wastewater from the Anammox pool enters the first aerobic pool. Other implementations are the same as in Embodiment 1.

[0052] As shown in Table 2, the effluent quality after treatment in this embodiment is: COD3 -N<3mg / L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com