High temperature resistant automobile special putty not influencing adhesion and preparation method thereof

A technology with high temperature resistance and adhesion, which is applied in the direction of filling slurry, etc., can solve the problems of poor adhesion, flying dust, and pollution of the vehicle body, so as to improve the grinding and storage properties, smooth the grinding, and have a wide range of applications Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

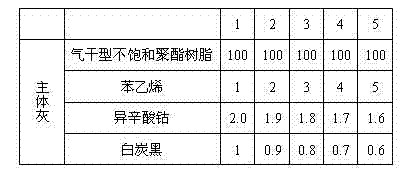

[0022] Embodiment 1-5 Preparation of air-drying type unsaturated polyester resin

[0023] (1) Air-drying type unsaturated polyester resin, raw materials used for preparation are shown in Table 1 (unit: gram):

[0024] Table 1

[0025]

[0026] (2) Preparation of air-drying unsaturated polyester resin:

[0027] a. Mix diethylene glycol, triethylene glycol, tetrahydrophthalic anhydride, dicyclopentadiene, maleic anhydride and trimethylolpropane diallyl ether, and slowly heat up to 200±5°C for 3-5 hours , keep the esterification;

[0028] b. When the acid value is below 40, lower the temperature to 130°C, put it into the dilution tank that has been added with styrene, add hydroquinone and copper naphthenate at the same time, stir evenly, cool down and put it in a barrel, and then the air-dried unsaturated polyester resin.

Embodiment 6-10

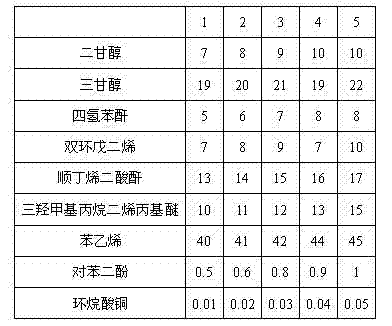

[0029] Example 6-10 Preparation of special putty for automobiles

[0030] (1) Prepare raw materials as shown in Table 2 (unit: gram):

[0031] Table 2

[0032]

[0033]

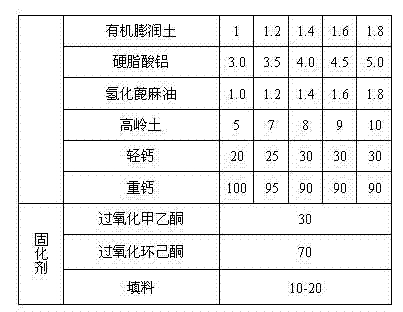

[0034] (2) Preparation of special putty for automobiles:

[0035] Add air-drying unsaturated polyester resin, styrene, cobalt isooctanoate, white carbon black, organic bentonite, aluminum stearate, hydrogenated castor oil, kaolin and heavy calcium into the tank in order and stir evenly. After measuring the consistency, The finished product is obtained by three-roll rolling once, and it can be packed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com