Preparation method of microbial oil

A microbial oil and oil-producing microorganism technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of prolonged fermentation cycle and reduced efficiency, and achieve the effects of overcoming inhibition, improving efficiency, and saving cultivated land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

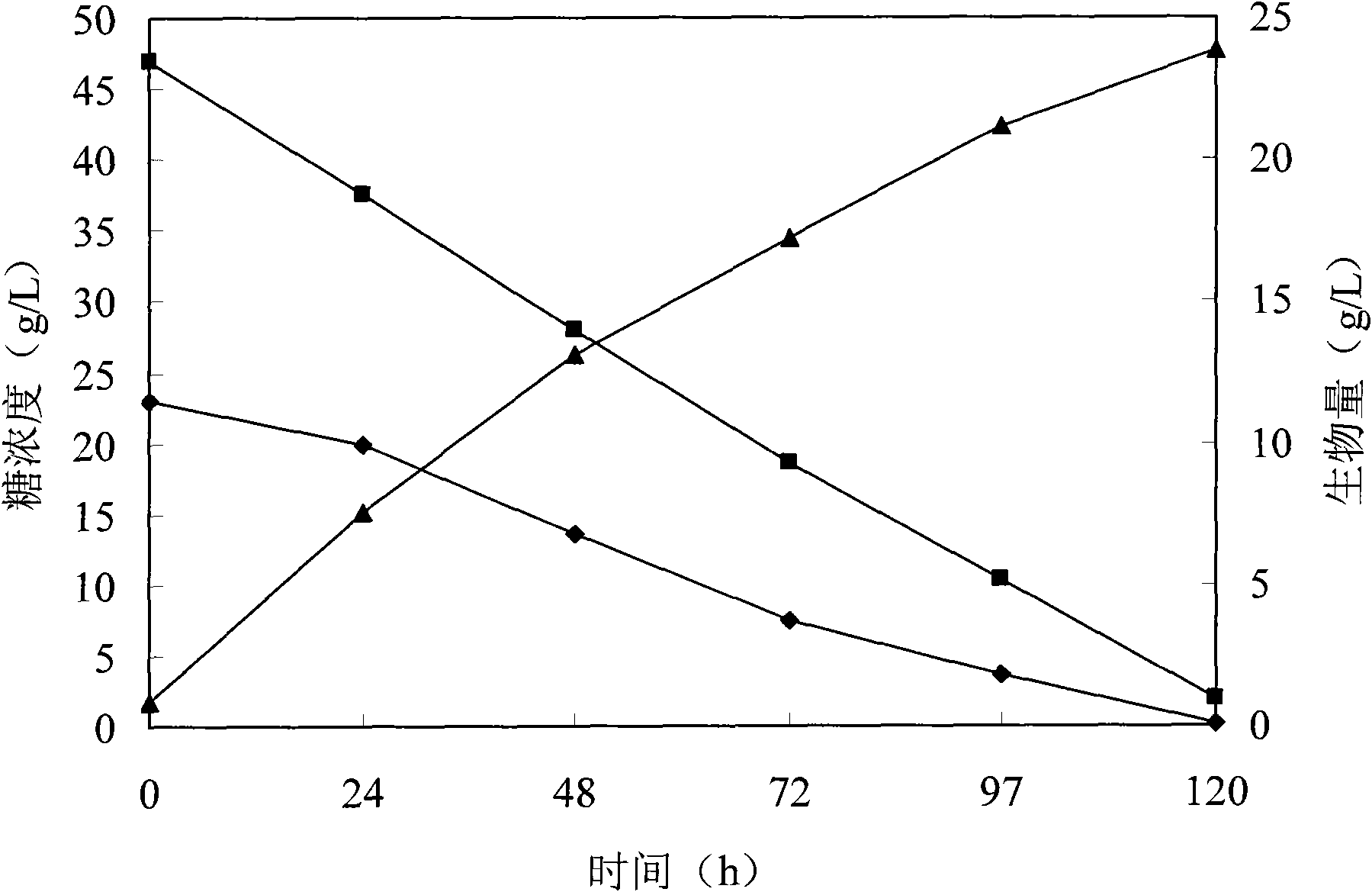

[0023] 1) Mix glucose and xylose into a mixed sugar solution, glucose 47g / L, xylose 23g / L, add 1.0g / L yeast powder, 0.1g / L ammonium chloride, 1.0g / L magnesium chloride, 0.1g / L Sodium sulfate, 11.8g / L potassium dihydrogen phosphate, 3.7g / L dipotassium hydrogen phosphate, trace element solution 1% (v / v), the balance is water, pH 6.0, and the obtained medium is sterilized at 121°C for 15 minutes for later use ;

[0024]2) Oleaginous yeast Trichosporon cutaneum AS 2.571 (purchased from China Common Microorganism Culture Collection Management Center) was cultured in a liquid seed medium at 30°C and 200 rpm for 20 hours with shaking;

[0025] 3) Introduce the oleaginous microorganism seed solution prepared in step (2) into the medium described in step (1), inoculum size 10% (v / v), and aerobically culture at 30° C. for 120 h;

[0026] 4) Terminate the fermentation. At this time, the residual glucose and xylose concentrations in the fermentation broth are respectively 0.1g / L and 1.9g...

Embodiment 2

[0028] 1) Mix glucose and xylose into a mixed sugar solution, glucose 10g / L, xylose 10g / L, add 2g / L yeast powder, 0.5g / L ammonium chloride, 0.2g / L magnesium chloride, 0.1g / L sulfuric acid Sodium, 0.4g / L potassium dihydrogen phosphate, 0.1g / L dipotassium hydrogen phosphate, trace element solution 1% (v / v), pH 5.0, the obtained culture medium was sterilized at 121°C for 15 minutes before use;

[0029] 2) Oleaginous yeast Rhodosporidium toruloides AS 2.1389 (purchased from China General Microorganism Culture Collection Management Center) was cultured in a liquid seed medium at 30°C and 200 rpm for 18 hours with shaking;

[0030] 3) Introducing the oleaginous microorganism seed solution prepared in step (2) into the culture medium described in step (1), with an inoculum size of 2% (v / v), and culturing with aeration at 25°C for 60 hours;

[0031] 4) Terminate the fermentation. At this time, the residual glucose and xylose concentrations in the fermentation broth were 0.1g / L and 1.2...

Embodiment 3

[0033] 1) Mix glucose and xylose into a mixed sugar solution, glucose 10g / L, xylose 50g / L, add 0.7g / L yeast powder, 0.2g / L ammonium chloride, 1.1g / L magnesium chloride, 0.5g / L Sodium sulfate, 8g / L potassium dihydrogen phosphate, 2g / L dipotassium hydrogen phosphate, 1% (v / v) trace element solution, pH 6.5, the obtained culture medium was sterilized at 121°C for 15 minutes for later use;

[0034] 2) Oleaginous yeast Cryptococcus curvatus ATCC 20509 (purchased from the American Type Culture Collection) was cultured in a liquid seed medium at 30° C. and 200 rpm for 24 hours with shaking;

[0035] 3) Introducing the oleaginous microorganism seed solution prepared in step (2) into the medium described in step (1), with an inoculum size of 5% (v / v), and aerated culture at 28°C for 144 hours;

[0036] 4) termination of fermentation, now residual glucose and xylose concentrations in the fermented liquid were 0g / L, 6.6g / L; carry out post-treatment according to the method of Example 1, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com