Method for preparing polyurethane foam from curcas oil base rigid foam polyether

A technology of polyurethane foam and jatropha oil, applied in the field of molecular polymerization, can solve the problem of high price, and achieve the effects of low cost, good compatibility and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

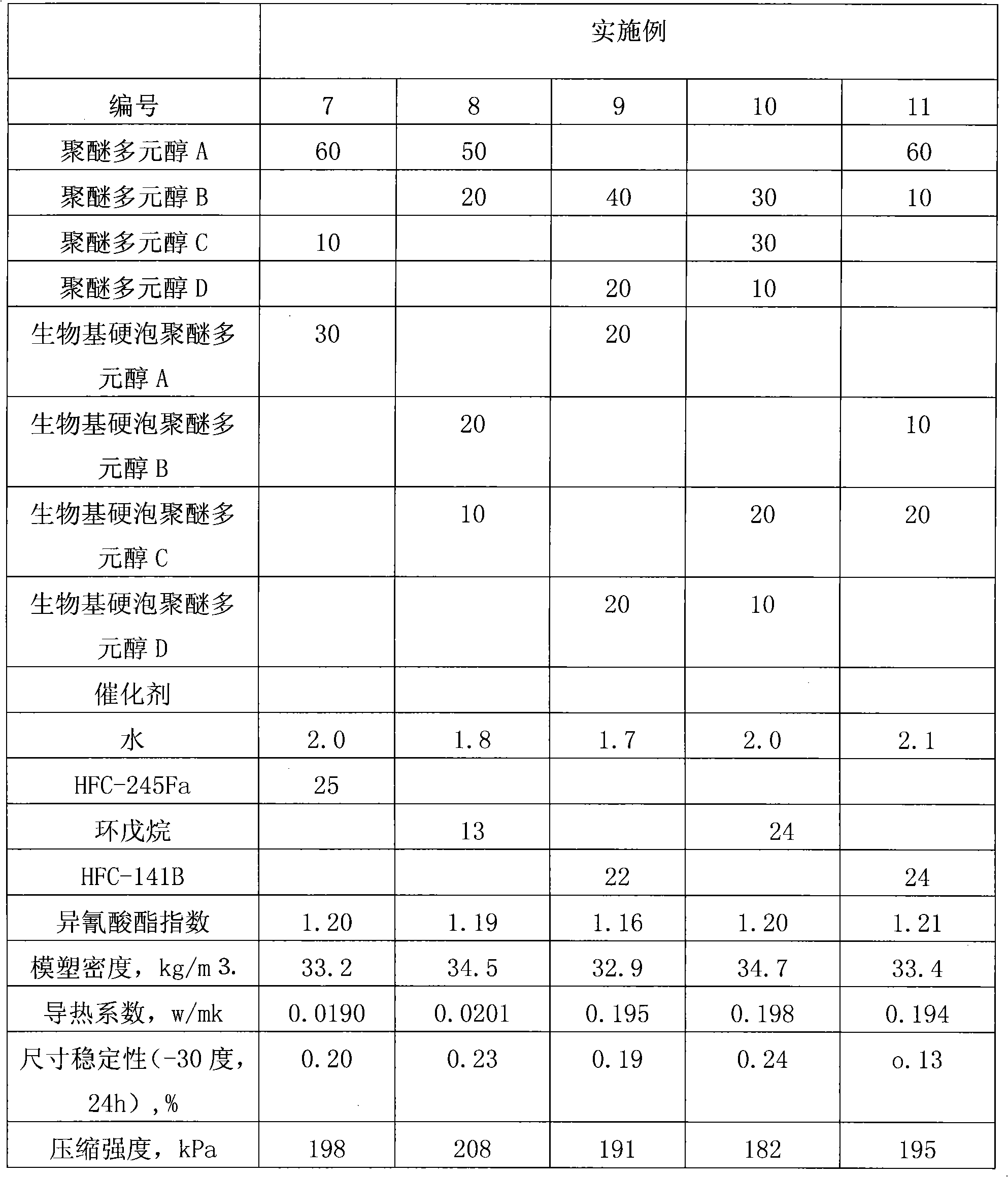

Examples

Embodiment 1

[0023] Add jatropha oil 1000g, 180 diethylene glycol, and 4g sodium hydroxide in a 2L glass kettle, stir and heat up to 170 degrees, react for 3 hours, detect the hydroxyl value, and discharge.

[0024] Modified jatropha oil A hydroxyl value: 126mgKOH / g

Embodiment 2

[0026] Add jatropha oil 1000g, 140 g of pentaerythritol, 5 g of potassium hydroxide in a 2L glass kettle, stir and heat up to 170 degrees, react for 3 hours, detect the hydroxyl value, and discharge.

[0027] Modified jatropha oil B hydroxyl value: 199mgKOH / g

Embodiment 3

[0029] Add jatropha oil 1000g, 160 g of triethanolamine, 6 g of calcium hydroxide in a 2L glass kettle, stir and heat up to 170 degrees, react for 3 hours, detect the hydroxyl value, and discharge.

[0030] Modified jatropha oil C hydroxyl value: 231mgKOH / g

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com